Manufacturing process of decorative winebottle

A production process and wine bottle technology, applied in the field of B65D, can solve the problems of residual stress of the wine bottle body, waste of energy, and lower production efficiency, so as to reduce the burst rate and explosion rate, ensure product quality, and improve production qualification rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

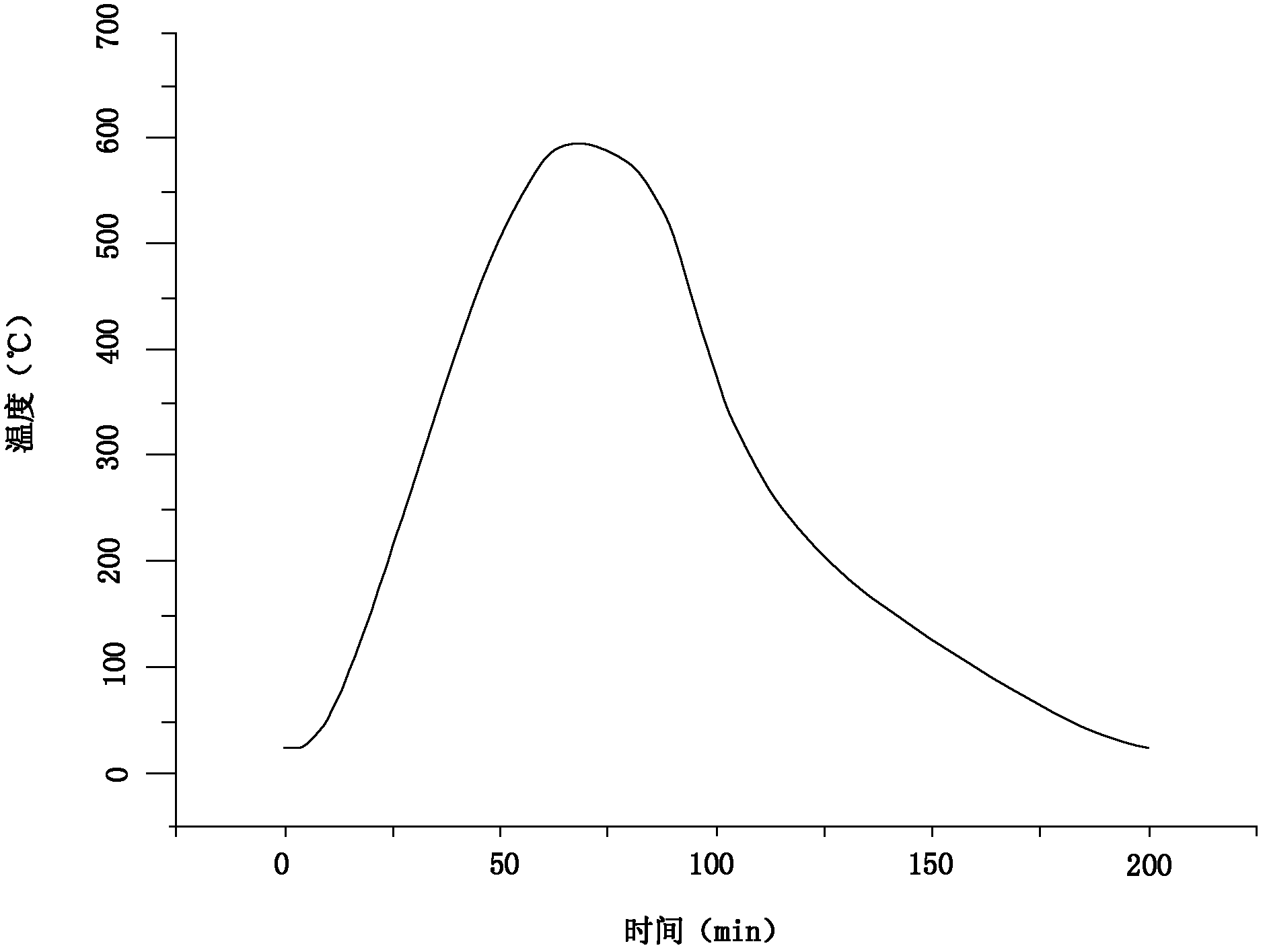

[0038] Put the wine bottle in the roasting furnace, and preheat the wine bottle from room temperature to 282°C after 45 minutes;

[0039] After 35 minutes, the temperature was raised to 585°C;

[0040] keep warm for 15 minutes;

[0041] Then the wine bottle is cooled down to room temperature by natural cooling;

[0042] After 8 hours of production in one shift, the bursting rate of the wine bottle was 0.03%, and the popping rate was 1.80%. Points and so on, the pass rate of the final bottle reached 93.2%.

Embodiment 2

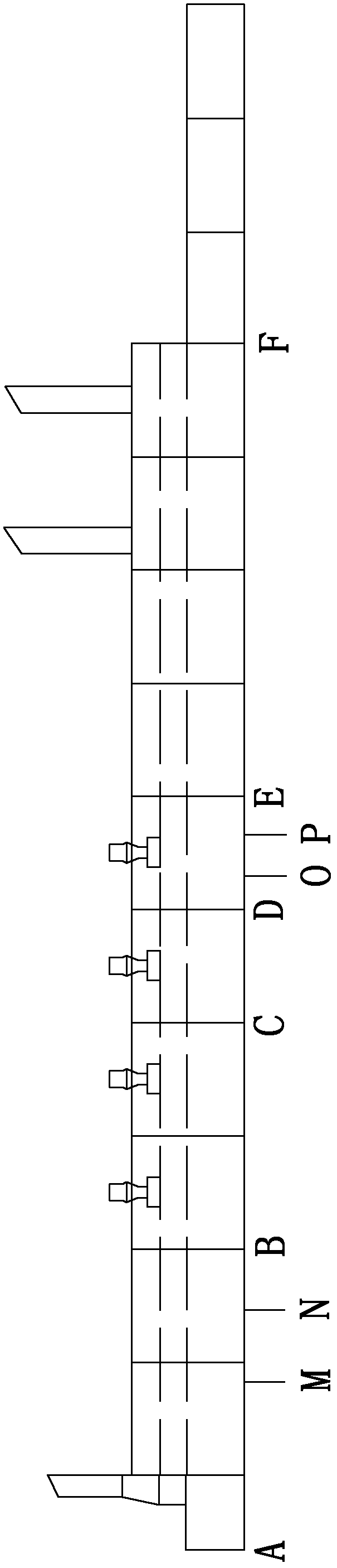

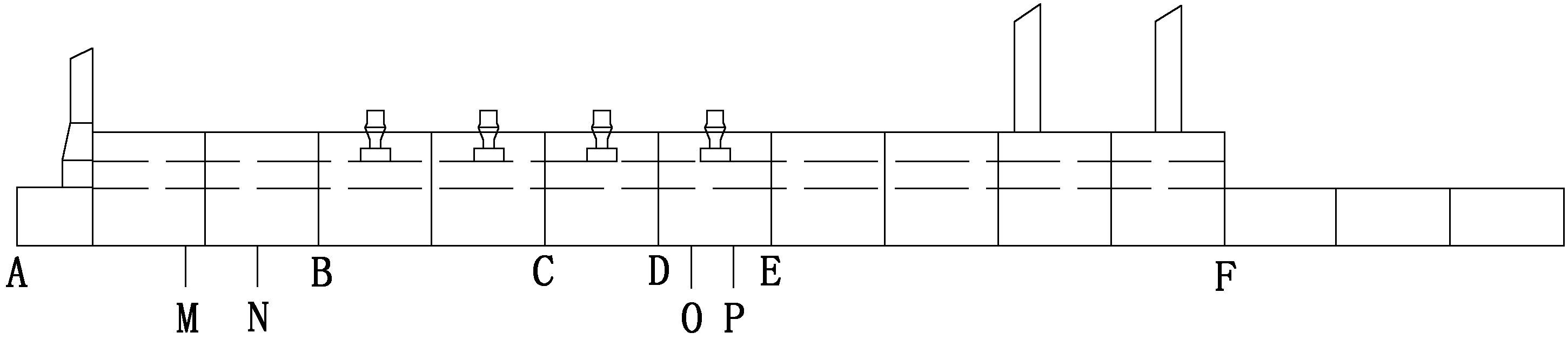

[0044] Put the wine bottle on the steel mesh belt that can move in the baking furnace, start the steel mesh belt, so that the wine bottle moves at a constant speed in the baking furnace, and after 45 minutes from figure 1 Point A in the middle moves to point B, so that the wine bottle is gradually heated up and preheated to 282°C (the temperature of the previous point in the baking furnace is lower than the temperature of the latter point, and the temperature gradually increases);

[0045] Then move from point B to point C for 35 minutes to gradually heat up the wine bottle to 585°C (the temperature of the previous point in the baking furnace is lower than the temperature of the latter point, and the temperature gradually increases);

[0046] keep warm for 15 minutes;

[0047] Then the wine bottle is cooled down to room temperature by natural cooling;

[0048] After 8 hours of production in one shift, the bursting rate of the wine bottle was 0.02%, and the popping rate was 1....

Embodiment 3

[0050] Put the wine bottle on the steel mesh belt that can move in the baking furnace, start the steel mesh belt, so that the wine bottle moves at a constant speed in the baking furnace, and after 45 minutes from figure 1 Point A in the middle moves to point B, so that the wine bottle is gradually heated up and preheated to 282°C (the temperature of the previous point in the baking furnace is lower than the temperature of the latter point, and the temperature gradually increases);

[0051] Then move from point B to point C for 35 minutes to gradually heat up the wine bottle to 585°C (the temperature of the previous point in the baking furnace is lower than the temperature of the latter point, and the temperature gradually increases);

[0052] keep warm for 15 minutes;

[0053] Then gradually cool down the wine bottle to 575°C in 20 minutes (the temperature at the previous point in the baking furnace is greater than the temperature at the latter point, and the temperature gradu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com