A kind of ferromanganese composite oxide catalyst for simultaneous denitrification and mercury removal and preparation method thereof

A technology of composite oxides and catalysts, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problem that there is no flue gas mercury emission control technology, and the treatment cost is expensive , trace element pollution and other issues, to achieve the effect of improving anti-poisoning performance, high activity and selectivity, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] 1) Dry the titanium dioxide carrier at 110° C. for 12 hours, and take 15 g;

[0042] 2) 3.58g 50% Mn(NO 3 ) 2 solution and 2.02g Fe(NO 3 ) 3 9H 2 O was dissolved in deionized water at 25°C to make the volume of the solution reach 19ml, and stirred at room temperature for 1 hour to make it evenly mixed to obtain a solution;

[0043] 3) Using the equal volume impregnation method, add the carrier obtained in step 1) to the solution obtained in step 2), stir rapidly to mix the solid and liquid evenly, use an ultrasonic cleaner to ultrasonically oscillate for 10 minutes, and then place it in a cool place for 12 hours ;

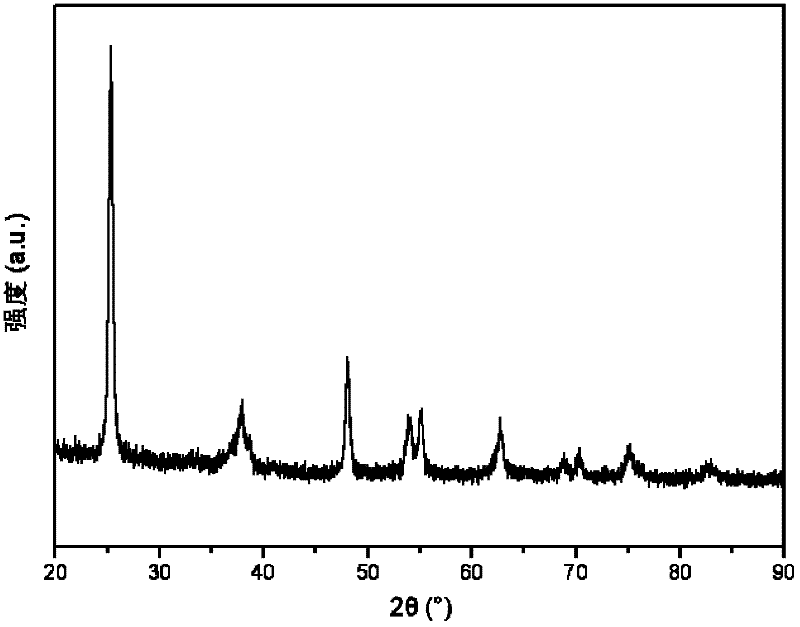

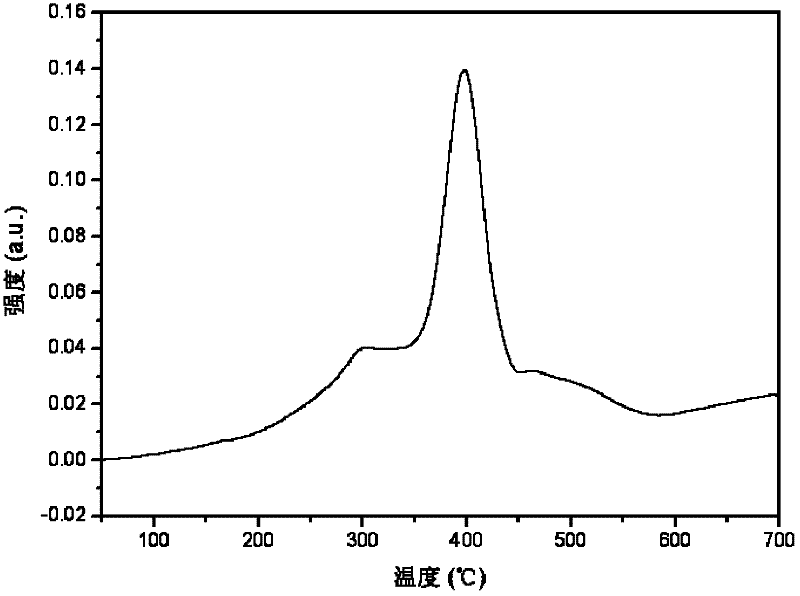

[0044] 4) The obtained mixture was dried in a constant temperature drying oven at 110° C. for 12 hours, and then calcined at 500° C. for 5 hours to obtain a catalytic oxidation catalyst with ferromanganese composite oxide as the active component and titanium dioxide as the carrier.

[0045] The prepared catalyst was pulverized and sieved to obtain cata...

Embodiment 2

[0047] 1) Dry the titanium dioxide carrier at 110° C. for 12 hours, and take 15 g;

[0048] 2) 7.16g 50% Mn(NO 3 ) 2 solution and 12.12g Fe(NO 3 ) 3 9H 2 O was dissolved in deionized water at 25°C to make the volume of the solution reach 19ml, and stirred at room temperature for 1 hour to make it evenly mixed to obtain a solution;

[0049] 3) Using the equal volume impregnation method, add the carrier obtained in step 1) to the solution obtained in step 2), stir rapidly to mix the solid and liquid evenly, use an ultrasonic cleaner to ultrasonically oscillate for 10 minutes, and then place it in a cool place for 12 hours ;

[0050] 4) The obtained mixture was dried in a constant temperature drying oven at 110° C. for 12 hours, and then calcined at 500° C. for 5 hours to obtain a catalytic oxidation catalyst with ferromanganese composite oxide as the active component and titanium dioxide as the carrier.

[0051] Using the activity evaluation device and method in Example 1,...

Embodiment 3

[0056] 1) Dry the titanium dioxide carrier at 110° C. for 12 hours, and take 15 g;

[0057] 2) 10.74g 50% Mn(NO 3 ) 2 solution and 16.16g Fe(NO 3 ) 3 9H 2 O was dissolved in deionized water at 25°C to make the volume of the solution reach 19ml, and stirred at room temperature for 1 hour to make it evenly mixed to obtain a solution;

[0058] 3) Using the equal volume impregnation method, add the carrier obtained in step 1) to the solution obtained in step 2), stir rapidly to mix the solid and liquid evenly, use an ultrasonic cleaner to ultrasonically oscillate for 10 minutes, and then place it in a cool place for 12 hours ;

[0059] 4) The obtained mixture was dried in a constant temperature drying oven at 110° C. for 12 hours, and then calcined at 500° C. for 5 hours to obtain a catalytic oxidation catalyst with ferromanganese composite oxide as the active component and titanium dioxide as the carrier.

[0060] Using the activity evaluation device and method in Example 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com