Anti-explosion glass

An anti-explosion, glass technology, applied in the direction of shock, walls, buildings, etc., can solve the problems of not being able to buffer the glass, not protecting the corners of the glass, and not being firmly fixed between the glass and the wall.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

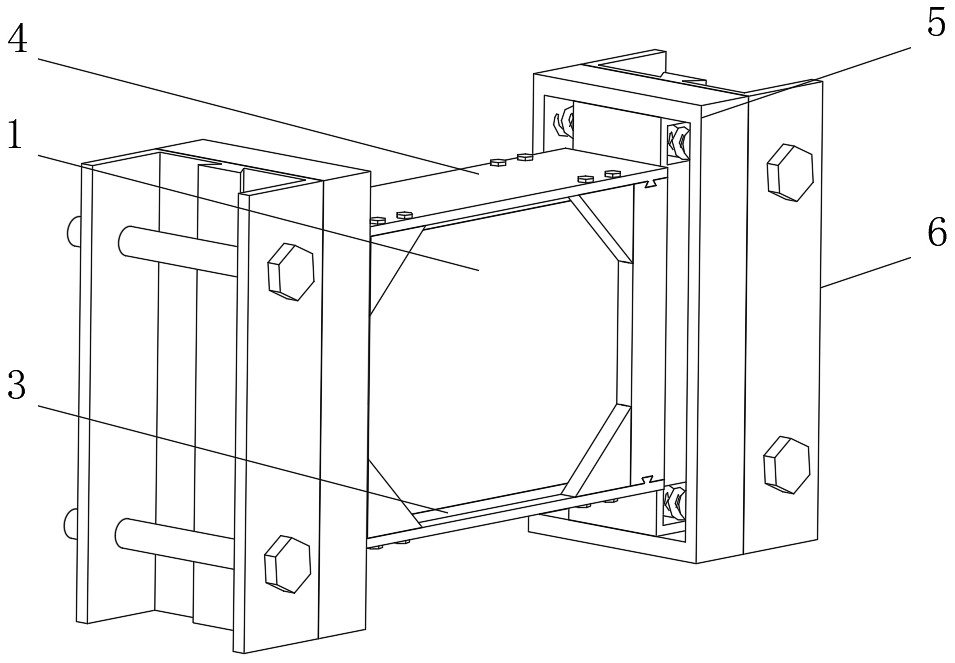

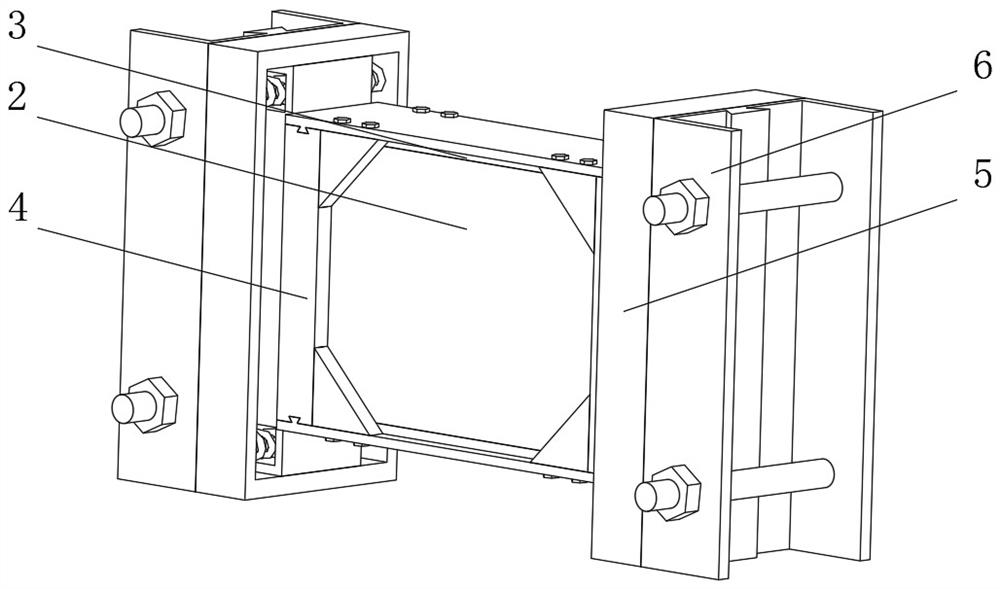

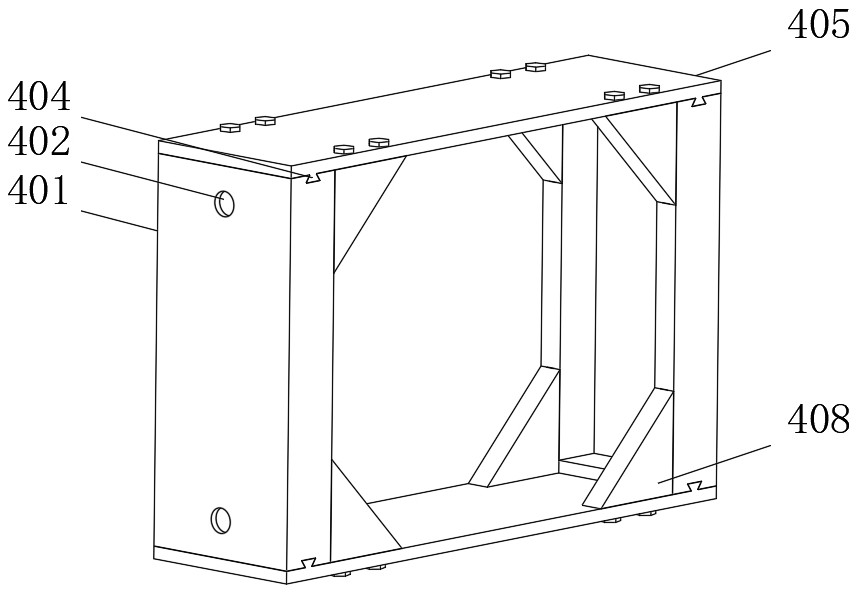

[0032] Embodiment 1: One end of the protective frame 401 is fixedly connected to one end of the main glass 1, one end of the protective frame 401 close to the main glass 1 is fixedly connected to one end of the soundproof glass 2, the outer side of the fixed block 404 is connected to the inner side of the fixed groove 403 Flexible connection, the upper end of fixed block 404 is fixedly connected with the lower end of fixed plate 405, the outside of slide block 407 is connected with the inner side of chute 406, and one end of slide block 407 is fixedly connected with an end of triangular plate 408, and the rear end of triangular plate 408 is connected with The front end of the main glass 1 is movably connected, and the first threaded rod 409 runs through the inside of the fixed plate 405. The triangular plate 408 is threaded; during use, at first the slide block 407 is put into the inside of the chute 406, and then the triangular plate 408 is pulled downwards, so that the triang...

Embodiment 2

[0033] Embodiment 2: One end of the protective frame 401 is movably connected with one end of the support block 501, the second threaded rod 502 runs through the inside of the support block 501, the second threaded rod 502 is threadedly connected with the support block 501, and the second threaded rod 502 extends to the threaded Inside the hole 402, the second threaded rod 502 is threadedly connected with the threaded hole 402, the protective frame 401 is fixedly connected with the support block 501 by the second threaded rod 502, the outer side of the limiting block 504 is fixedly connected with the inner side of the movable groove 503, and the limiting The front end of the block 504 is fixedly connected with the rear end of the buffer spring 505, the front end of the buffer spring 505 is fixedly connected with the inner side of the fixed frame 506, the outer side of the moving block 508 is movably connected with the inside of the limiting groove 507, and the lower end of the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com