Antifoulant for Impact Copolymers and Method

A technology of impact copolymerization and copolymer, which is applied in the field of multiphase copolymer and copolymer production, can solve problems such as harmful production efficiency, achieve the effect of reducing production failure time and inhibiting reactor fouling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

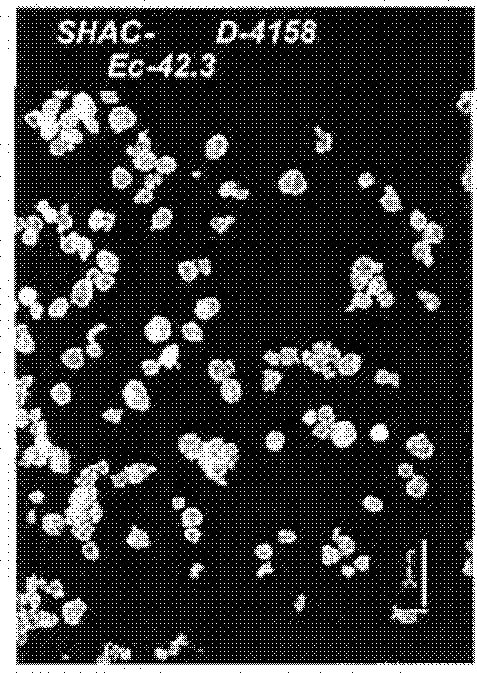

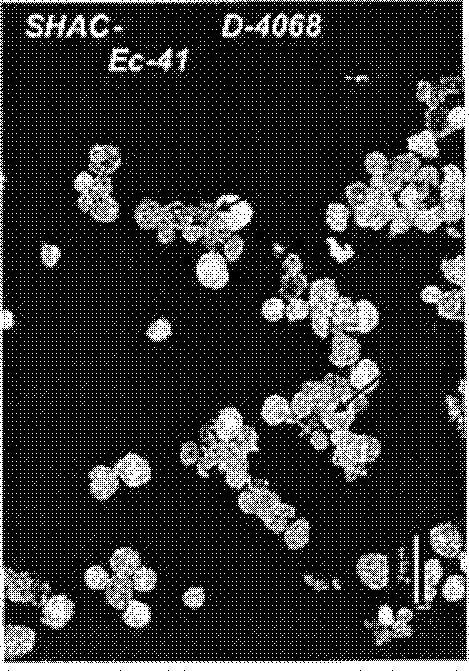

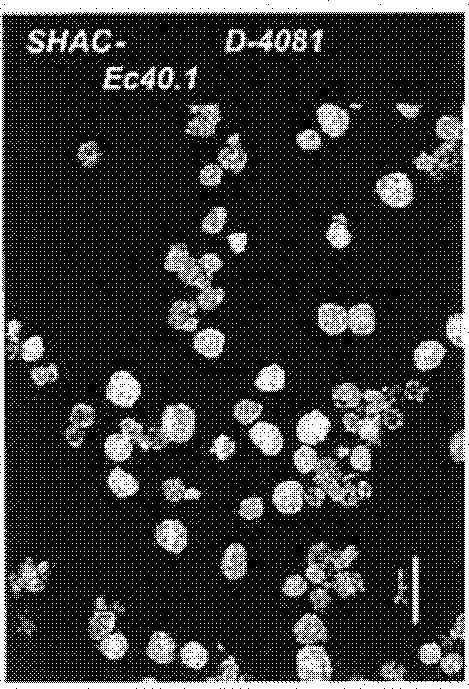

Image

Examples

Embodiment 1

[0143] Two polypropylene fluidized bed reactors are connected in series to produce propylene impact copolymer. The propylene impact copolymer comprises a propylene homopolymer produced in the first reactor (Reactor 1) and a propylene / ethylene copolymer produced in the second reactor (Reactor 2). The catalyst system is a Ziegler-Natta supported catalyst mixed with an aluminum alkyl activator and an external donor (selectivity control agent). Hydrogen was fed to both reactors simultaneously, controlling the melt flow. The selectivity control agent (SCA) fed to Reactor 1 comprised a mixture of 60 mol% isopropyl myristate and 40 mol% dicyclopentyldimethylsilane. A multi-component anti-fouling agent comprising 95 mol% isopropyl myristate and 5 mol% dicyclopentyldimethylsilane was fed into Reactor 2 to inhibit fouling and control rubber content (Fc). Table 1 shows the reactor conditions for the five tests (A-E). Tests A-E show that increasing amounts of multicomponent antifouling...

Embodiment 2

[0148] Two polypropylene fluidized bed reactors are connected in series to produce propylene impact copolymer. The propylene impact copolymer comprises a propylene homopolymer produced in the first reactor (Reactor 1) and a propylene / ethylene copolymer produced in the second reactor (Reactor 2). The catalyst system is a Ziegler-Natta supported catalyst mixed with an aluminum alkyl activator and an external donor (selectivity control agent). Hydrogen was fed to both reactors simultaneously, controlling the melt flow. The selectivity control agent (SCA) fed to Reactor 1 comprised a mixture of 60 mol% isopropyl myristate and 40 mol% dicyclopentyldimethylsilane. A multi-component anti-fouling agent comprising 95 mol% isopropyl myristate and 5 mol% n-propyltrimethylsilane was fed into Reactor 2 to inhibit fouling and control rubber content (Fc). Table 2 shows the reactor conditions for the three tests (F-H). For Tests F-H, increasing amounts of multicomponent antifouling agent (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com