A kind of solvent-free synthesis method of metal polyazole framework material

A framework material and synthesis method technology, applied in the direction of alkali metal compounds, chemical instruments and methods, alkali metal oxides/hydroxides, etc., can solve the problems of high cost, difficulty in activation, low reaction yield, etc., and achieve production efficiency High, high product yield, high purity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] High-temperature and high-efficiency preparation of Example 1 MAF-4 (that is, SOD type 2-methylimidazolium zinc)

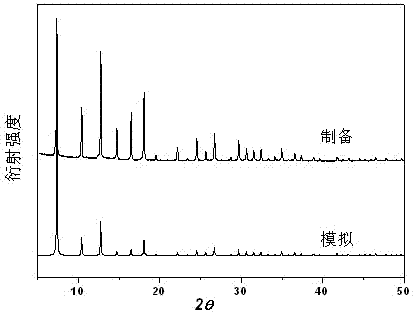

[0034] After grinding ZnO (200 mg, 2.5 mmol) and Hmim (410 mg, 5.0 mmol) uniformly, they were placed in a 15 mL reaction kettle with a polytetrafluoroethylene substrate, nitrogen was blown for 5 minutes, and the mixture was sealed and heated to 180 °C and kept After 12 hours, a white powder product was obtained with a yield of about 100%. The X-ray diffraction pattern of the obtained MAF-4 and the comparison result of the diffraction pattern of its single crystal simulation are shown in figure 1 .

Embodiment 2

[0035] Example 2 High-temperature and efficient direct molding preparation of MAF-4

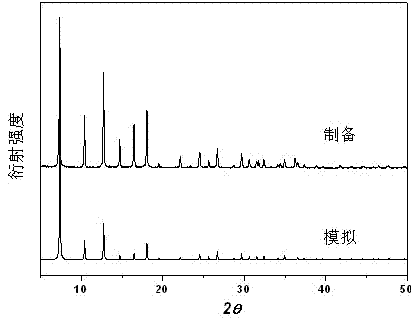

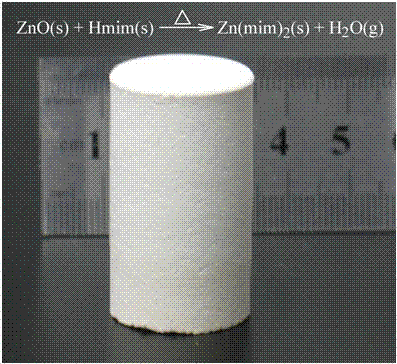

[0036] After grinding ZnO (2.44 g, 30 mmol) and Hmim (4.93 g, 60 mmol) evenly, they were naturally filled in a 15 mL reaction vessel with a polytetrafluoroethylene substrate, heated to 180 °C and kept for 12 hours in an airtight manner to obtain White molded product, the yield is about 100%. The X-ray diffraction pattern of the obtained MAF-4 and the comparison result of the diffraction pattern of its single crystal simulation are shown in figure 2 . Product photo see image 3 , the scanning electron microscope results see Figure 4 .

Embodiment 3

[0037] Example 3 High-temperature and efficient preparation of MAF-27 (i.e. nbo type 3-(3-methyl-2-pyridine)-5-(4-pyridine)-1,2,4-triazole magnesium)

[0038] in Mg(OH) 2 (15 mg, 0.25 mmol) was added to Hmdpt (119 mg, 0.50 mmol), after grinding evenly, it was placed in a 10 mL glass tube, nitrogen gas was passed for 5 minutes, sealed and heated to 300 ° C and kept for 16 hours to obtain a white powder, The yield is about 100%. The X-ray diffraction pattern of the obtained MAF-27 and the comparison result of the diffraction pattern of its single crystal simulation are shown in Figure 5 . Product scanning electron microscope results see Figure 6 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com