Method for forming semiconductor integrated device

An integrated device and semiconductor technology, applied in the field of semiconductor integrated device formation, can solve the problems of low process integration and material waste process steps, and achieve the effect of saving process steps and improving process integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

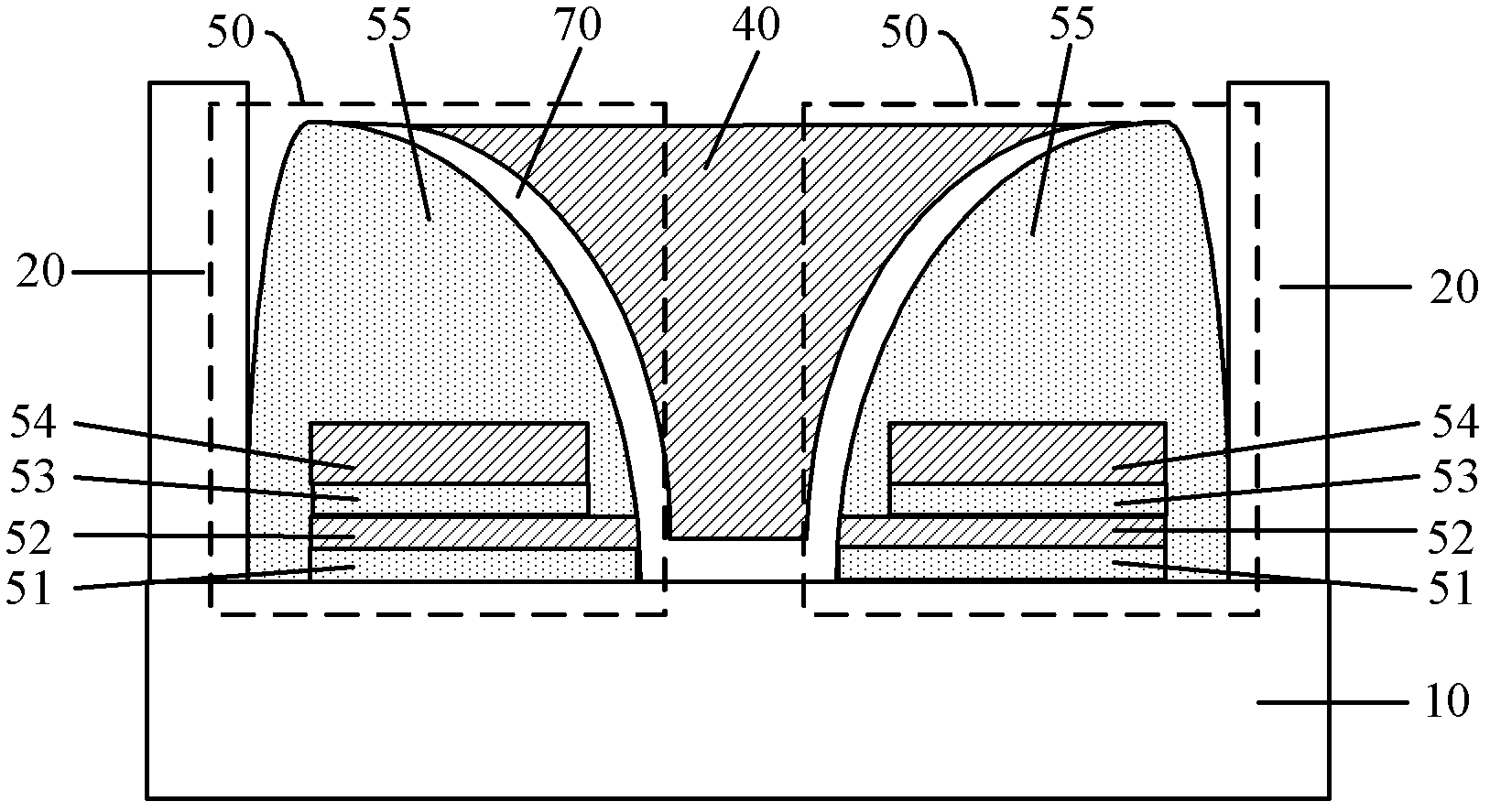

[0037] When forming split-gate flash memory and polysilicon resistors on the same substrate, since the manufacturing process of the formed polysilicon resistors includes forming a polysilicon layer and etching the polysilicon layer, if the process of forming a split-gate flash memory is to be deposited After the polysilicon layer is etched away, another polysilicon layer is deposited to form the polysilicon resistor, which not only increases the process steps but also wastes the raw materials for depositing the polysilicon layer.

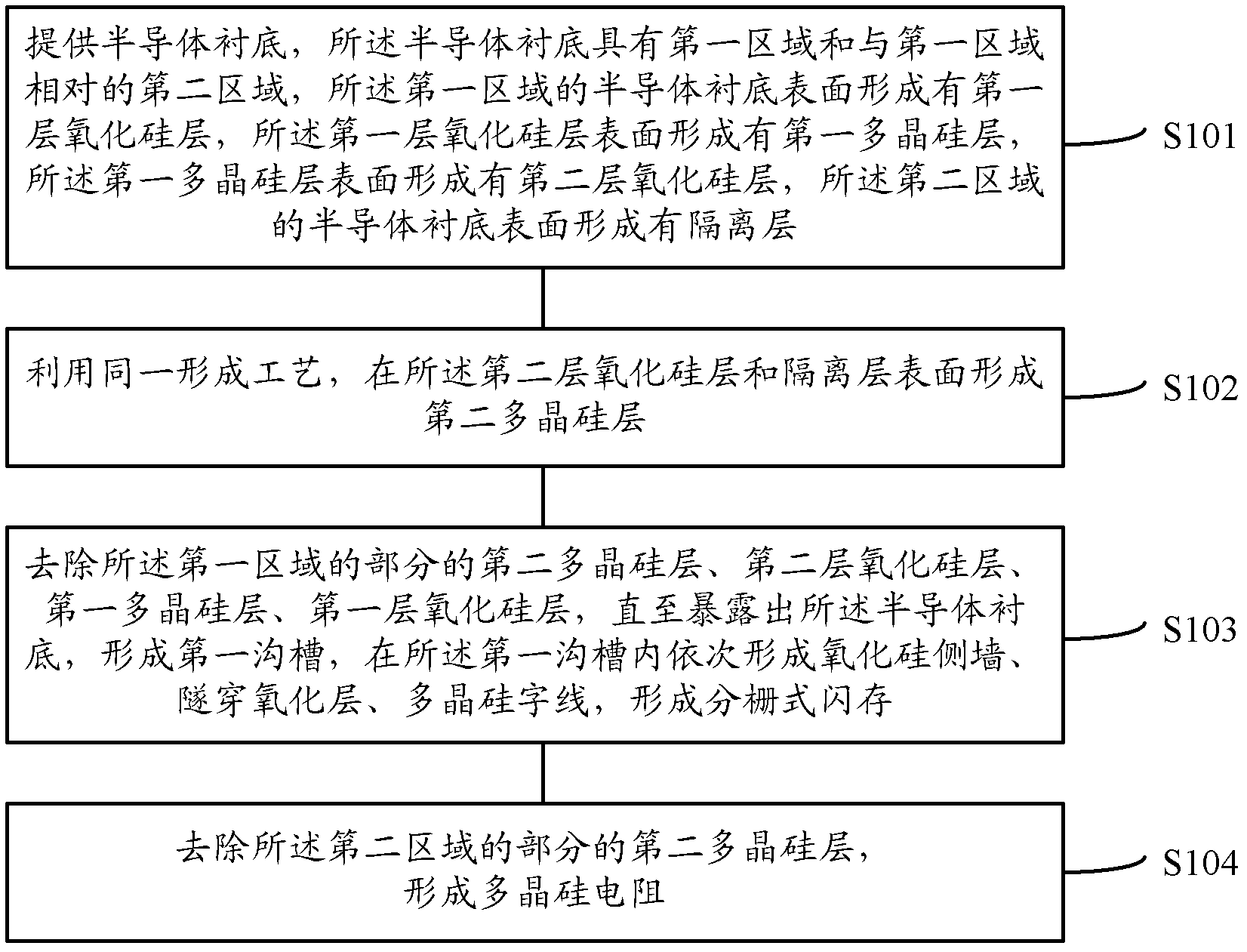

[0038] To this end, the inventor proposed a method for forming a semiconductor integrated device after research, including: providing a semiconductor substrate, the semiconductor substrate has a first region and a second region opposite to the first region, the first region A first silicon oxide layer is formed on the surface of the semiconductor substrate, a first polysilicon layer is formed on the surface of the first silicon oxide layer, and a sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com