Omnidirectional imaging-based method and system for detecting inner wall of steel pipe

A steel pipe inner wall and panoramic imaging technology, which is applied to measuring devices, material analysis through optical means, instruments, etc., can solve the problems of inability to guarantee the surface quality of steel pipes, limited observation distance of inspectors, and low detection efficiency, and achieve inner wall detection The effect is good, the image processing speed is fast, and the effect of overcoming high labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

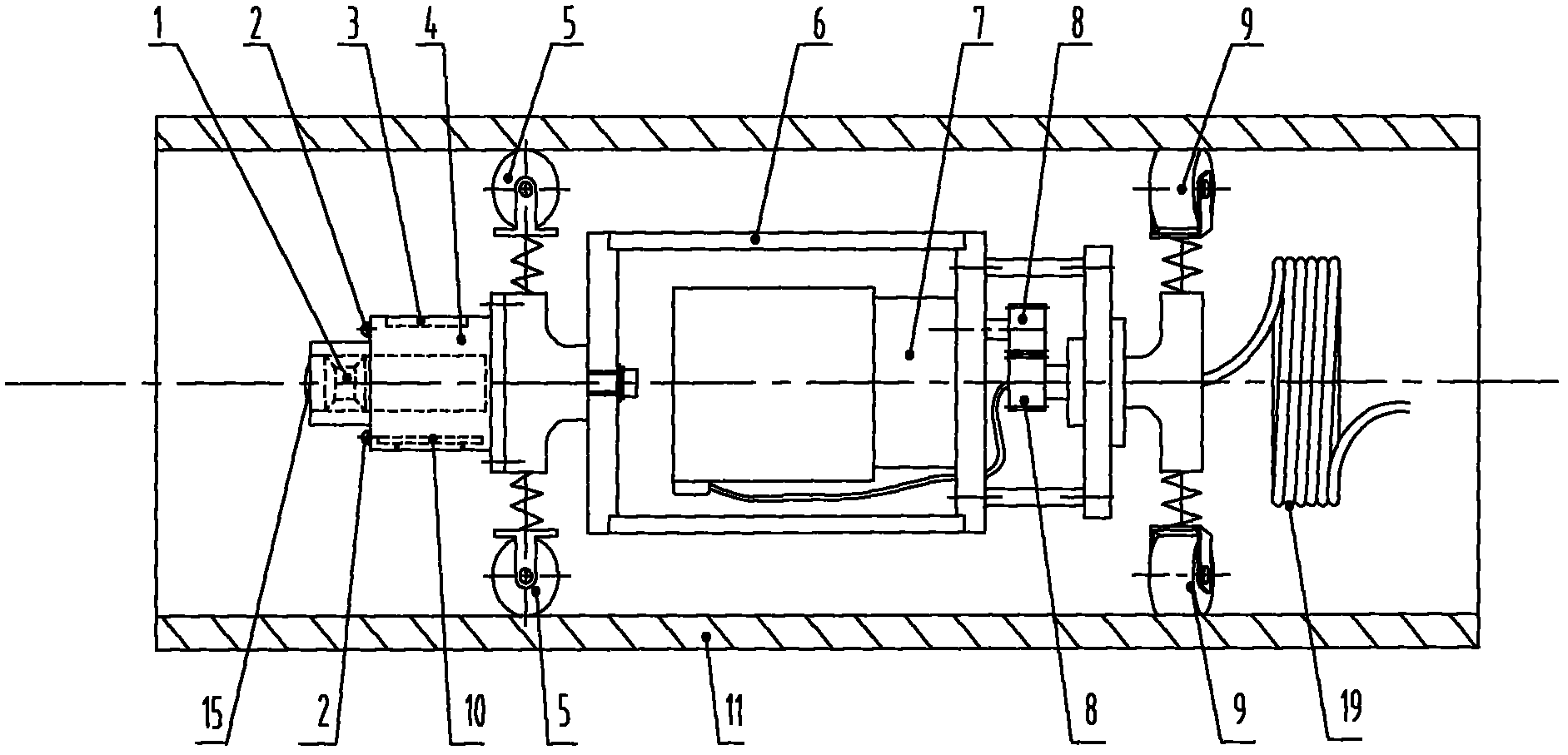

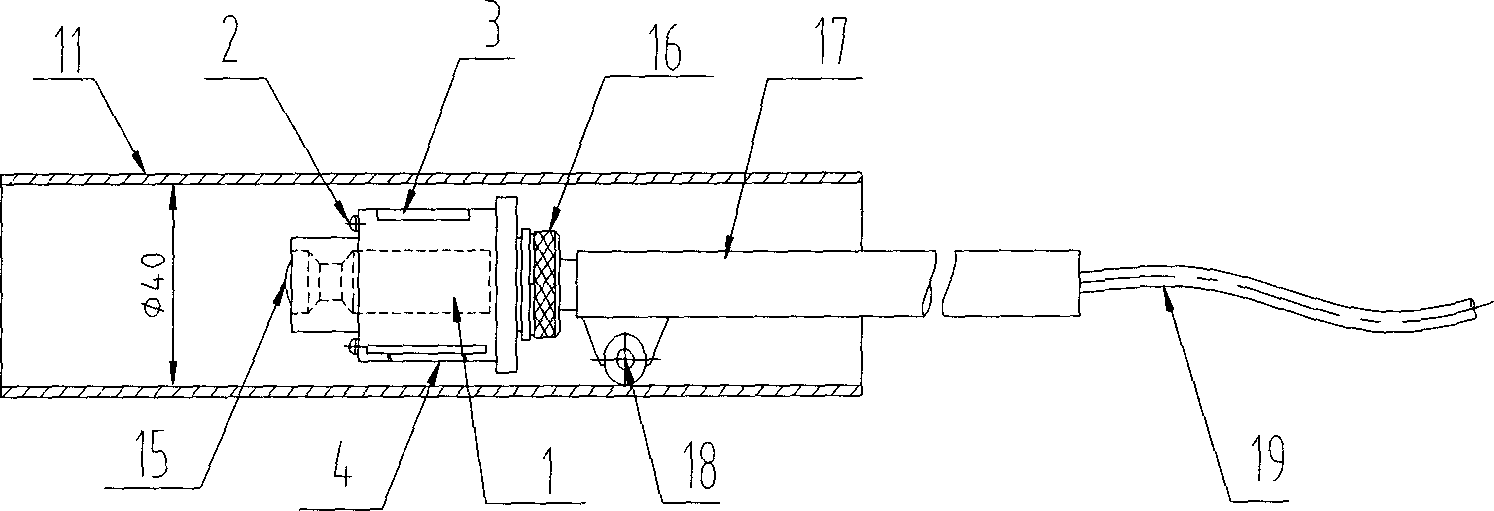

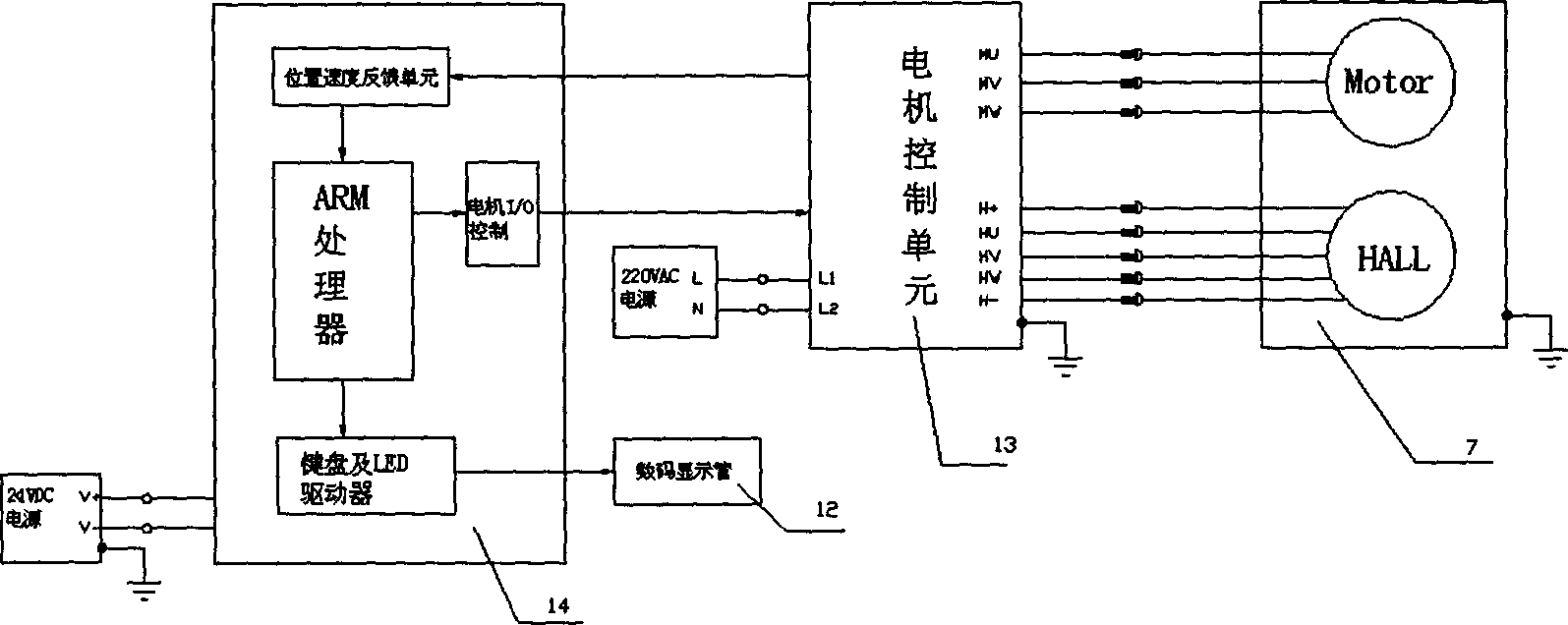

[0025] Such as figure 1 As shown, in the steel pipe 11 under test, the panoramic camera composed of the CCD / CMOS photosensitive assembly 1 and the PAL panoramic ring lens 15 is installed in the camera box 4, and the four corners of the camera box 4 outsides near the CCD / CMOS photosensitive assembly 1 are installed respectively. LED light 2 is arranged, rechargeable battery 3 or LED charging circuit board 10 are installed in the camera box 4, and the outside of the camera box 4 away from the CCD / CMOS photosensitive component 1 is connected with one end of the first driving bracket, and the other end of the first driving bracket is connected with the motor One end of the support 6 is connected, the other end of the motor support 6 is connected with the first drive support through the second drive support connection frame, the two sides of the first drive ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com