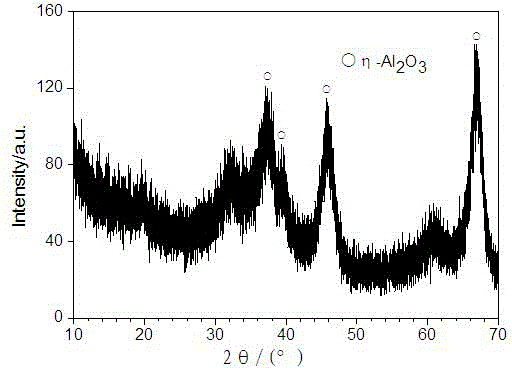

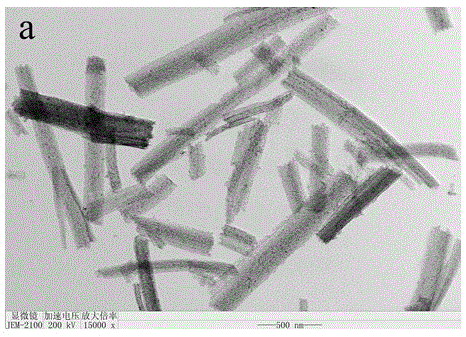

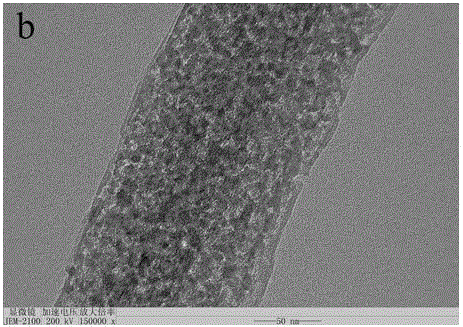

Preparation method of silver-based eta-Al2O3 mesoporous fiber antibacterial powder

A technology of antibacterial powder and fiber, applied in botany equipment and methods, chemicals for biological control, animal repellent, etc., can solve problems that have not been reported, and achieve improved glaze layer performance, high sintering activity, The effect of a large surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] A silver-based η-Al 2 o 3 The preparation method of mesoporous fiber antibacterial powder comprises the following steps:

[0023] 1) Dissolve PEG600 in deionized water at a weight ratio of 1:5 to obtain a transparent solution A, and then take Al(NO 3 ) 3 9H 2 O was added to solution A, and solution B was obtained after complete dissolution;

[0024] 2) Take CO(NH at a weight ratio of 5:17 2 ) 2 Add solution B to obtain solution C after completely dissolving, and transfer solution C to the reaction kettle to obtain reaction product D through hydrothermal reaction; the conditions of hydrothermal reaction are: the filling degree of the reaction kettle is 70-80%, and the reaction The temperature is 100-140°C.

[0025] 3) Take out the reaction product D in the reaction kettle and cool it down to room temperature naturally, then obtain the product E by suction filtration, wash the product E with deionized water and absolute ethanol respectively, dry it, and grind i...

Embodiment 1

[0029]A silver-based η-Al 2 o 3 The preparation method of mesoporous fiber antibacterial powder comprises the following steps:

[0030] 1) Dissolve PEG600 (10g) in deionized water (50ml) at a weight ratio of 1:5 to obtain a transparent solution A, and then take Al(NO 3 ) 3 9H 2 O (8g) was added to solution A, and solution B was obtained after complete dissolution;

[0031] 2) Take CO(NH at a weight ratio of 5:17 2 ) 2 (20g) was added into solution B, and solution C was obtained after completely dissolving, and solution C was transferred to the reactor, and reaction product D was obtained through hydrothermal reaction; the conditions of hydrothermal reaction were: the filling degree of the reactor was 70%, The reaction temperature is 100°C.

[0032] 3) Take out the reaction product D in the reaction kettle and cool it down to room temperature naturally, then obtain the suction filtration product E through suction filtration, wash the product E with deionized wate...

Embodiment 2

[0041] A silver-based η-Al 2 o 3 The preparation method of mesoporous fiber antibacterial powder comprises the following steps:

[0042] 1) Dissolve PEG600 (10g) in deionized water (50ml) at a weight ratio of 1:5 to obtain a transparent solution A, and then take Al(NO 3 ) 3 9H 2 O (8g) was added to solution A, and solution B was obtained after complete dissolution;

[0043] 2) Take CO(NH at a weight ratio of 5:17 2 ) 2 (20g) was added into solution B, and solution C was obtained after completely dissolving, and solution C was transferred to the reactor, and reaction product D was obtained through hydrothermal reaction; the conditions of hydrothermal reaction were: the filling degree of the reactor was 80%, The reaction temperature was 140°C.

[0044] 3) Take out the reaction product D in the reaction kettle and cool it down to room temperature naturally, then obtain the suction filtration product E through suction filtration, wash the product E with deionize...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com