cutting tool

A cutting tool and cutting head technology, which is applied in thread cutting tools, manufacturing tools, drilling accessories, etc., can solve the problems of cutting tool rigidity reduction, cutting head vibration, thread tooth defect, etc., to reduce vibration and reduce replacement frequency , Reduce the effect of thread tooth defect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

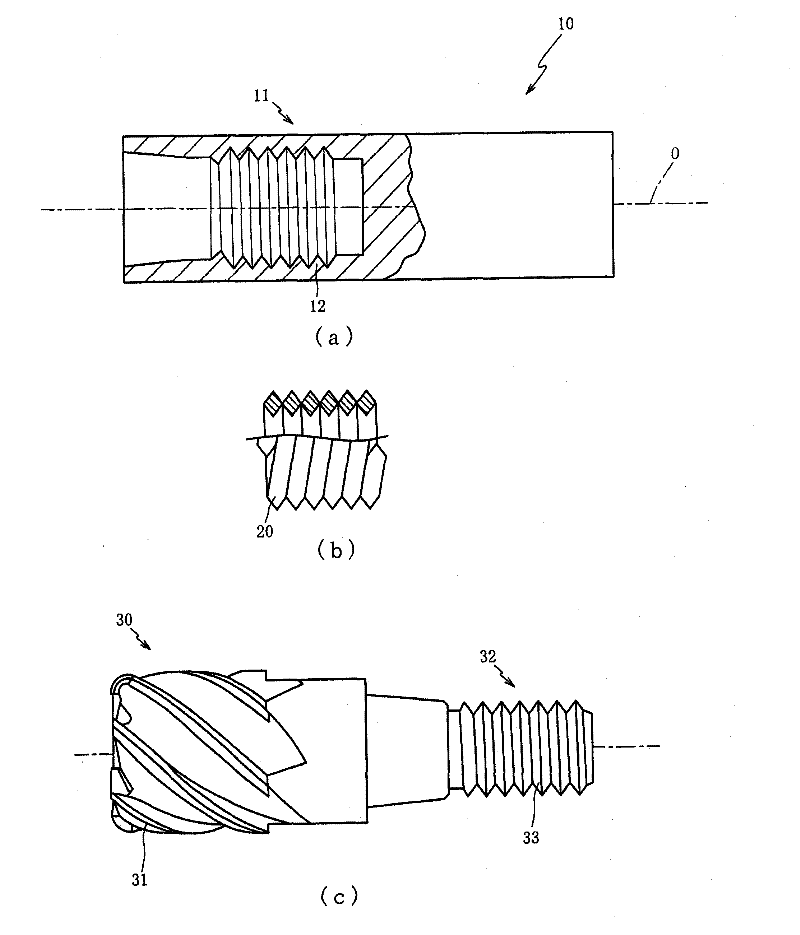

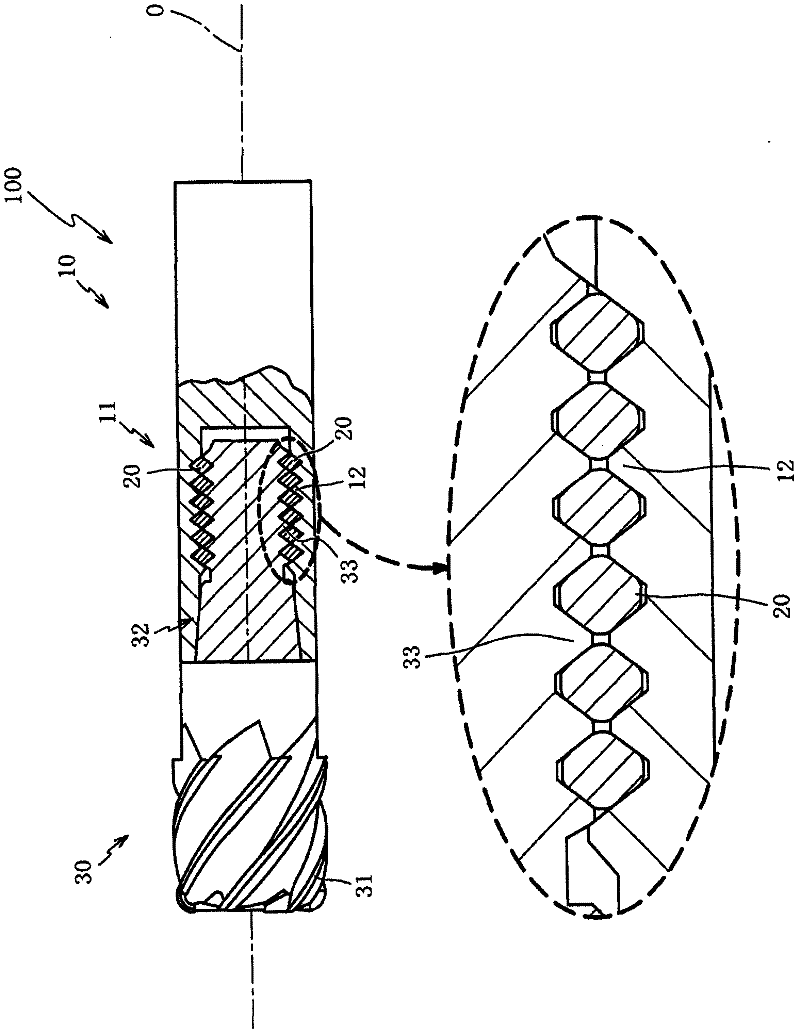

[0024] The preferred embodiments of the present invention are described below in conjunction with the accompanying drawings. combine first figure 1 The structure of each part of the cutting tool 100 in one embodiment of the present invention will be described. figure 1 (a) is a side view of the main body 10 constituting the cutting tool 100 according to an embodiment of the present invention, figure 1 (b) is a side view of the high-precision screw lining 20, figure 1 (c) is a side view of the cutting head 30 . in, figure 1 (a) shows the female thread part 11 of the main body part 10 in a cross-sectional manner, figure 1 (b) schematically shows the high-precision threaded bushing for simplicity, and at the same time shows a part of the high-precision threaded bushing 20 in a cross-sectional manner ( figure 1 (b) upper side).

[0025] Such as figure 1 As shown in (a), the main body portion 10 is made of a cemented carbide formed by press-sintering tungsten carbide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com