Method for removing residual catalyst in bisphenol A reaction liquid

A technology of reaction solution and catalyst, applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve problems such as removal, and achieve the effect of simple regeneration operation, simple process flow and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

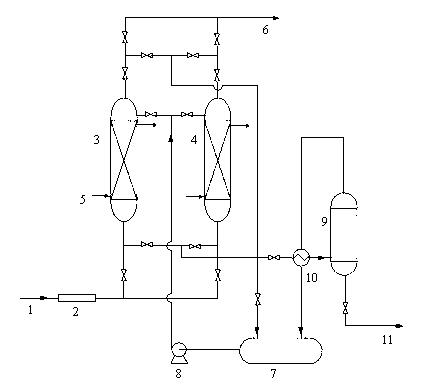

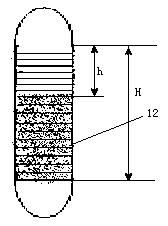

Method used

Image

Examples

Embodiment 1

[0013] Example 1: The bisphenol A reaction solution is added to the adsorber device filled with fiber mold coalescing material, the temperature is controlled at 75°C, normal pressure, and the volume space velocity is 25m 3 / h, this device can continuously process the amount of bisphenol A reaction solution that is 35 times the volume of the packing, when the processed bisphenol A does not meet the acidity requirements, the packing of the device needs to be regenerated, and the packing of the device is washed with hot acetone (the amount is the processed The amount of bisphenol A reaction solution is 2 / 3, of which fresh acetone and recovered acetone account for 50% respectively), and the volume space velocity of acetone is 80m 3 / h, the regeneration temperature is 55°C, and the regenerated device packing can return to the original processing capacity.

Embodiment 2

[0014] Example 2: The bisphenol A reaction liquid is added to the adsorber device filled with fiber mold coalescing material, the temperature is controlled at 75°C, normal pressure, and the volume space velocity is 25 m 3 / h, this device can continuously process the amount of bisphenol A reaction solution that is 35 times the volume of the packing, when the processed bisphenol A does not meet the acidity requirements, the packing of the device needs to be regenerated, and the packing of the device is washed with hot acetone (the amount is the processed The amount of bisphenol A reaction solution is 1 / 3, wherein the ratio of fresh acetone to recovered acetone is 3:7), and the volumetric space velocity of acetone is 85 m 3 / h, the regeneration temperature is 50°C, and the regenerated device packing can recover to the original processing capacity.

Embodiment 3

[0015] Example 3: Add the bisphenol A reaction liquid to the adsorption device filled with fiber mold coalescing material, the temperature is controlled at 75°C, normal pressure, and the volume space velocity is 25 m 3 / h, this device can continuously process the amount of bisphenol A reaction solution that is 35 times the volume of the packing, when the processed bisphenol A does not meet the acidity requirements, the packing of the device needs to be regenerated, and the packing of the device is washed with hot acetone (the amount is the processed The amount of bisphenol A reaction solution is 1 / 3, wherein the ratio of fresh acetone to recovered acetone is 1:1), and the volumetric space velocity of acetone is 90 m 3 / h, the regeneration temperature is 45°C, and the regenerated device packing can recover to the original processing capacity.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bronsted acidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com