A kind of cleaning solution for flat panel display and preparation method thereof

A flat-panel display and cleaning liquid technology, applied in the direction of chemical instruments and methods, detergent compounding agents, detergent compositions, etc., can solve environmental pollution and other problems, and achieve the effect of strong cleaning ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

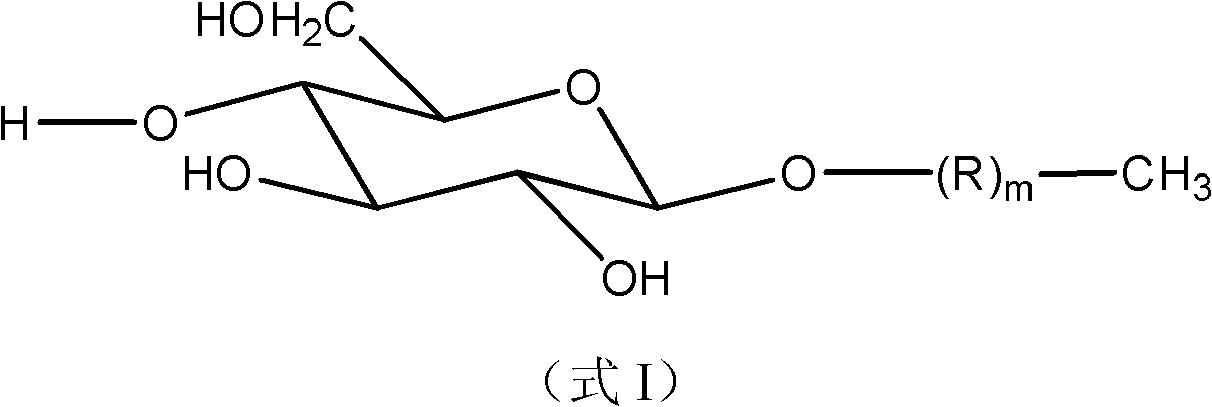

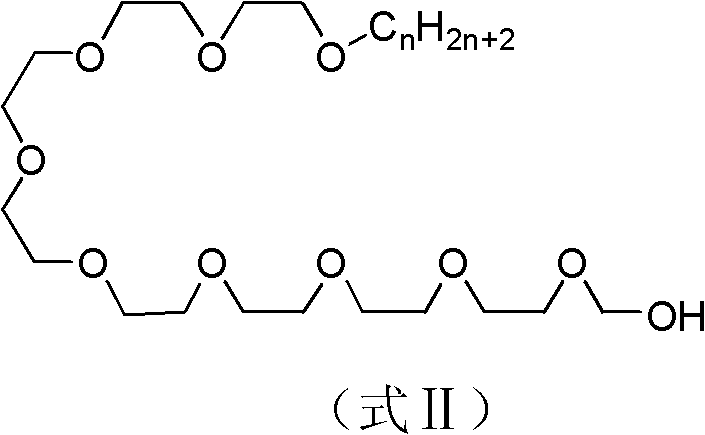

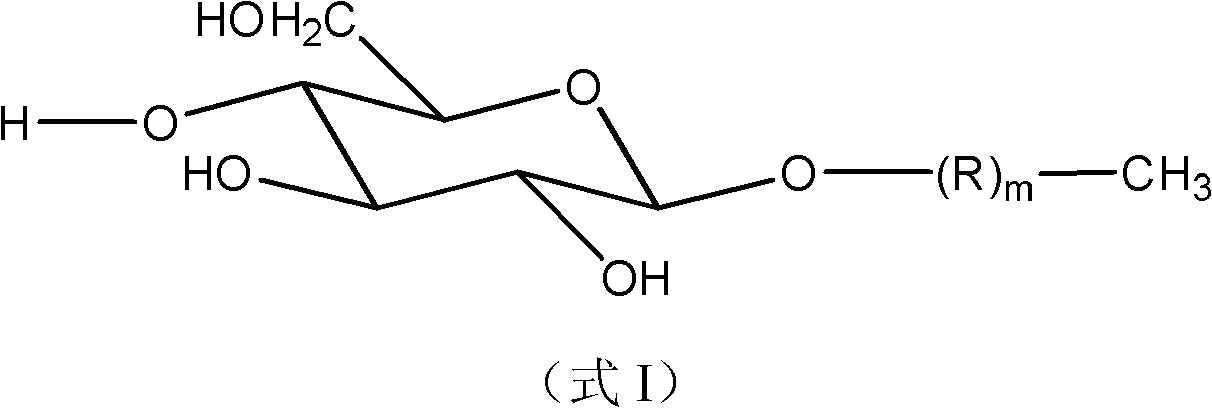

[0021] The components in the following percentages by weight are stirred evenly at room temperature to obtain the cleaning solution provided by the invention: surfactant compound APG0810 shown in formula I 5%, organic solvent diethylene glycol monomethyl ether 10%, chelating agent EDTA 1% 1%, antiseptic sorbitol 1%, n is the defoamer monododecyl nonaethylene glycol ether (trade name laureth-9) 0.1% and deionized water 82.9% shown in the formula II of 12; The resistivity of deionized water is 20 megohms, and the total metal ion concentration is 50ug / L.

[0022] Add the above cleaning solution into an ultrasonic cleaning machine, raise the temperature to 50°C, put the TFT panel in the cleaning solution, turn on the ultrasonic wave, and clean for 3 minutes. Next, the cleaned glass panel was washed in deionized water at 50° C. for 3 minutes under the same cleaning conditions, and then dried in an oven.

[0023] Using a scanning electron microscope (SME) (Hitachi, S-4700) to magni...

Embodiment 2

[0025] Stir the components in the following percentages by weight evenly at room temperature to obtain the cleaning solution provided by the invention: surfactant compound APG0810 shown in formula I 10%, organic solvent butyl carbitol 15%, chelating agent EDTA 0.5% , preservative benzotriazole 1.5%, n is the antifoaming agent monododecyl nonaethylene glycol ether (trade name laureth-9) shown in the formula II of 12 0.1%, deionized water 72.9%; The deionized water has a resistivity of 20 megohms and a total metal ion concentration of 50 ug / L.

[0026] Add the above-mentioned cleaning solution into the cleaning tank, raise the temperature to 50° C., put the etched glass panel (Al—Si—Cu wiring) into it, soak it for 30 minutes, and let it stand still. Next, the cleaned glass panel was immersed in 25° C. deionized water for 3 minutes, and then the panel was taken out, and the same operation was repeated. Dry with a stream of nitrogen.

[0027] Using a scanning electron microscope...

Embodiment 3

[0029] Stir the components in the following percentages by weight evenly at room temperature to obtain the cleaning solution provided by the invention: 20% of surfactant compound APG0814 shown in formula I, 30% of organic solvent diglyme, chelating agent diethylene glycol dimethyl ether Ethyltriaminepentaacetic acid 5%, preservative sorbitol 5%, n is the defoamer monododecyl nonaglycol ether (trade name laureth-9) shown in formula II of 12 5% , 35% deionized water; the resistivity of the deionized water is 25 megohm, and the total metal ion concentration is 50ug / L.

[0030] Add the above-mentioned cleaning solution into the cleaning tank, raise the temperature to 50° C., put the etched glass panel (Al—Si—Cu wiring) into it, soak it for 30 minutes, and let it stand still. Next, the cleaned glass panel was immersed in 25° C. deionized water for 3 minutes, and then the panel was taken out, and the same operation was repeated. Dry with a stream of nitrogen.

[0031] Using a scan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com