Esterifiable modification method of lignocelluloses and esterifiable modified lignocelluloses

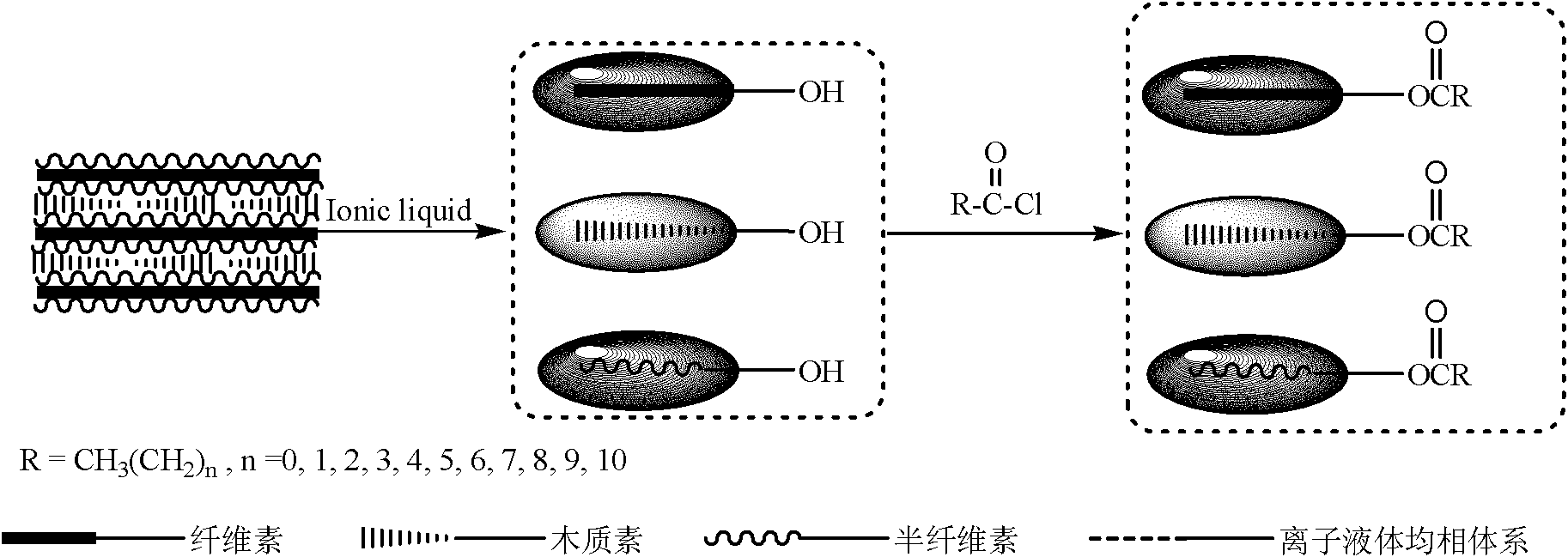

A technology for lignocellulose and esterification modification, which is applied in the field of preparation of lignocellulose esterification materials based on imidazolium-based ionic liquids, can solve problems such as restricting commercial applications, and achieve the effects of less impurity content and simple product purification treatment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] Embodiment 1: the preparation of ethyl esterified poplar lignocellulose

[0061] 1. Dissolving lignocellulose

[0062] 1) Add poplar wood powder into a ceramic pot with a volume of 2 L and 68 ceramic balls with a diameter of 15 mm, and grind the wood powder at room temperature (25°C) at a speed of 70 rpm for 48 hours to obtain Ball-milled poplar wood flour with particle size ≤50um;

[0063] 2) Put 0.5g of ball-milled poplar wood powder (the molar number of hydroxyl groups is 14.6mmol / g) and 9.5g of 1-butyl-3-methylimidazolium chloride salt in a 50mL three-necked bottle, turn on nitrogen, and carry out nitrogen protection. Put it in an oil bath and heat it with constant stirring, wherein the 1-butyl-3-methylimidazolium chloride salt dissolves into an ionic liquid, control the heating temperature of the oil bath to 110°C, and stir until the wood powder is completely dissolved in the ionic liquid.

[0064] 2. Esterification treatment

[0065] Stop heating, and when the ...

Embodiment 2

[0068] The preparation of embodiment 2 butylated poplar lignocellulose

[0069] 1. Dissolving lignocellulose

[0070] 1) Add poplar wood powder into a ceramic pot with a volume of 2 L and 68 ceramic balls with a diameter of 15 mm, and grind the wood powder at room temperature (25°C) at a speed of 70 rpm for 48 hours to obtain ≤50um ball-milled poplar wood flour;

[0071] 2) Put 0.5g of ball-milled poplar wood powder (the molar number of hydroxyl groups is 14.6mmol / g) and 9.5g of 1-butyl-3-methylimidazole acetate (placed in a 50mL three-necked bottle, connect to nitrogen, and carry out nitrogen protection, put The three-neck flask was heated in an oil bath and stirred continuously, in which 1-butyl-3-methylimidazole acetate was dissolved into an ionic liquid, and the temperature of the oil bath was controlled to be 130°C, and stirred until the wood powder was dissolved in the ionic liquid middle.

[0072] 2. Esterification treatment

[0073] Stop heating, and when the tempe...

Embodiment 3

[0079] The preparation of embodiment 3 butylated poplar lignocellulose

[0080] Except that the esterification reagent butyryl chloride used in the esterification treatment step was 7.3 mmol, the rest was the same as in Example 2. The mass increase percentage of the prepared butylated poplar lignocellulose is 11.9%, and the hydroxyl substitution degree is 1.7mmol / g.

[0081] Scanning electron microscopy was used to detect the morphology of esterified modified lignocellulose, such as Figure 5 Shown in B4a, B4b, B4c in.

[0082] Figure 5 Middle (B4a) is a scanning electron micrograph of esterified modified lignocellulose magnified 1000 times; Figure 5 Middle (B4b) is a scanning electron micrograph of esterified modified lignocellulose magnified 5000 times; Figure 5 Middle (B4c) is a scanning electron micrograph of esterified modified lignocellulose magnified 10,000 times.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com