L-RTM (Light-Resin Transfer Moulding) manufacture technology for glass fiber reinforced plastics wind power engine room cover

A wind turbine canopy and manufacturing process technology, applied in the field of L-RTM manufacturing process, can solve the problems of low labor intensity of workers, poor product performance stability, long production cycle, etc., saving human and material resources and time, and saving purchase and maintenance. , the effect of high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

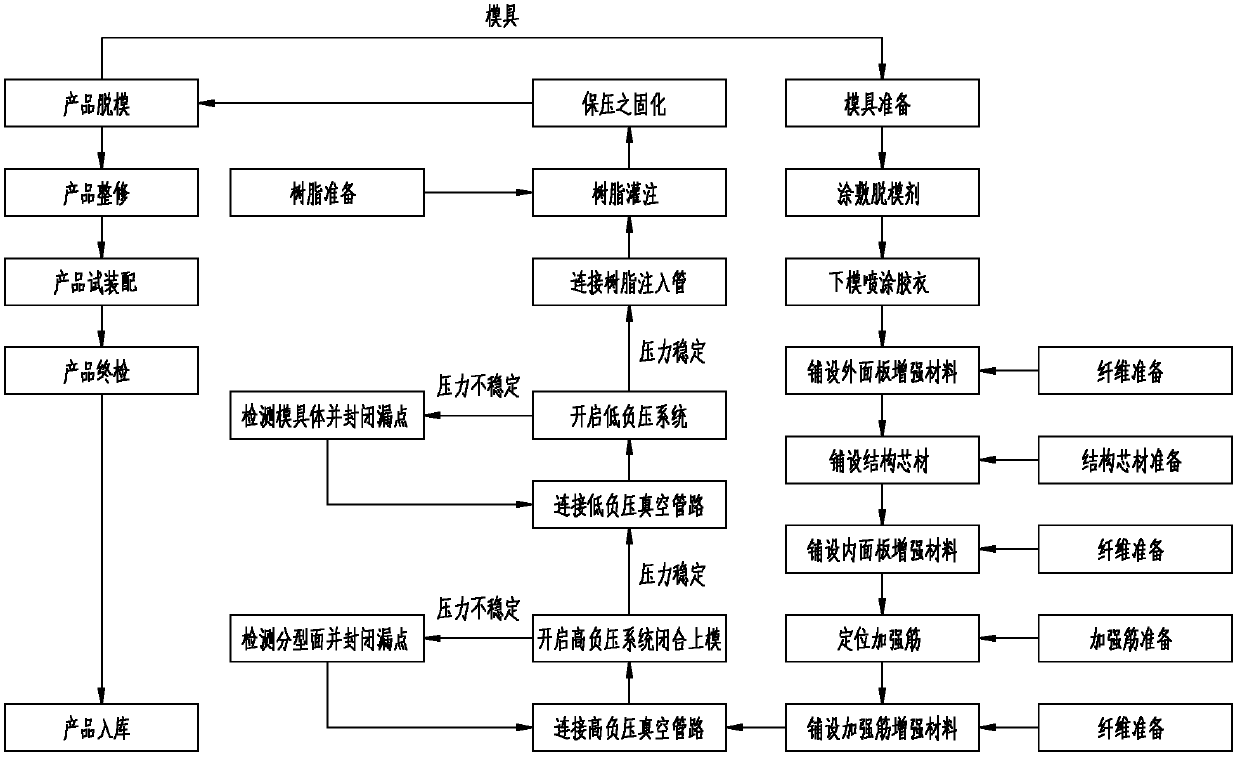

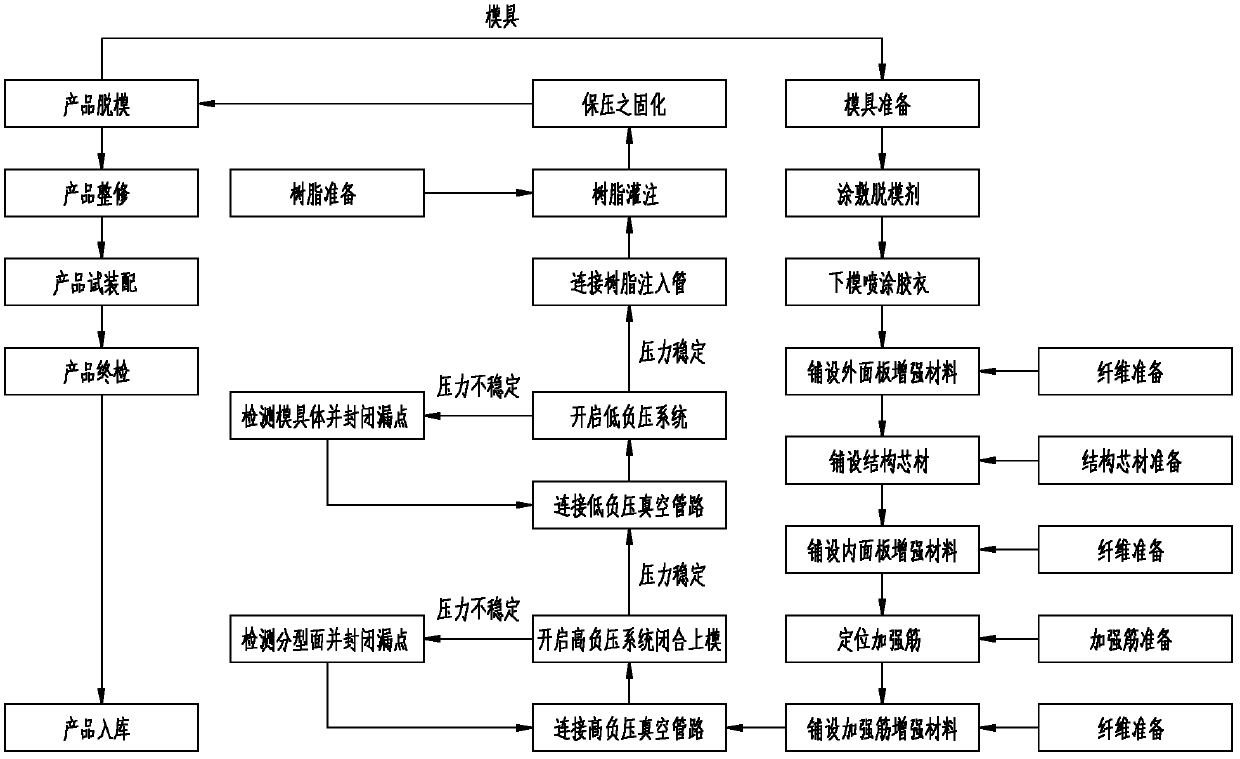

[0019] Fig. 1 is a block diagram of the technical process of the present invention, as shown in the figure: the L-RTM manufacturing process of the glass fiber reinforced plastic wind turbine cabin cover of the present embodiment includes mold processing, prefabricated part laying, mold closing and sealing, mold cavity vacuuming treatment, resin injection And demoulding trimming process, it is characterized in that: in described clamping sealing process, be provided with along the parting surface of mould, be used for mold clamping and the annular sealing chamber that mold cavity is sealed, communicate with described annular sealing cavity There is a high negative pressure system and a high negative pressure monitoring device. After vacuuming, the pressure value displayed by the high negative pressure monitoring device can be used to judge whether the annular sealing cavity is leaking; The cavity is connected with a low negative pressure system and a low negative pressure monito...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com