A kind of curd gum and preparation method thereof

A technology of cod gum and bacteria strains, applied in the biological field, can solve the problems of low yield, high cost, and less application research, and achieve the effect of stable genetic performance and short fermentation cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

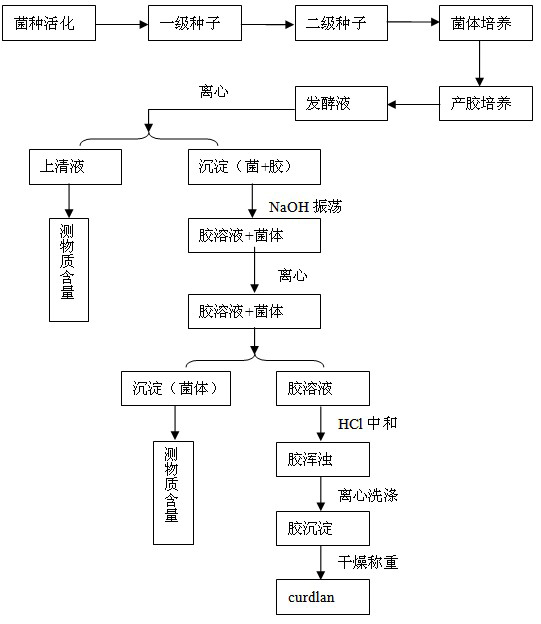

[0051] The specific steps for preparing cod gum are as follows:

[0052] 1. Strain activation: Streak the strain of Agrobacterium sp. fcyn1 (Accession No. CGMCC 5103) stored at -80°C on an LB plate containing 1.5% agarose to obtain a single colony;

[0053] 2. Primary seed culture: Take a single colony with good shape and growth and inoculate it in a 50 mL Erlenmeyer flask containing 10 mL LB medium, 30°C, 200 RPM, and shake for about 48 hours to obtain the primary seed bacteria;

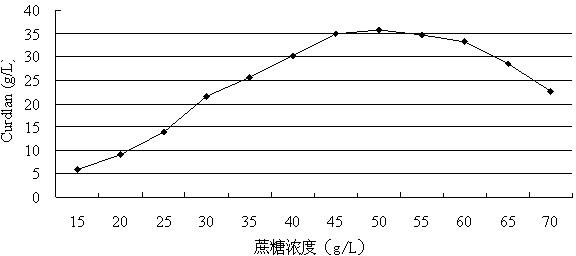

[0054] 3. Secondary seed culture: Culture 10 mL of primary seed fungus in 50-fold dilution respectively in five 1 L Erlenmeyer flasks containing 100 mL of secondary seed medium (medium composition g / L: sucrose 20, yeast extract 10,KH 2 PO 4 1.74, MgSO 4 ·7H 2 O 0.49, pH 7.0), cultured at 30°C, 200 RPM for 48h;

[0055] 4. Bacteria culture: transfer about 0.5 L of second-grade seed cells into culture medium containing 20 L of bacteria, and the composition of the medium is g / L: sucrose 15, yeast...

Embodiment 2

[0064] What is different from embodiment 1 is 5 steps, namely:

[0065] Fermentation culture: Transfer about 20L of bacterial culture liquid into a fermentation tank containing 200L of fermentation medium, the fermentation medium is g / L: 53, fish meal 3.0, KH 2 PO 4 0.45, MgSO 4 ·7H 2 O 0.55, potassium citrate 0.35 and inorganic salt concentrate 0.3% (v / v), inorganic salt concentrate composition g / L: FeCl 3 1.0, MnCl 2 1.0, NaCl 1.0, CaCl 2 1.0), pH 5.5-6.0, at 600 RPM, air flow 2.0 v / vm, and with 4M NaOH and 3M H 2 SO 4 After 38 hours of fermentation, 10% (v / v) 500g / L sucrose (about 20L) was added, and then cultivated under the same conditions for 38 hours, at which time 10% (v / v) 500g / L sucrose (about 20L) was added again. After culturing under the same conditions for 38 h, the fermentation medium was obtained.

Embodiment 3

[0067] What is different from embodiment 1 is 5 steps, namely:

[0068] Fermentation culture: Transfer about 20L of bacterial culture liquid into a fermentation tank containing 100L of fermentation medium, the fermentation medium is g / L: sucrose 55, yeast powder 3.0, KH 2 PO 4 0.5, MgSO4 ·7H 2 O 0.6, potassium citrate 0.4 and inorganic salt concentrate 0.3% (v / v), inorganic salt concentrate composition g / L: FeCl 3 1.0, MnCl 2 1.0, NaCl 1.0, CaCl 2 1.0), pH 5.5-6.0, at 600 RPM, air flow 1.5-2.0 v / vm, and with 4 M NaOH and 3 M H 2 SO 4 After adding 10% (v / v) 500 g / L sucrose for 36 h of fermentation culture, cultured under the same conditions for 36 h, then added 10% (v / v) 500 g / L sucrose again, and cultured under the same conditions for 36 h Afterwards, the fermented liquid is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com