A device and method for removing hardness in drinking water

A technology for drinking water and hardness, applied in descaling and water softening, chemical instruments and methods, adsorption water/sewage treatment, etc. Low, easy-to-operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Install the DOSATRON hydraulic proportional dosing device on the tap water pipeline, fully mix the tap water and ferric chloride in the dosing device, and the dosing concentration of ferric chloride is 8mg / L. The mixed tap water flows through the quartz sand filter column, wooden activated carbon filter column and ultrafiltration membrane sequentially from the water outlet of the hydraulic proportional dosing device. The average pore diameter of the quartz sand filter column is 0.4 μm, the average pore diameter of the wooden activated carbon filter column is 0.1 μm, and the ultrafiltration membrane is an internal pressure ultrafiltration membrane.

Embodiment 2

[0025] Install the DOSATRON hydraulic proportional dosing device on the tap water pipeline, fully mix the tap water and ferric chloride in the dosing device, and the dosing concentration of ferric chloride is 5mg / L. The mixed tap water flows through the quartz sand filter column, wooden activated carbon filter column and ultrafiltration membrane sequentially from the water outlet of the hydraulic proportional dosing device. The average pore size of the quartz sand filter column is 0.2 μm, the average pore size of the wooden activated carbon filter column is 0.2 μm, and the ultrafiltration membrane is an internal pressure ultrafiltration membrane.

Embodiment 3

[0027] Install the DOSATRON hydraulic proportional dosing device on the tap water pipeline, fully mix the tap water and ferric chloride in the dosing device, and the dosing concentration of ferric chloride is 10mg / L. The mixed tap water flows through the quartz sand filter column, wooden activated carbon filter column and ultrafiltration membrane sequentially from the water outlet of the hydraulic proportional dosing device. The average pore size of the quartz sand filter column is 0.1 μm, the average pore size of the wooden activated carbon filter column is 0.3 μm, and the ultrafiltration membrane is an internal pressure ultrafiltration membrane.

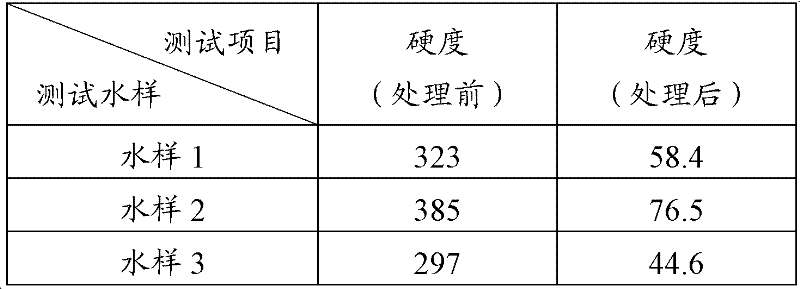

[0028] Experiments were carried out with high-hardness water in different areas of Beijing. The original tap water and the tap water passed through the dosing device and the water purifier equipped with a filter membrane or activated carbon filter element were sampled to test the hardness of the water. The results are shown in

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore size | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap