Large-area bolted tile dry-hanging construction method

A construction method and large-area technology, applied in covering/lining, construction, building construction, etc., can solve the problems of poor safety, high material consumption, high cost, and ensure stability and safety, smooth tile surface, and uniform gap. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

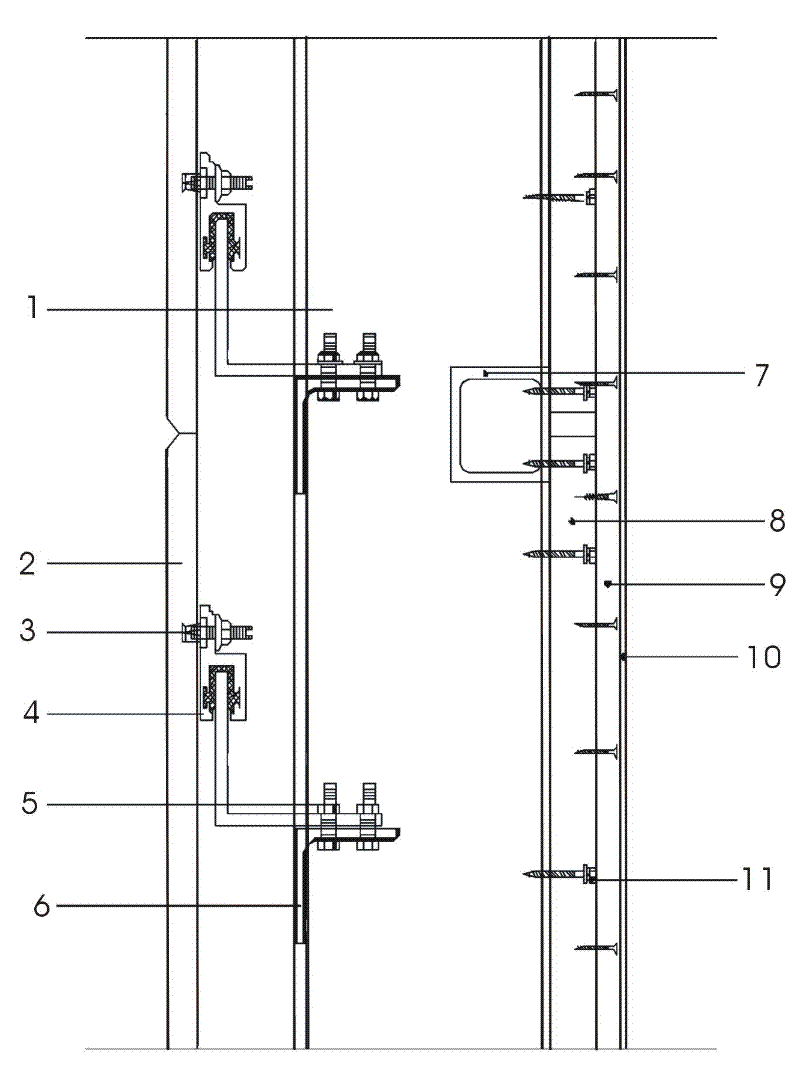

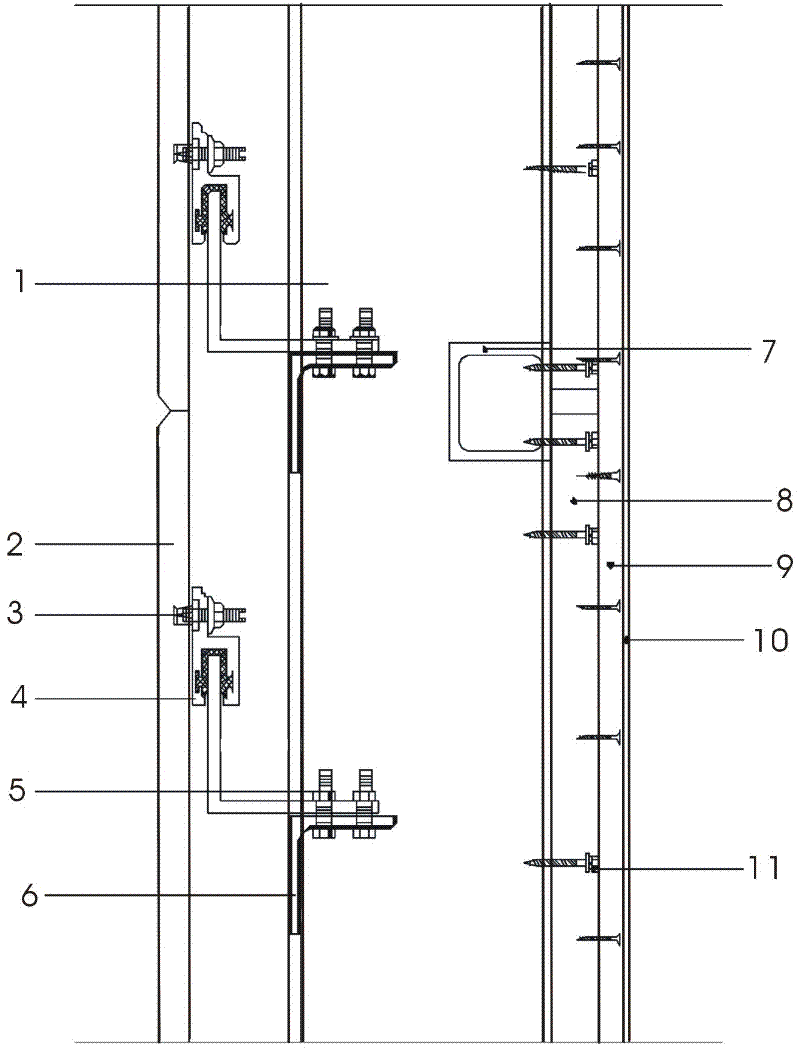

[0007] Now refer to the attached figure 1 , are described as follows in conjunction with the embodiments: The large-area bolted dry-hanging construction method of tiles of the present invention includes galvanized iron square pipe 1, dry-hanging tiles 2, expansion bolts 3, aluminum alloy fasteners 4, stainless steel bolts 5, angle steel 6. Iron square pipe 7, woodworking board 8, paper-faced gypsum board 9, putty latex paint protective layer 10 and tail screw 11 are composed. The galvanized iron square pipe 1 is the main body. On one side of the galvanized iron square pipe 1, the angle steel 6 is fixedly connected. At the same time, the aluminum alloy fastener 4 is connected. The outer end of the expansion bolt 3 is connected with the inner surface of the dry-hanging tile 2. On the other side of the galvanized iron square pipe 1, an iron square pipe 7 is arranged using a turning nail 11, and a woodworking board 8 is arranged on the outside of the galvanized iron square pipe 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com