Method for recycling PET (polyethylene terephthalate) plastics, early-strength plastic mortar and method for preparing mortar

A plastic sand and plastic technology, which is applied in the field of plastic recycling and building materials, can solve the problems of large usage and difficult disposal, and achieve the effects of rapid strength growth, improvement of environmental pollution, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] The aggregate used in the present invention is sand and mineral powder, and the used sand is common river sand with a particle size below 9.5 mm. When sand is used, its gradation is designed according to the sand grain type AC-5 in the "Technical Specifications for Construction of Highway Asphalt Pavement". It is concluded that the following gradation ratio of aggregate can enhance the mechanical properties of mortar. The gradation requirement range of the aggregate of the present invention is shown in Table 1. For the aggregate materials smaller than 0.075mm, mineral powder is used instead.

[0042]

[0043] The present invention uses aggregates that are not the above-mentioned gradation to prepare mortar for experimental research. It is found that the prepared mortar has low strength in performance, which affects the application. See Table 2 for details.

[0044]

[0045] It can be seen from the above table that the compressive strength of the mortar prepared by...

Embodiment 2

[0051] Prepare early-strength plastic mortar, which is composed of: the sand and mineral powder graded in Table 4 above are used as aggregates, and PET chips are used as binders, wherein the mass ratio of aggregates to binders is 2.8:1. Its preparation method is as follows:

[0052] (1) Remove the labels and caps from waste PET plastic bottles to obtain relatively pure PET materials. After cutting the bottles into small PET fragments, wash them properly with clean water and dry them for later use;

[0053] (2) Weigh the aggregate and PET fragments according to the proportion, mix them, and then heat at 270-290°C for about 30-50 minutes to make the mixture flowable to obtain the road surface rapid repair mortar. The basic properties of the obtained mortar are shown in Table 5 shown.

[0054]

[0055] It can be seen from Table 5 that plastic mortar has a low water absorption rate and good anti-permeability performance, which has a certain effect on preventing road water dama...

Embodiment 3

[0057] The aggregates are graded according to the above table 4, and waste PET plastics are used as raw materials to prepare quick repair mortar. The mortar is composed of: the sand and mineral powder graded in the above table 4 are aggregates, and PET fragments are used as binders, wherein The mass ratio of aggregate to binder is 3:1. Its preparation method is as follows:

[0058] (1) Remove the labels and caps from waste PET plastic bottles to obtain relatively pure PET materials. After cutting the bottles into small PET fragments, wash them properly with clean water and dry them for later use;

[0059] (2) Weigh the aggregate and PET fragments according to the ratio, mix them, and then heat at 270°C. After about 50 minutes, the mixture becomes fluid to obtain the road surface rapid repair mortar. The basic properties of the obtained mortar are shown in Table 6.

[0060]

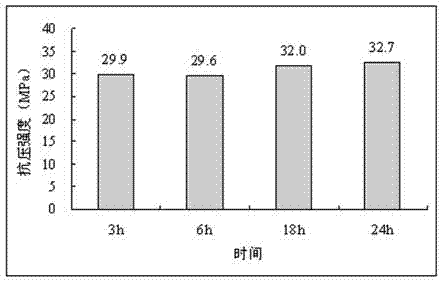

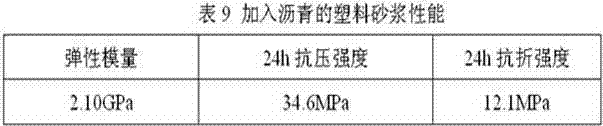

[0061] figure 1 Indicates the relationship between the compressive strength of plastic mortar and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com