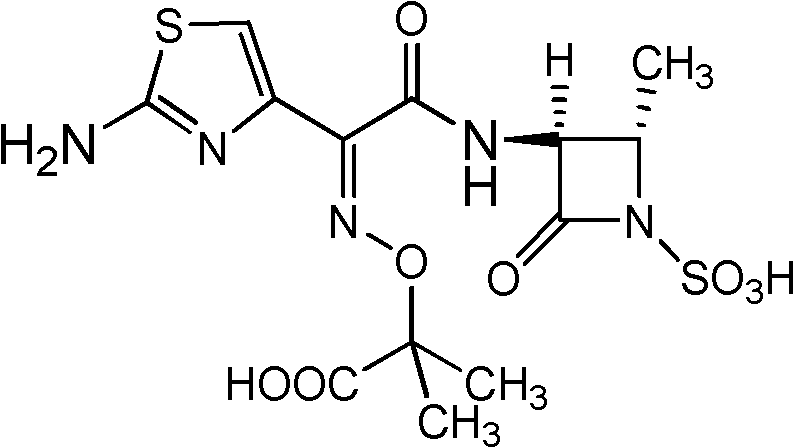

Method for preparing anhydrous beta-aztreonam

A technology of aztreonam and organic solvents, applied in the field of refining β-aztreonam and high-purity β-aztreonam, which can solve problems such as major technical defects or hidden quality problems, unfeasible production, unfavorable industrial production, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] 1) Add 500ml of absolute ethanol to a three-necked bottle, add 40g of α-aztreonam with a water content of 11%, stir, add 10ml of triethylamine at 25°C, add 4g of activated carbon after it is completely dissolved, and decolorize at room temperature for 30min. Filter and add the filtrate to a 1000ml crystallization tank;

[0027] 2) Take another 100ml round bottom flask, add 50ml of 30% ethanol anhydrous formic acid, add 0.5g of activated carbon, decolorize at room temperature for 30min, filter with a stainless steel sterilizing filter, add the mother liquor dropwise to the crystallization tank of step 1), and adjust the pH value 2.5, stirred to precipitate crystals, grown the crystals for 2 hours, filtered, washed with 100ml of acetone, and dried to obtain 31.5g of β-aztreonam fine product, with a yield of 78.75%, a water content of 1.2%, and a content of 98.8%.

Embodiment 2

[0029] 1) Add 500ml of absolute ethanol to a three-necked bottle, add 40g of α-aztreonam with a water content of 11%, stir, add 10ml of triethylamine at 25°C, add 4g of activated carbon after it is completely dissolved, and decolorize at room temperature for 30min. Filter and add the filtrate to a 1000ml crystallization tank;

[0030] 2) Take another 100ml round bottom flask, add 50ml of 30% anhydrous oxalic acid ethanol, add 0.5g of activated carbon, decolorize at room temperature for 30min, filter with a stainless steel sterilizing filter, add the mother liquor dropwise to the crystallization tank of step 1), adjust The pH value was 2, crystals were precipitated by stirring, grown for 2 hours, filtered, washed with 100ml of acetone, and dried to obtain 33.5g of β-aztreonam fine product, with a yield of 83.75%, a water content of 1.2%, and a content of 98.71%.

Embodiment 3

[0032]1) Add 500ml of absolute ethanol to a three-necked bottle, add 40g of α-aztreonam with a water content of 11%, stir, add 10ml of triethylamine at 25°C, add 4g of activated carbon after it is completely dissolved, and decolorize at room temperature for 30min. Filter, and add the filtrate to a 1000ml crystallization tank;

[0033] 2) Take another 100ml round bottom flask, add 50ml of 30% ethanol anhydrous benzoate, add 0.5g of activated carbon, decolorize at room temperature for 30min, filter with a stainless steel sterilizing filter, add the mother liquor dropwise to the crystallization tank of step 1), and adjust the pH When the value was 2, crystals were precipitated by stirring, grown for 2 hours, filtered, washed with 100ml of acetone, and dried to obtain 33.8g of β-aztreonam, with a yield of 84.5%, a water content of 1.12%, and a content of 98.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com