Numerically-controlled foam block cutting all-in-one machine

An all-in-one machine and foam block technology, which is applied in metal processing and other directions, can solve the problems of low processing precision, need more equipment, and tediousness, etc., and achieve the effect of improving processing accuracy and production efficiency, reducing labor intensity and labor force, and compact and reasonable structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

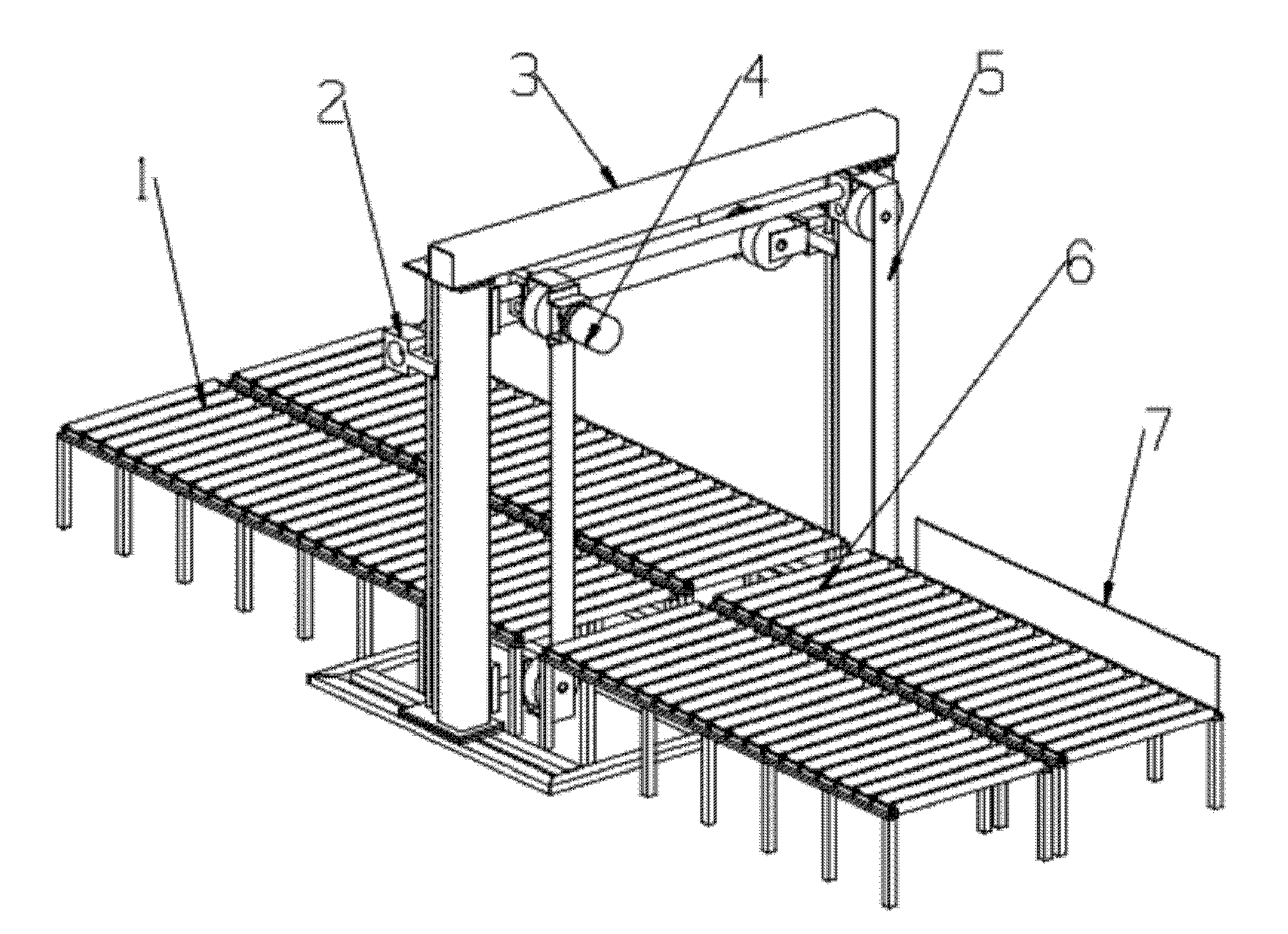

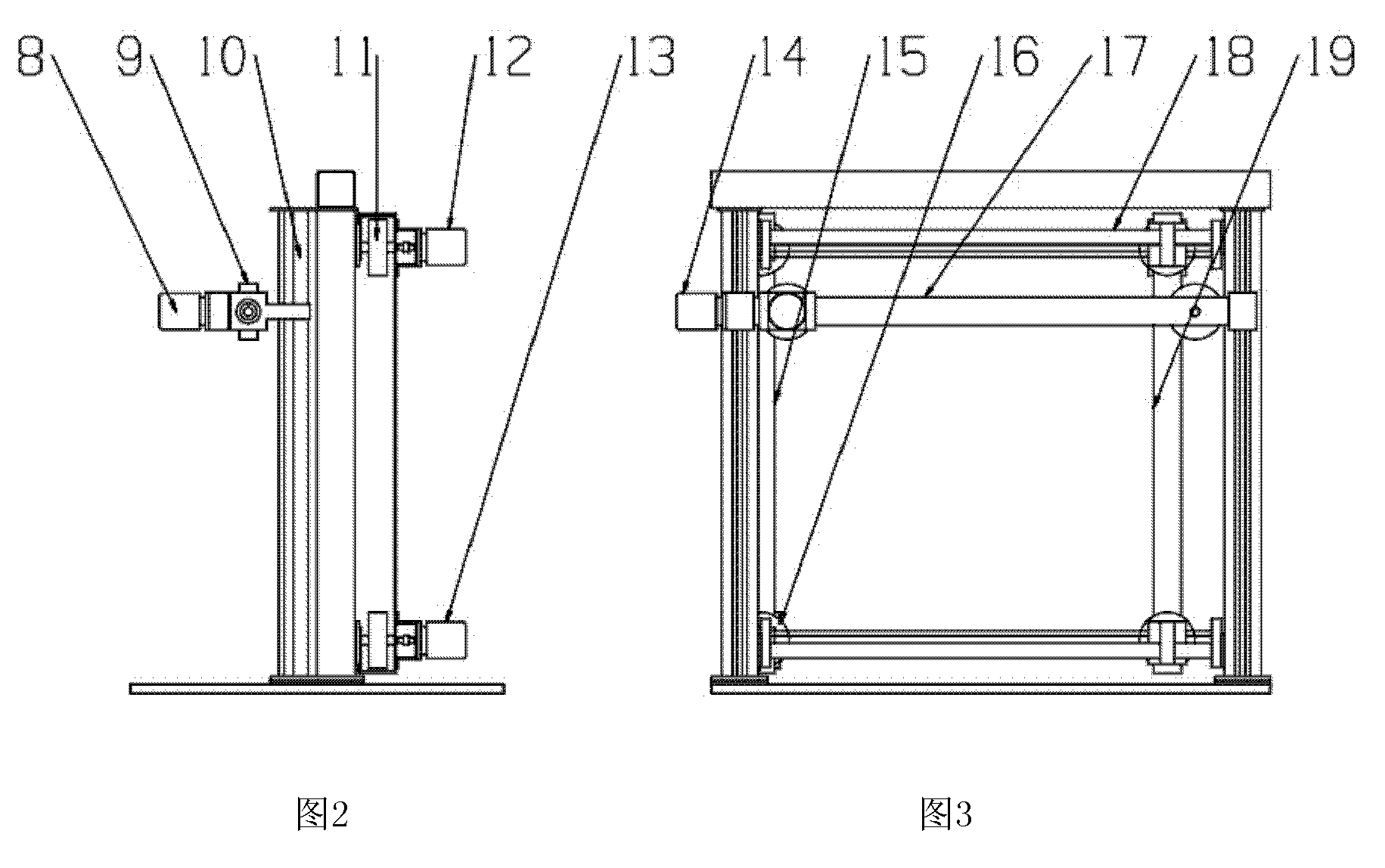

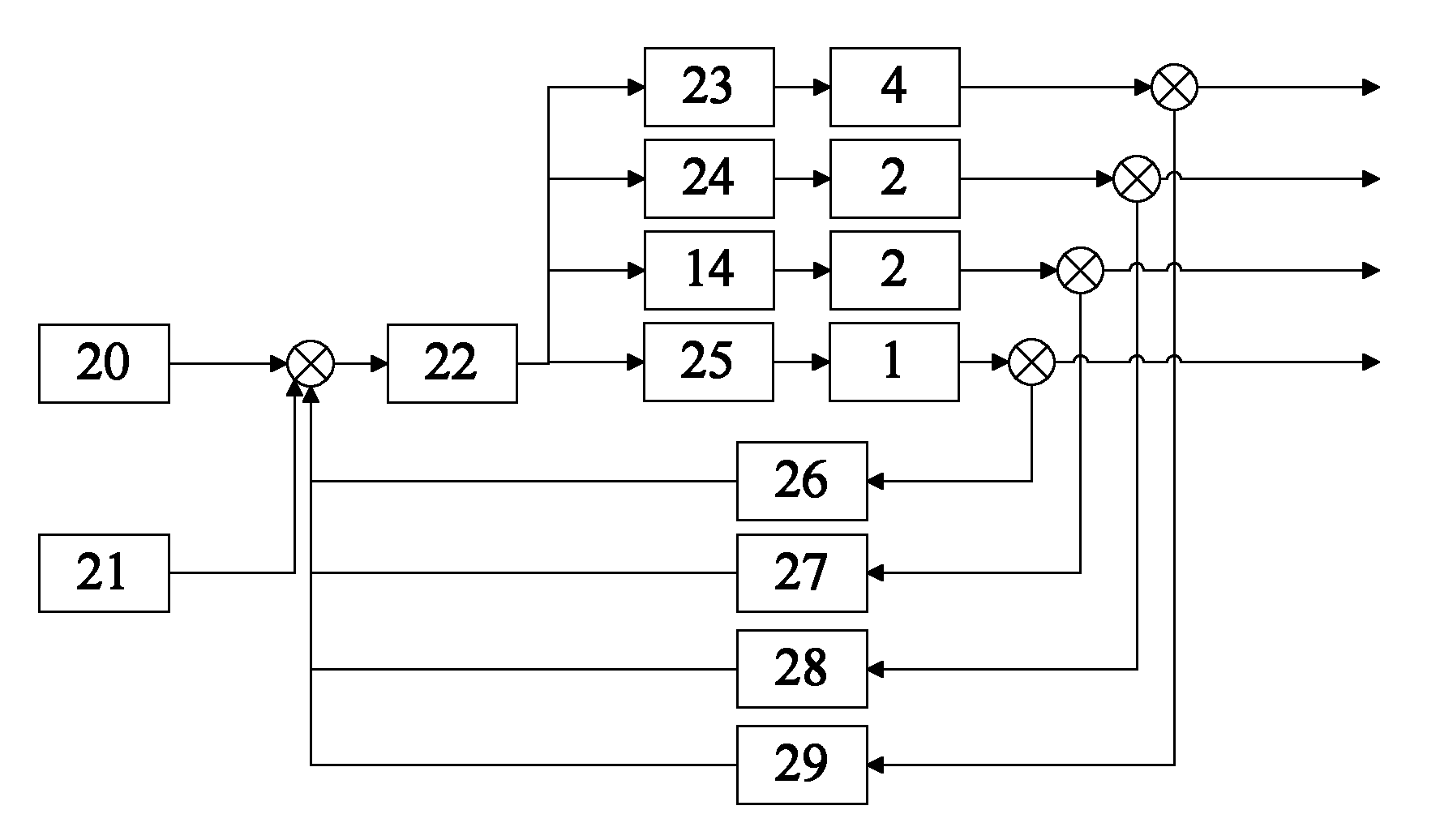

[0018] Such as figure 1 , figure 2 and image 3 As shown, the CNC foam block cutting integrated machine of the present invention includes a working platform 1, a gantry tower 3, a top and front and rear cutting device 2, a left side cutting device 4 and a right side cutting device 5. In the following narrative, the figure 1 The direction to the left of is forward. The gantry tower 3 spans the left and right sides of the working platform 1. The working platform 1 passes through the gantry tower 3 and is set on the ground. The right side of the working platform 1 is provided with a positioning device 7. The positioning device 7 is adjusted and fixed on the On the working platform 1, it is used for positioning the foam block during cutting. The foam block is clamped on the working platform 1 to perform positioning in the left and right direction through the positioning device 7, that is, positioning perpendicular to the moving direction of the workpiece. The positioning devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com