Farina online digestor and digestion method thereof

A digester and starch technology, which is applied to digesters, textiles, papermaking, and fiber raw material processing, can solve the problems of high plant requirements, waste of energy, and low degree of automation, and achieve consistent quality assurance, reduce plant investment, and reduce The effect of labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings of the embodiments.

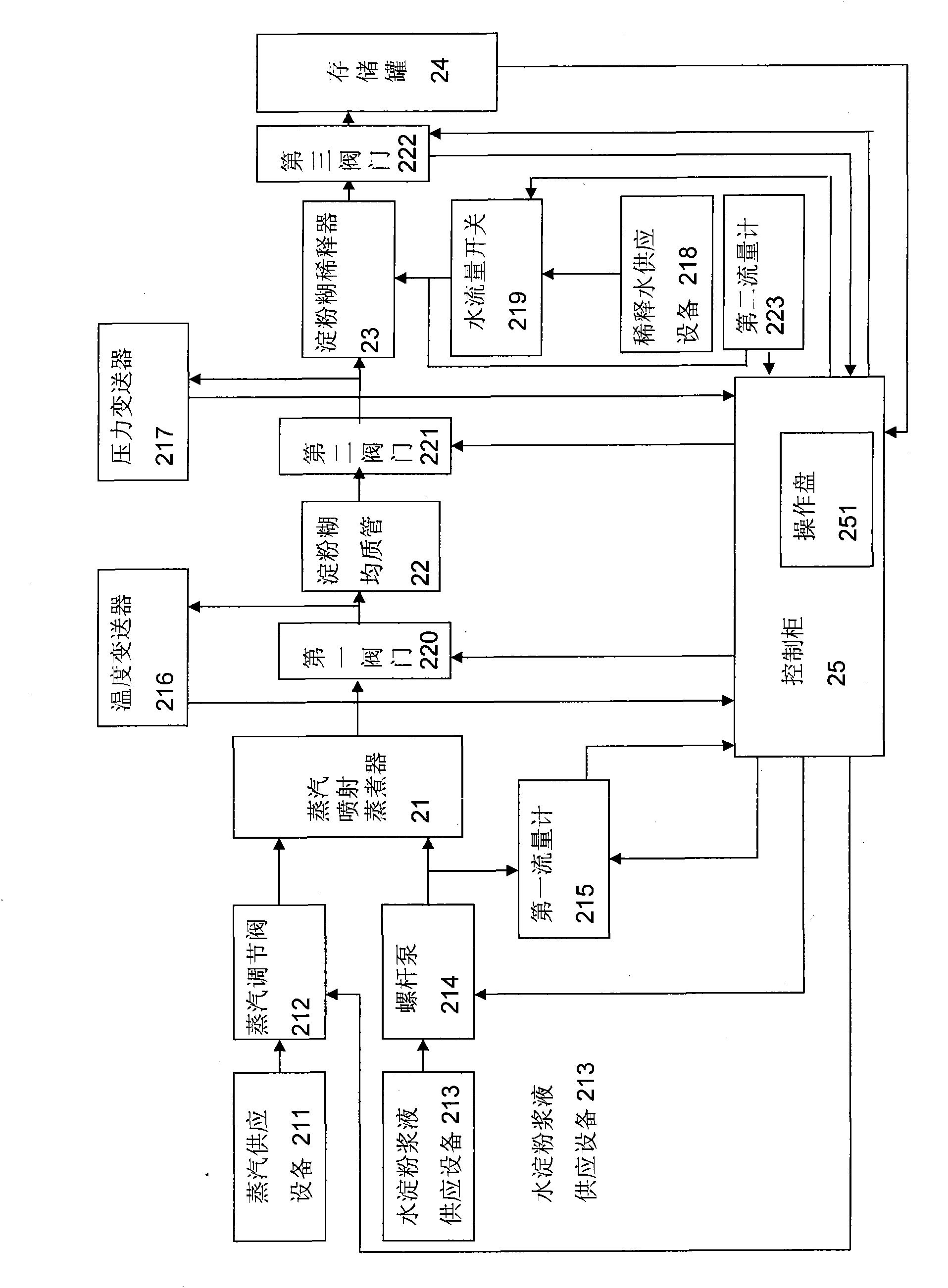

[0047] see figure 2 , as shown in the figure, the structure of the starch online cooker of the present invention is as follows:

[0048] The steam jet cooker 21 is a pipeline heater made of SS316 stainless steel. It has two input ports, one for steam input port and the other for water starch slurry input port. It has an output port for cooked starch The paste output port, the steam input port is connected with the steam supply equipment 211 that provides high-temperature steam through a pipeline, and the water starch slurry input port is connected with the water starch slurry supply equipment 213 that provides the prepared water starch slurry through a pipeline, and the The cooked starch paste output port outputs the cooked starch paste cooked by the steam jet cooker 21 . A steam regulating valve 212 (the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com