Explosion-proof wheel assembly

An assembly and wheel technology, applied in the field of explosion-proof wheel assembly, can solve the problems of reduced vehicle comfort and reliability, affecting vehicle structure and performance, increasing wheel manufacturing and use costs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] Below in conjunction with example the present invention is described in detail.

[0043] The present invention is a safe wheel assembly for high-speed and long-distance driving. It is based on standard tubeless tires and standard rims. Special rims can also be selected, including new lightweight rims such as aluminum alloy rims.

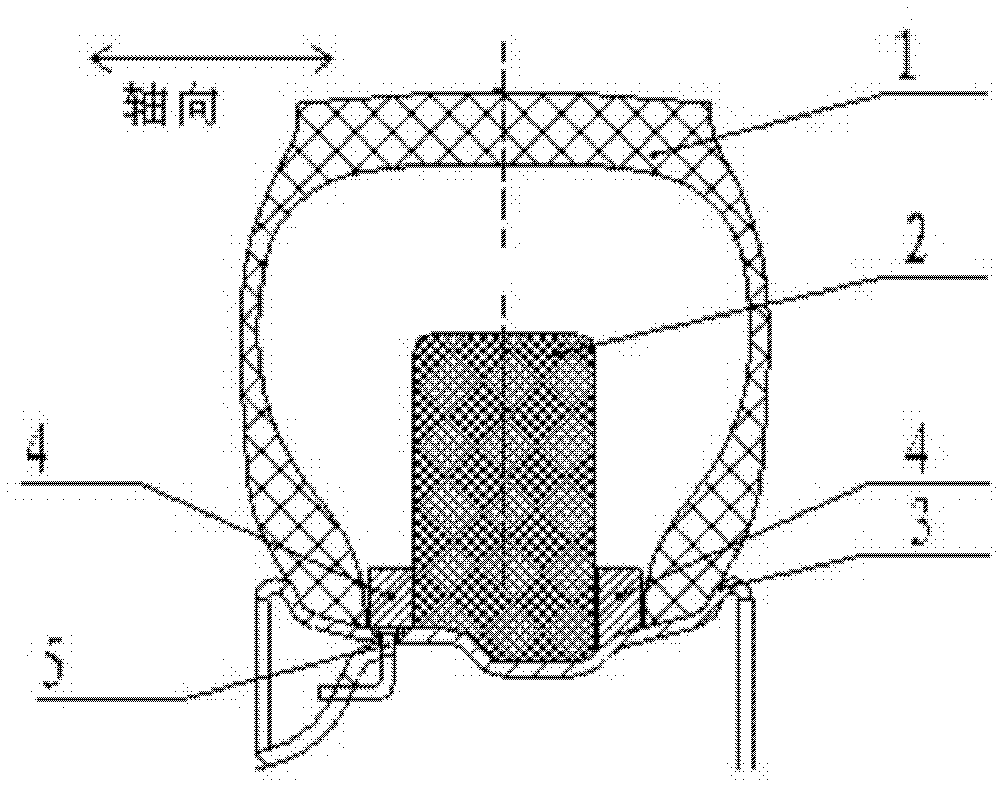

[0044] The wheel assembly of the present invention comprises a standard tubeless tire 1, a metal rim 3 and a hard wheel support body 2. A hard wheel support body 2 is installed between the standard tubeless tire 1 and the metal rim 3, and high-temperature grease is applied between the hard wheel support body 2 and the rim 3, so that the safety wheel supports the body 2 when it continues running with zero pressure. It can slide between the rim and the rim 3, and the hard wheel support body 2 can be made of non-metallic material or metallic material.

[0045] Such as figure 1 The cross-sectional view of Example 1 of the explosion-proof vehicle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com