Tappet centering device for perforating machine

A centering device, piercing machine technology, applied in the direction of mandrel, metal rolling, manufacturing tools, etc., can solve the problems of ejector rod bending, inaccurate positioning, etc., and achieve the effect of improving product quality, preventing bending, and accurate centering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

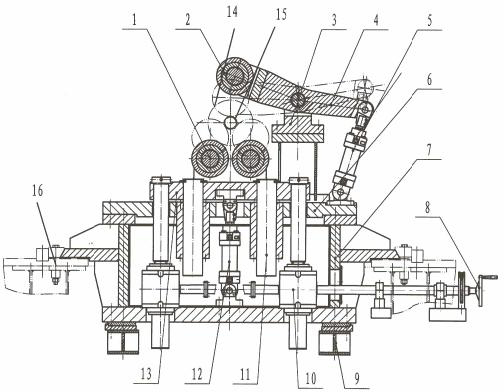

[0009] A centering device for the head of a piercing machine, comprising a second-stage base 16 in the background, a centering device base frame 7 fixedly arranged on the second-stage base 16 in the background, and two sets of Lifting screw device 10, two lifting screw devices 10 are connected together with hand wheel 8 through leading screw, the upward output shaft of two lifting screw devices 10 passes through the top surface of centering device chassis 7 and supports The roller supports 13 are fixedly connected together, and the lifting of the support roller supports 13 can be realized by adjusting the hand wheel 8 . A lifting guide rod 11 is arranged between the top surface of the centering device chassis 7 and the support roller support 13, so that the lifting of the support roller support 13 is completed under the guidance of the lifting guide rod 11. Two support rollers 1 are arranged in parallel on the support roller support 13 along the direction of the punching machi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com