Rock wool sandwich composite board, and preparation method and application thereof

A sandwich composite panel and rock wool technology, applied in chemical instruments and methods, lamination, layered products, etc., can solve the problems of product thermal insulation effect, service life that cannot meet market demand, poor fire resistance, complex process, etc. The effect of long service life, enhanced earthquake resistance and high recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

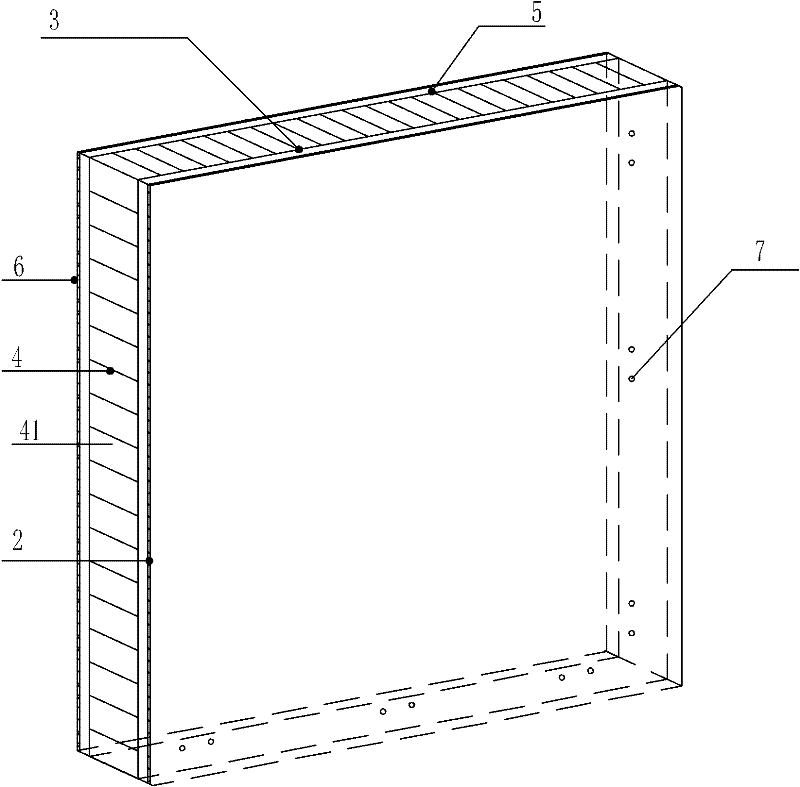

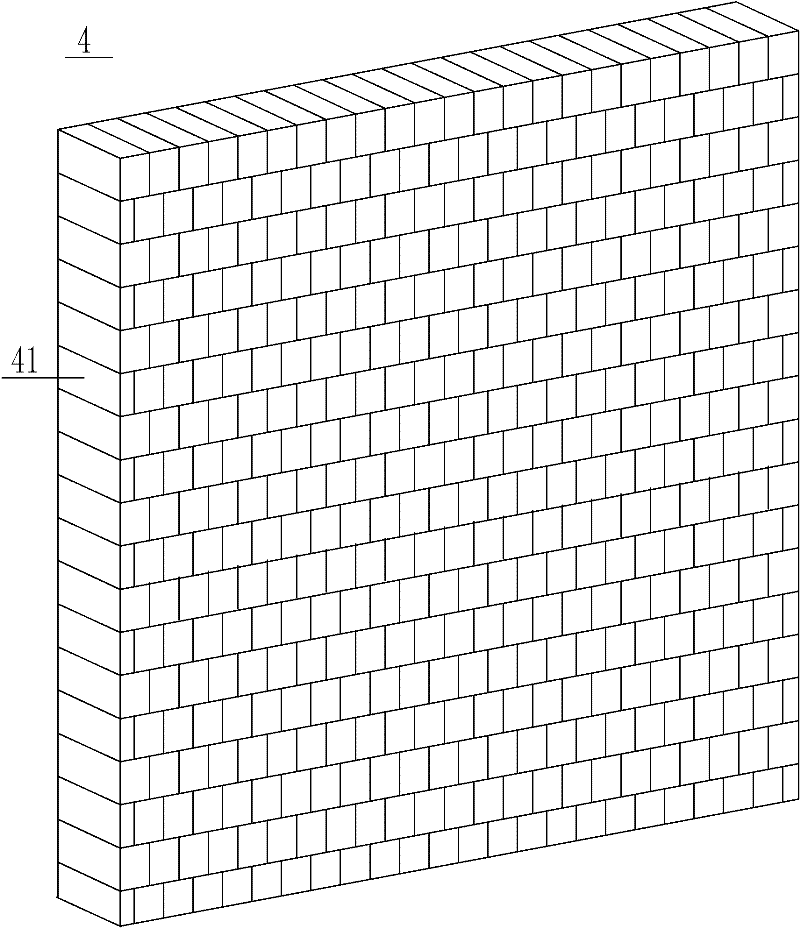

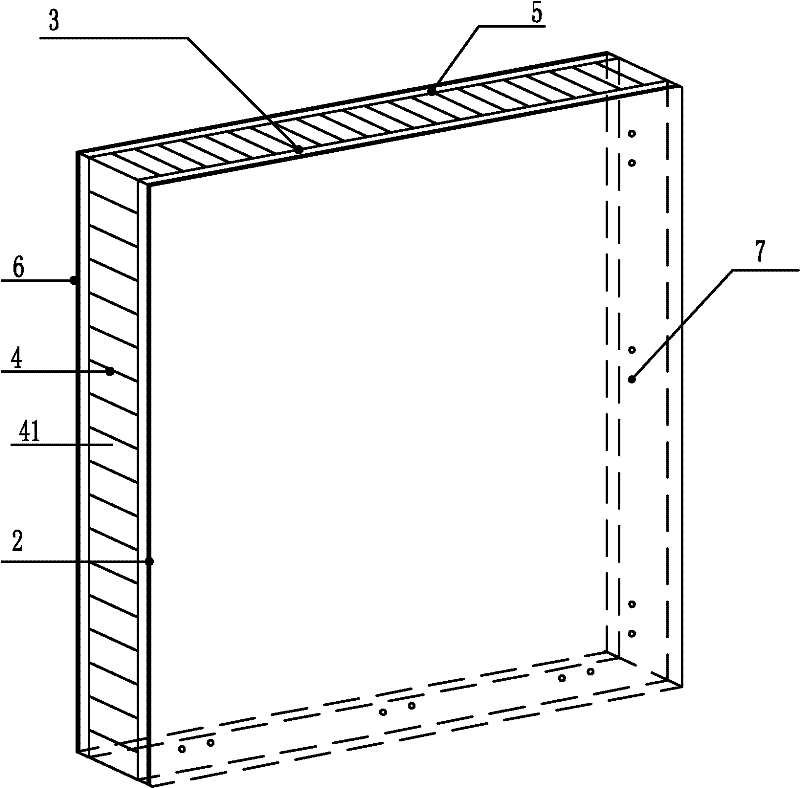

[0037] The surface layer 2 is an aluminum plate with a thickness of 0.3mm, a width of 800mm, and an unlimited length. The back layer 6 is an aluminum foil with an unlimited length, a thickness of 0.05mm, and a width of 700mm. 1.0m rock wool strips.

[0038] PU foaming materials include polyether, polyphenyl polymethylene isocyanate and other additives, other additives include: dimethylethanolamine, triethanolamine, dimethylaminoethyl ether, triethylenediamine, potassium isooctanoate , dimethylcyclohexylamine, silicone oil, triphosphate, dimethyl methyl phosphate, fluorodichloroethane, wherein the mass ratio of polyether and polyphenyl polymethylene isocyanate is 1:1.1, polyether The mass ratio with other additives is 1:0.001.

[0039] After the aluminum plate is degreased and oxidized, put it into the line decoiler and introduce it into the laminating machine mouth, put the degreased aluminum foil into the upper bracket, introduce it into the laminating machine mouth, and spr...

Embodiment 2

[0041] The surface layer 2 is an aluminum alloy plate with a thickness of 2.0mm, a width of 1500mm, and an unlimited length. The back layer 6 is an aluminum foil with an unlimited length, a thickness of 0.08mm, and a width of 1450mm. Rock wool strips with a length of 1.2m.

[0042] PU foaming materials include polyether, polyphenyl polymethylene isocyanate and other additives, other additives include: dimethylethanolamine, triethanolamine, dimethylaminoethyl ether, triethylenediamine, potassium isooctanoate , dimethylcyclohexylamine, silicone oil, triphosphate, dimethyl methyl phosphate and fluorodichloroethane, wherein the mass ratio of polyether to polyphenyl polymethylene isocyanate is 1:1.3, polyether The mass ratio with other additives is 1:0.1.

[0043]The aluminum alloy plate and aluminum foil are degreased and sandblasted, trimmed before being introduced into the laminating machine mouth, and after entering the laminating machine mouth, the prepared PU foam material i...

Embodiment 3

[0045] The surface layer 2 is an aluminum-magnesium-manganese alloy plate with a thickness of 1.5mm, a width of 1500mm, and an unlimited length. The back layer 6 is a color steel plate with an unlimited length, a thickness of 0.5mm, and a width of 1450mm. 100mm, 1.5m long rock wool strips.

[0046] The formula of PU foam material is basically the same as that of Example 2, except that the mass ratio of polyether and polyphenyl polymethylene isocyanate is 1: 1.4, and the mass ratio of polyether and other additives is 1: 0.2 .

[0047] The aluminum-magnesium-manganese alloy plate and color steel plate are degreased and sprayed, and trimmed before being introduced into the laminating machine mouth, and automatically returned to the edge and closed under the drive of the assembly line. After entering the laminating machine mouth, the prepared The PU foam material is sprayed on the inner side of the aluminum-magnesium-manganese alloy plate and the color steel plate, and the rock w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com