Vanillin ester condensed 1,3-butanediol and preparation method thereof

A technology of butanediol and vanillin, which is applied in the fields of essential oil/perfume, fat production, organic chemistry, etc., can solve the problems of blue purple, decomposition, etc., and achieve the effect of simple preparation method, easy operation, and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

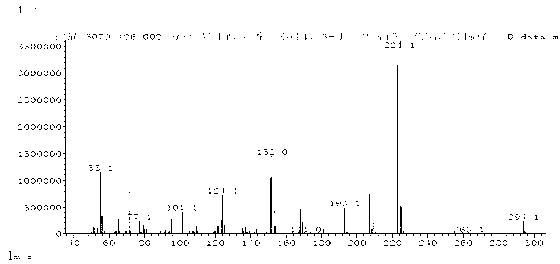

[0029] Using vanillin as raw material (0.30mol), toluene as solvent, the dosage is 100mL, add dropwise isobutyric anhydride (0.33mol) with a separatory funnel, dropwise for 1h, add Na 2 CO 3 Catalyst 0.02moL, react at 50°C for 2h. The reaction product was quenched with an equal volume of 15% NaOH solution, washed three times with saturated NaCl solution, the solvent was recovered by rotary evaporation, and fractions at 147-148°C (2.00kPa) were collected by vacuum distillation to obtain the product vanillin isobutyrate. The yield of vanillin isobutyrate is 95.9%, and after vacuum distillation, the total yield is 91.4%, and the purity is 98.5%. The reaction equation is:

[0030]

[0031] product of 1 H NMR data: 1.35~1.37 (d, J=6Hz, 6H, two methyl-CH 3 ), 2.79~2.93 (m, J=6Hz, 1H, -CH on methine), 3.91 (s, 3H, -CH on methoxy 3 ), 7.19~7.22 (dd, J=3Hz, 9Hz, 1H, H on the methoxy p-position benzene ring), 7.45~7.47 (d, J=9Hz, 1H, -OCOCH-o-position H on the benzene ring), 7....

Embodiment 2

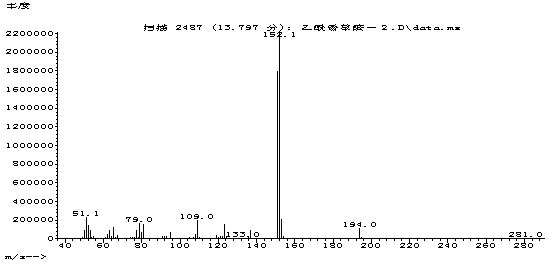

[0040] Using vanillin as raw material (0.30mol), toluene as solvent, the dosage is 100mL, add acetic anhydride (0.33mol) dropwise with a separatory funnel, drop after 1h, add Na 2 CO 3 Catalyst 0.02moL, react at 50°C for 2h. The reaction equation is as follows:

[0041]

[0042] The reaction product was quenched with an equal volume of 15% NaOH solution, washed three times with hot saturated NaCl solution, the solvent was recovered by rotary evaporation, recrystallized from ethanol, and dried in vacuo to obtain the product acetylvanillin.

[0043] The resulting product is carried out infrared analysis (tablet method, v / cm -1 ): 3017.15, 2967.87, 2944.09, 2914.23 and 2847.03 (C-H stretching vibration peaks on methyl and benzene rings); 2754.13 (formaldehyde C-H stretching vibration peaks); 1755.50 (carbonyl C=O stretching vibration peaks); 1690.76 (aldehyde C = O stretching vibration peak); 1598.17, 1507.03 and 1470.94 (the stretching vibration peak of the C=C skeleton of...

Embodiment 3

[0050] Preparation of solid superacid catalyst: Weigh a certain amount of ZrOCl 2 wxya 2 O, add deionized water and keep stirring until completely dissolved. Continue to stir and slowly add concentrated ammonia water to precipitate the solution, adjust the pH to 8-9, stir for a while, and leave it for 24 hours to age. Repeated decantation, suction filtration, washing to no Cl - exists (with AgNO 3 solution testing). The precipitate was dried at 105 °C for 24 h, and ground to below 100 mesh. With 1mol / L H 2 SO 4 The solution was soaked for 24h, and the excess H was removed by filtration. 2 SO 4 solution. Dry at 105°C for 24h to obtain The solid superacid catalyst is placed in a desiccator after cooling. Roast at 450°C for 3h before use.

[0051] Preparation of solid superacid catalyst: Weigh a certain amount of ZrOCl 2 wxya 2 O and TiCl 4 , making n(Ti):n(Zr)=1:6, 1:3, 1:1, 3:1 and 6:1 in turn to obtain five kinds of composite solid superacid catalysts with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com