A method for encapsulating an optoelectronic device

An optoelectronic device and packaging method technology, applied in the field of optoelectronics, can solve the problems of black spot formation, device performance degradation, stability degradation, etc., and achieve the effects of prolonging device life, improving device stability, and simplifying process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

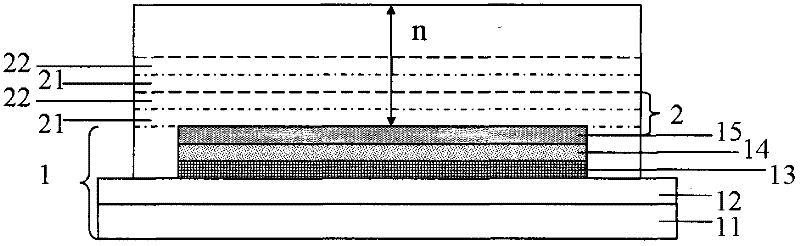

[0028] like figure 1 As shown, 1 is an organic electroluminescent device, the anode layer 12 is ITO, and the hole transport layer 13 is N, N'-bis(naphthylidene-1-yl)-N,N'-bis(phenyl) - benzidine (NPB), electron transport layer 14 is 1,3,5-(tri-N-phenyl-2-benzimidazole-2) benzene 41 (TPBi), cathode layer 15 is Mg:Ag alloy, inorganic thin film Packaging material layer 21 is Al 2 o 3 , UV-curable resin 22 includes 55% epoxidized octadecyl-conjugated triene-9,11,13-acid triglyceride, 4% glycerol, 0.98% lead oxide, 5% toluene di Isocyanate, 8% trimethylol propane, 0.01% hydroquinone, 12% tetrahydrofuran, 6% 2-hydroxyethyl methacrylate, 0.01% dibutyltin dilaurate, 1% 2, 2-dimethoxy-phenyl ketone and 8% trimethylol propane triacrylate, the number of cycles n is 20, the device structure is:

[0029] Glass substrate / ITO / NPB(50nm) / TPBi(30nm) / Mg:Ag(200nm) / [Al 2 o 3 (200nm) / UV curable resin (100nm)] 20

[0030] The preparation method is as follows:

[0031] ①Use detergent, aceton...

Embodiment 2

[0039] like figure 1 As shown, 1 is an organic electroluminescent device, the anode layer 12 is ITO, and the hole transport layer 13 is N, N'-bis(naphthylidene-1-yl)-N,N'-bis(phenyl) - benzidine (NPB), electron transport layer 14 is 1,3,5-(tri-N-phenyl-2-benzimidazole-2) benzene 41 (TPBi), cathode layer 15 is Mg:Ag alloy, inorganic thin film Packaging material layer 21 is Al 2 o 3, UV-curable resin 22 includes 55% epoxidized octadecyl-conjugated triene-9,11,13-acid triglyceride, 4% glycerol, 0.01% lead oxide, 5% toluene di Isocyanate, 8% trimethylol propane, 0.989% hydroquinone, 12% tetrahydrofuran, 6% 2-hydroxyethyl methacrylate, 0.01% dibutyltin dilaurate, 1% 2, 2-dimethoxy-phenyl ketone and 8% trimethylol propane triacrylate, the number of cycles n is 16, the device structure is:

[0040] Glass substrate / ITO / NPB(50nm) / TPBi(30nm) / Mg:Ag(200nm) / [Al 2 o 3 (200nm) / UV curable resin (100nm)] 16

[0041] The preparation method is similar to Example 1.

Embodiment 3

[0043] like figure 1 As shown, 1 is an organic electroluminescent device, the anode layer 12 is ITO, and the hole transport layer 13 is N, N'-bis(naphthylidene-1-yl)-N,N'-bis(phenyl) - benzidine (NPB), electron transport layer 14 is 1,3,5-(tri-N-phenyl-2-benzimidazole-2) benzene 41 (TPBi), cathode layer 15 is Mg:Ag alloy, inorganic thin film Packaging material layer 21 is Al 2 o 3 , UV-curable resin 22 includes 30% epoxidized octadecaconjugated triene-9,11,13-acid triglyceride, 5% glycerol, 1% lead oxide, 7% toluene di Isocyanate, 10% trimethylol propane, 1% hydroquinone, 15% tetrahydrofuran, 10% 2-hydroxyethyl methacrylate, 1% dibutyltin dilaurate, 8% 2, 2-dimethoxy-phenyl ketone and 12% trimethylol propane triacrylate, the number of cycles n is 12, the device structure is:

[0044] Glass substrate / ITO / NPB(50nm) / TPBi(30nm) / Mg:Ag(200nm) / [Al 2 o 3 (200nm) / UV curable resin (100nm)] 12

[0045] The preparation method is similar to Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com