Method for manufacturing gallium nitride compound semiconductor, and semiconductor light emitting element

A manufacturing method, gallium nitride-based technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, chemical instruments and methods, etc., can solve the unrealistic characteristics of light-emitting elements, m-plane InGaN layer crystal defects and increased holes, Problems such as decreased crystallinity of the m-plane InGaN layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0134] As follows, while referring to Figure 14 , while describing an embodiment in which a semiconductor light-emitting element is manufactured according to the method for manufacturing a gallium nitride-based compound semiconductor of the present invention.

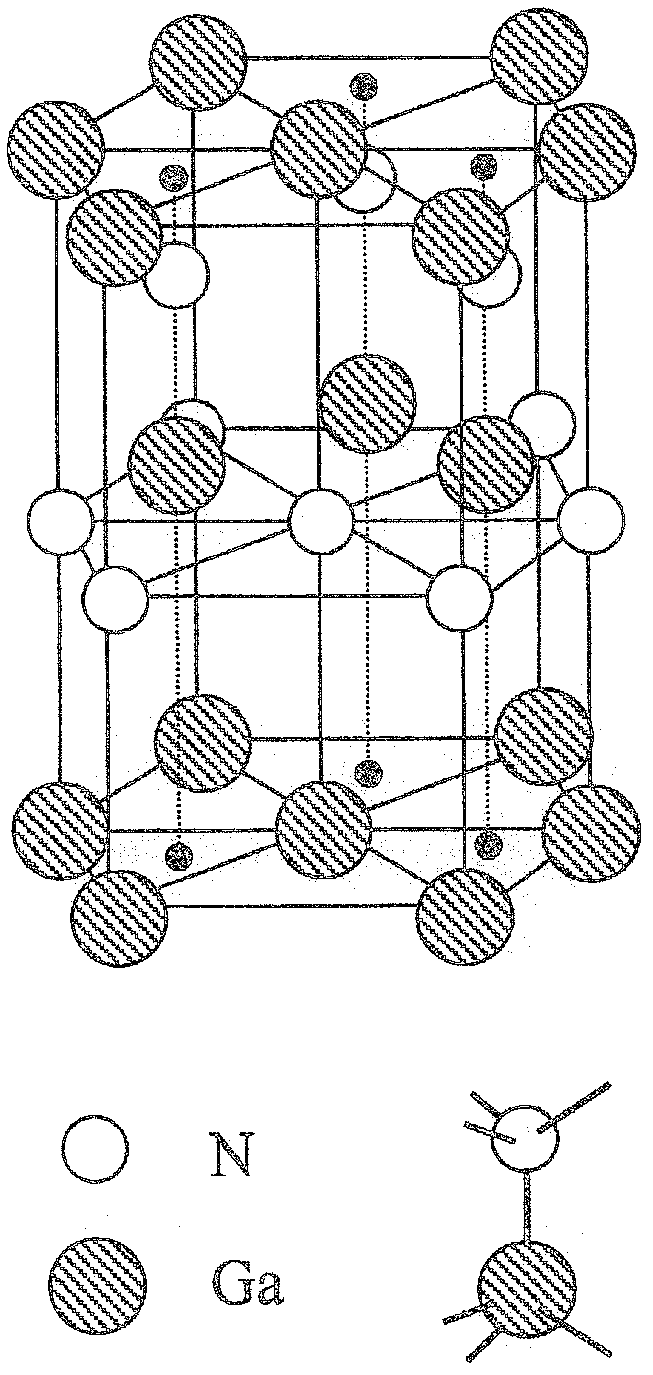

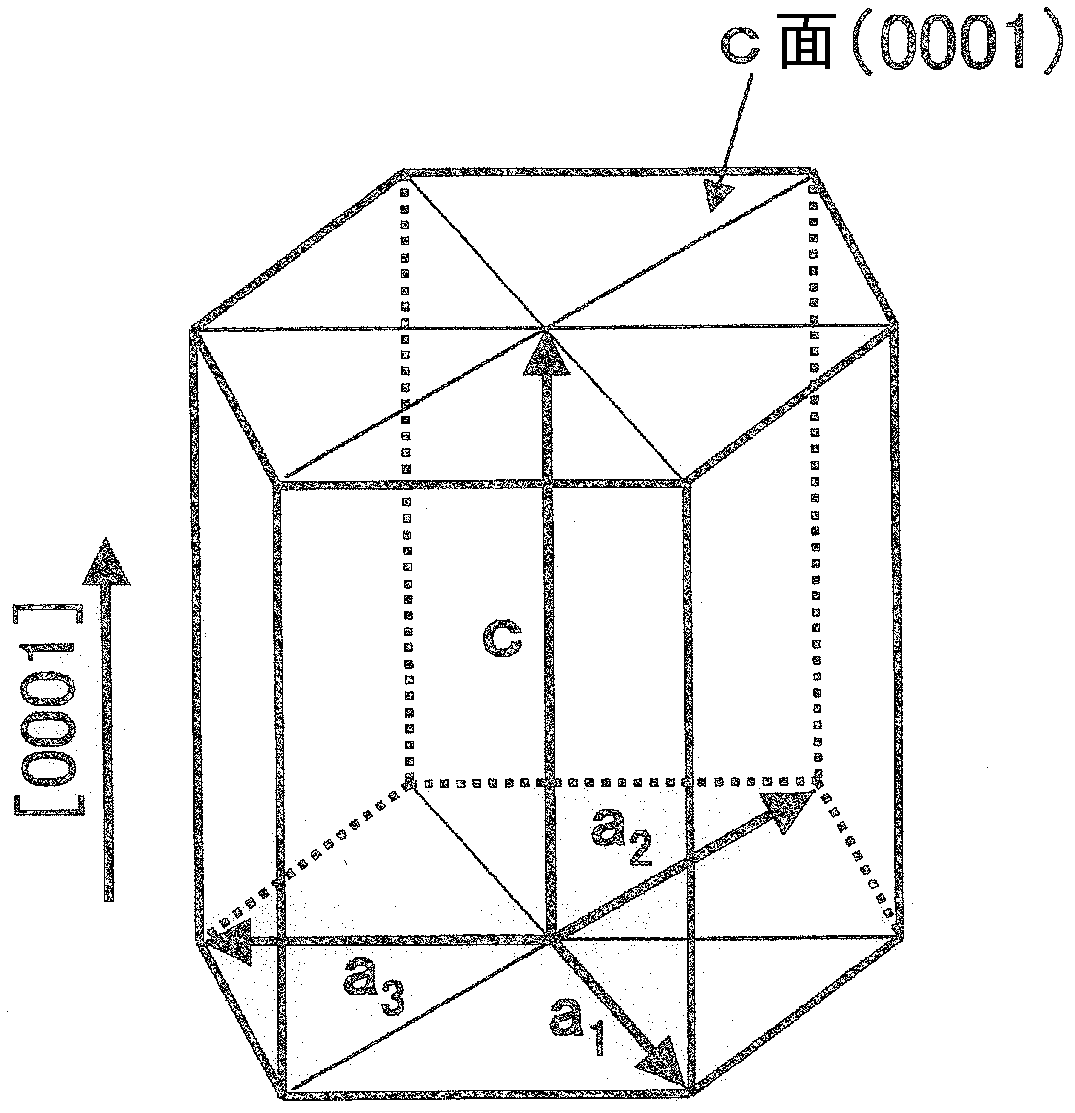

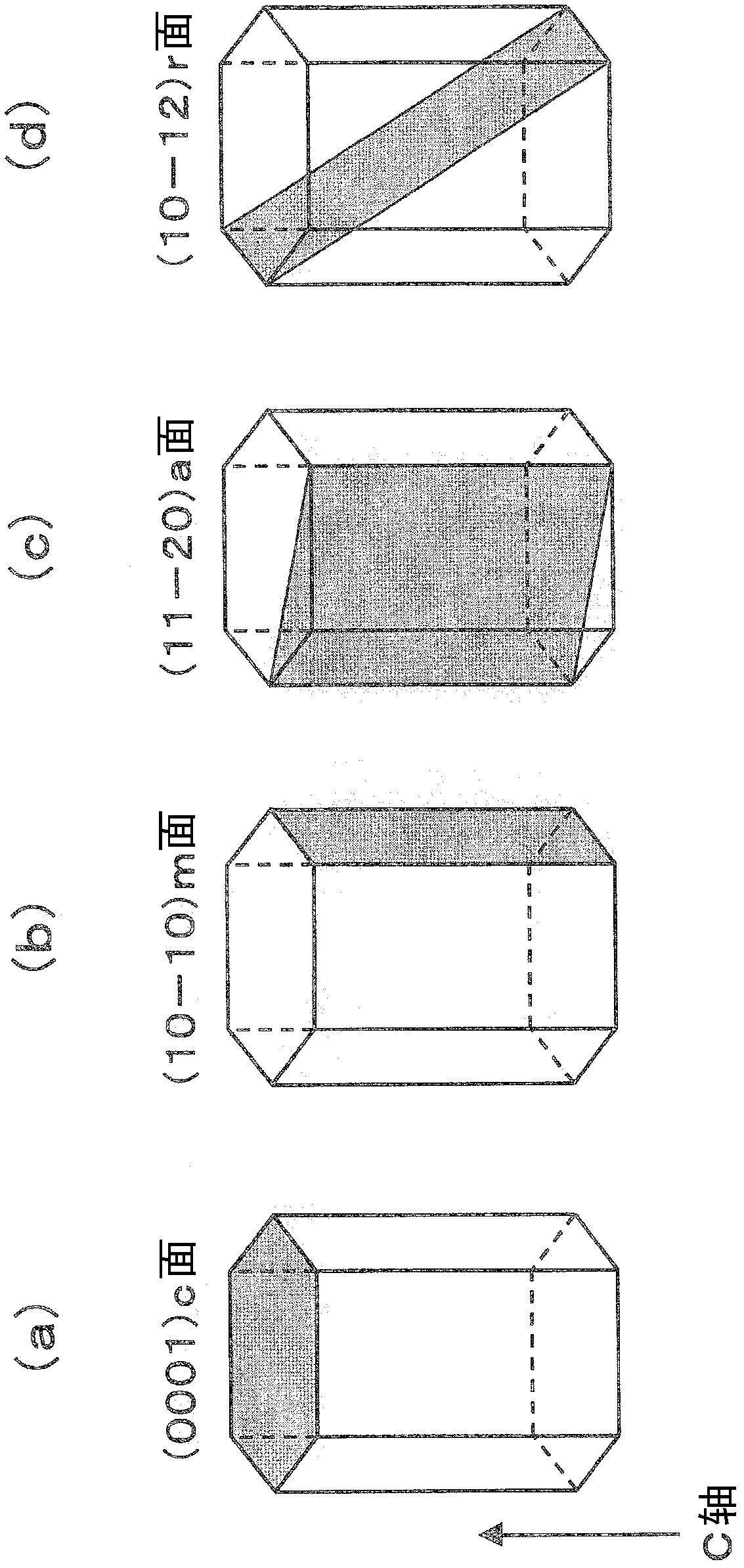

[0135] The substrate 101 for crystal growth used in this embodiment is a substrate on which gallium nitride (GaN) on the (10-10)m plane can grow. A self-supporting substrate of gallium nitride itself exhibiting an m-plane is most preferable, but a substrate exhibiting an m-plane in a 4H or 6H structure of silicon carbide (SiC) having a similar lattice constant may also be used. In addition, sapphire that also exhibits the m-plane may also be used. However, if a substance different from the gallium nitride-based compound semiconductor is used on the substrate, it is necessary to insert an appropriate intermediate layer or buffer layer between the gallium nitride-based compound semiconductor layer deposited on top.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com