Bacillus licheniformis and its method for preparing rennet freeze-dried powder

A technology of Bacillus licheniformis and chymosin, applied in the field of bioengineering, can solve the problems of low commodity value and low yield of finished products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

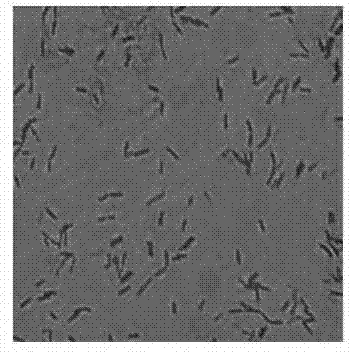

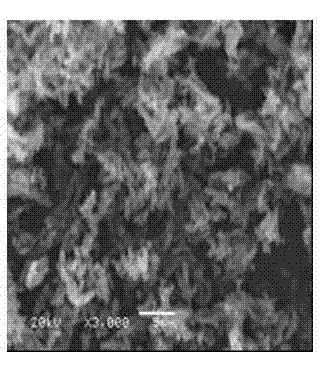

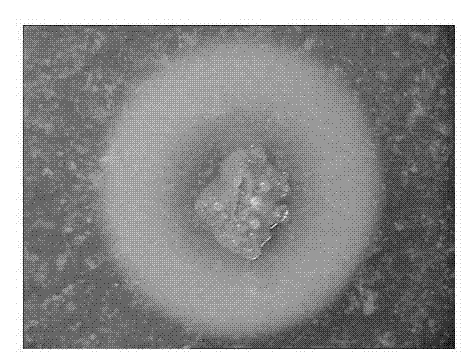

Image

Examples

Embodiment 1

[0069] The bran was added to 100 mL of tap water for every 10 g of bran, and then boiled for 10 min. After filtering, tap water was used to make up the original volume to obtain bran juice. The obtained bran was divided into 500mL Erlenmeyer flasks, sterilized at 115°C for 20min, and cooled to 30°C at room temperature as a liquid fermentation medium.

[0070] Bacillus licheniformis D3.11 was inoculated in the liquid fermentation medium, and cultured on a shaker at 37 °C and 140 r / min for 24 hours to obtain seed liquid. Add the seed liquid into the liquid fermentation medium according to the inoculum amount of 3%, and vibrate at 37°C and 200r / min for 72 hours to obtain the fermentation liquid. The fermented liquid was centrifuged at 4°C and 8000 r / min for 10 min to obtain a supernatant, and the curdling activity was measured to be 324.5 SU / mL.

[0071] Dry and grind the ammonium sulfate, slowly add ammonium sulfate powder to the supernatant until its saturation reaches 30%, le...

Embodiment 2

[0074] The bran was added to 100 mL of tap water for every 10 g of bran, and then boiled for 10 min. After filtering, tap water was used to make up the original volume to obtain bran juice. The obtained bran was divided into 500mL Erlenmeyer flasks, sterilized at 115°C for 20min, and cooled to 30°C at room temperature as a liquid fermentation medium.

[0075] Bacillus licheniformis D3.11 was inoculated in the liquid fermentation medium, and cultured on a shaker at 37 °C and 140 r / min for 24 hours to obtain seed liquid. The seed solution was added into the liquid fermentation medium according to the inoculum amount of 3%, and cultured with shaking at 37°C and 220r / min for 72 hours to obtain a fermentation solution. The fermented liquid was centrifuged at 4°C and 8000 r / min for 10 min to obtain a supernatant, and the curdling activity was measured to be 333.5 SU / mL.

[0076] Dry and grind the ammonium sulfate, slowly add ammonium sulfate powder to the supernatant until its satu...

Embodiment 3

[0079] The bran was added to 100 mL of tap water for every 10 g of bran, and then boiled for 10 min. After filtering, tap water was used to make up the original volume to obtain bran juice. The obtained bran was divided into 500mL Erlenmeyer flasks, sterilized at 115°C for 20min, and cooled to 30°C at room temperature as a liquid fermentation medium.

[0080] Bacillus licheniformis D3.11 was inoculated in the liquid fermentation medium, and cultured on a shaker at 37 °C and 140 r / min for 24 hours to obtain seed liquid. The seed solution was added into the liquid fermentation medium according to the inoculum amount of 3%, and cultured with shaking at 37°C and 240r / min for 72 hours to obtain a fermentation solution. The fermented liquid was centrifuged at 4°C and 8000 r / min for 10 min to obtain a supernatant, and the curdling activity was measured to be 343.5 SU / mL.

[0081] Dry and grind the ammonium sulfate, slowly add ammonium sulfate powder to the supernatant until its satu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com