A squeeze roller for lead ingot cold granulator

A technology of cold granulator and extrusion roller, applied in the field of extrusion roller, which can solve the problems of long processing cycle, high difficulty, unfavorable maintenance and replacement of the roller body, etc., and achieve processing difficulty and cycle reduction, processing cycle and cost reduction , Conducive to the effect of maintenance and replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

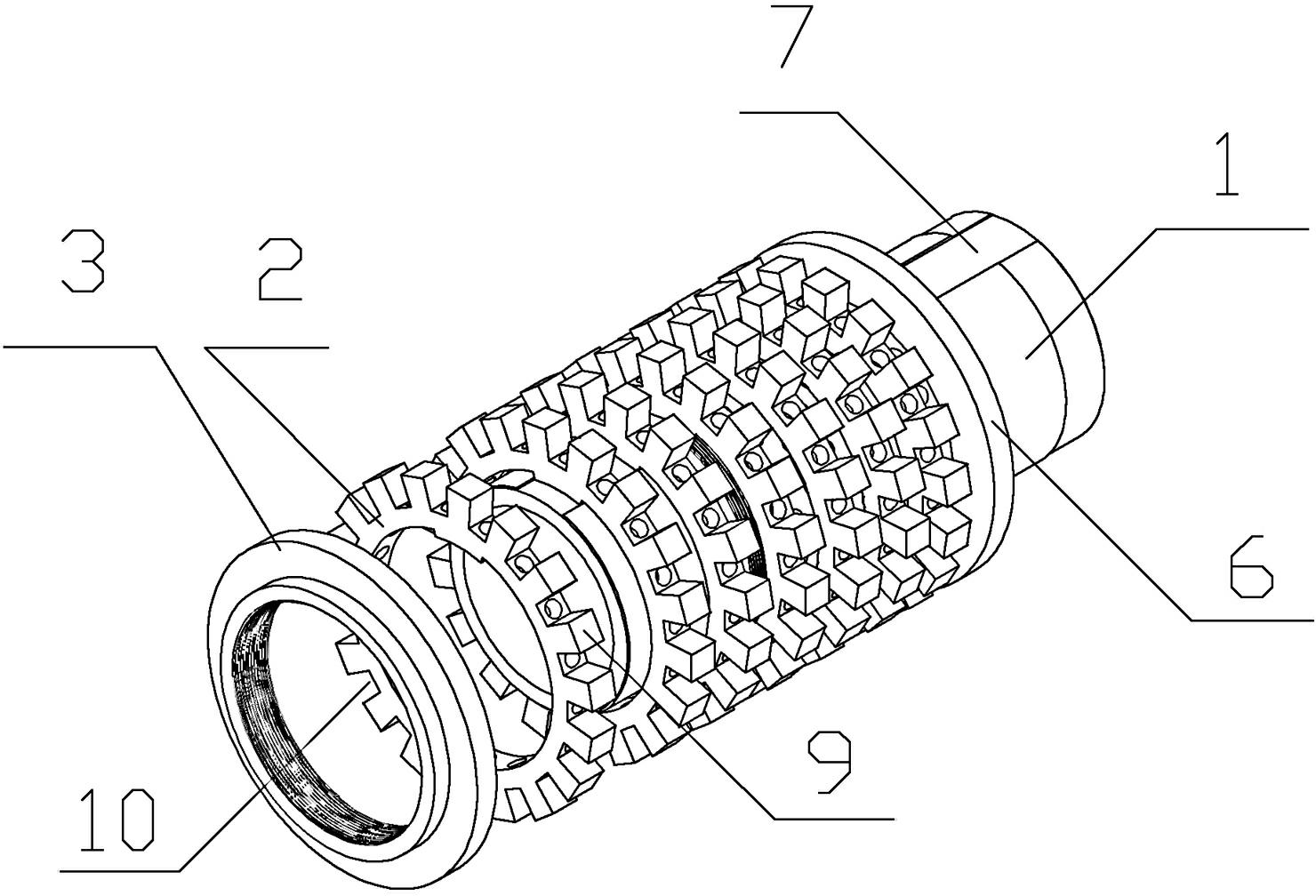

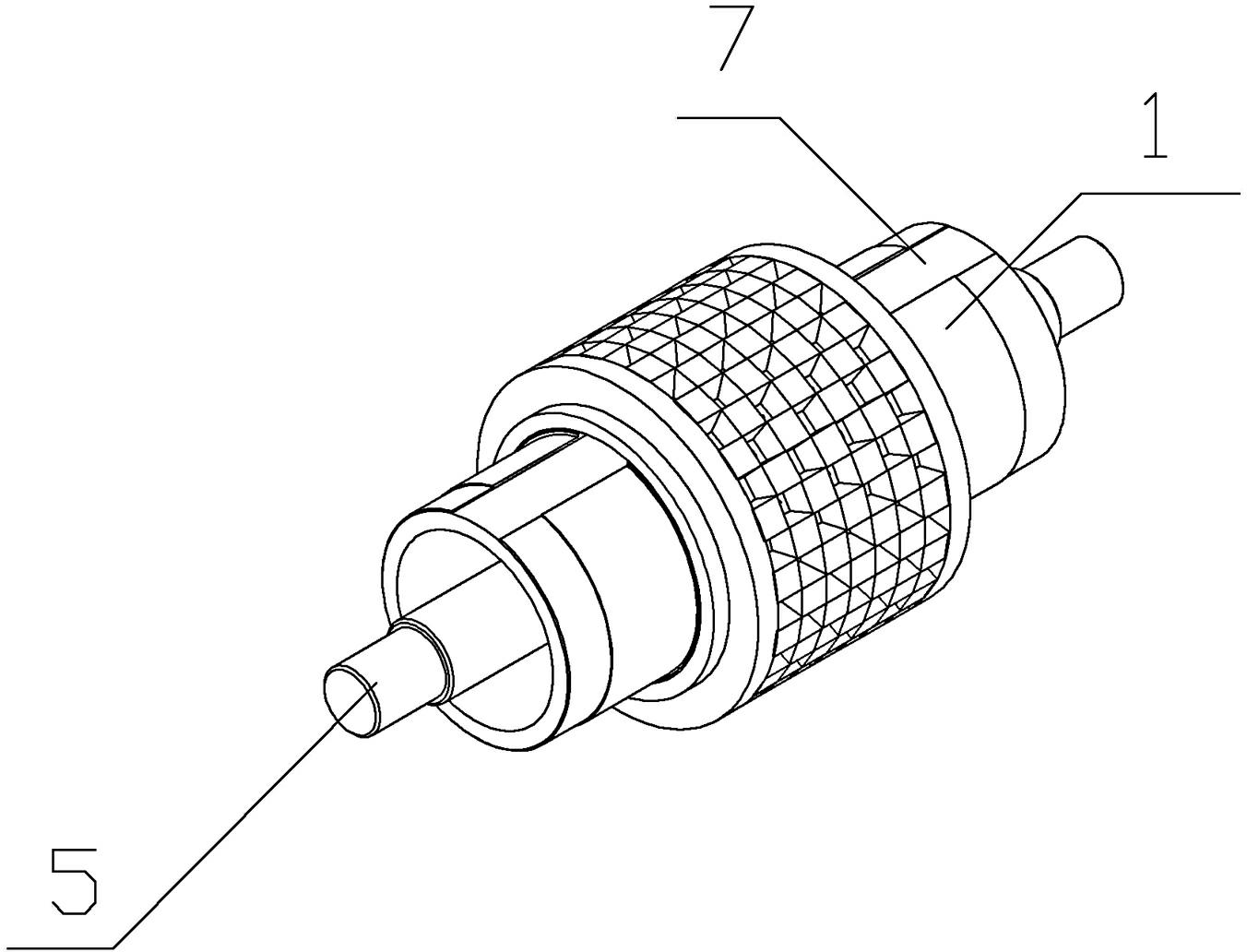

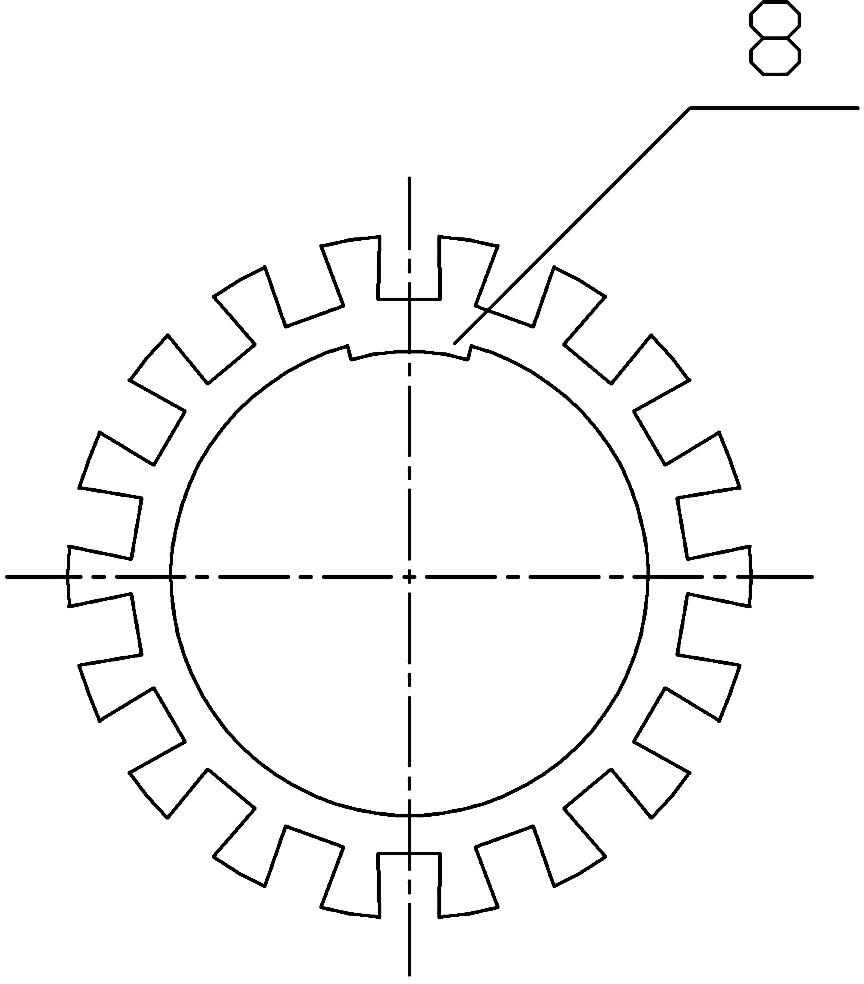

[0014] Such as figure 1 , figure 2 As shown, the extrusion roller of the present invention is assembled from a cavity main shaft 1, hob ring 2, lock nut 3, ejector rod 4 and eccentric ejector shaft 5, and 7 rows of separate hob rings 2 are set in the hollow On the outer peripheral surface of the cavity main shaft 1, a positioning plate 6 is provided on the cavity main shaft at the closed end of the hob ring 2 (that is, the end of the hob ring set on the cavity main shaft in the first row), which is useful for restricting and fixing the hob The closed end of the ring 2 and the open end of the hob ring (that is, the end of the hob ring set on the cavity main shaft in the last row) are fixed with the thread of the cavity main shaft 1 through the lock nut 3, and the axial surface of the cavity main shaft 1 There is a keyway 7 in the axial direction, combined with image 3 As shown, the inner ring of the hob ring 2 is provided with a flat key 8 matching the keyway 7, and the fla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com