Super-soft light wire cable with rated voltage of 250V and preparation technology thereof

A wire and cable, rated voltage technology, used in cable/conductor manufacturing, insulated cables, bendable cables, etc., can solve the problems of thick material extrusion, poor performance such as aging resistance, large laying space, etc., to improve flexibility. , High flexibility, the effect of reducing the laying space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

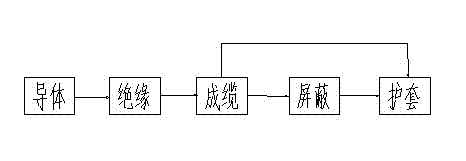

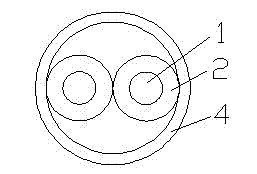

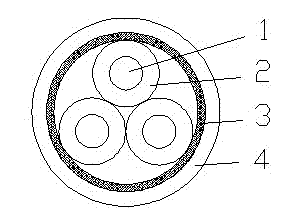

[0015] Control attached figure 1 , multi-strands of ultra-fine silver-plated copper wires are concentrically stranded with a wire and cable stranding machine to form a super-soft and lightweight wire and cable conductor. The diameter of the single wire is 0.051mm, which improves the flexibility of the cable; The distance ratio is 9 to 12 times) to ensure the overall flexibility of the conductor, and the silver-plated layer of the silver-plated conductor ensures electrical performance and transmission performance; the insulation layer is made of polyfluoroethylene propylene material extruded by a high-temperature extruder with thin walls, and the insulation is the best The thickness is 0.16mm, and the high temperature is up to 200℃. The insulated wire cores are twisted together by a cable forming machine; the thin-wall extruded polyfluoroethylene propylene material is used as the sheath layer; the insulation layer and the sheath layer are thin Wall type, withstand voltage 250V,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com