A special high-performance cement for nuclear power plant nuclear island and its preparation method

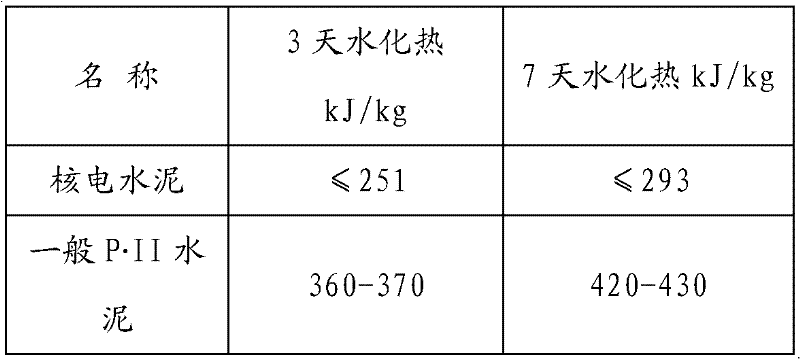

A high-performance, nuclear power plant technology, applied in the field of building materials, can solve problems such as poor sulfate resistance, high cement hydration heat, and cement that cannot meet the needs of nuclear power construction, and achieve the effect of reducing the hydration rate and cement hydration heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

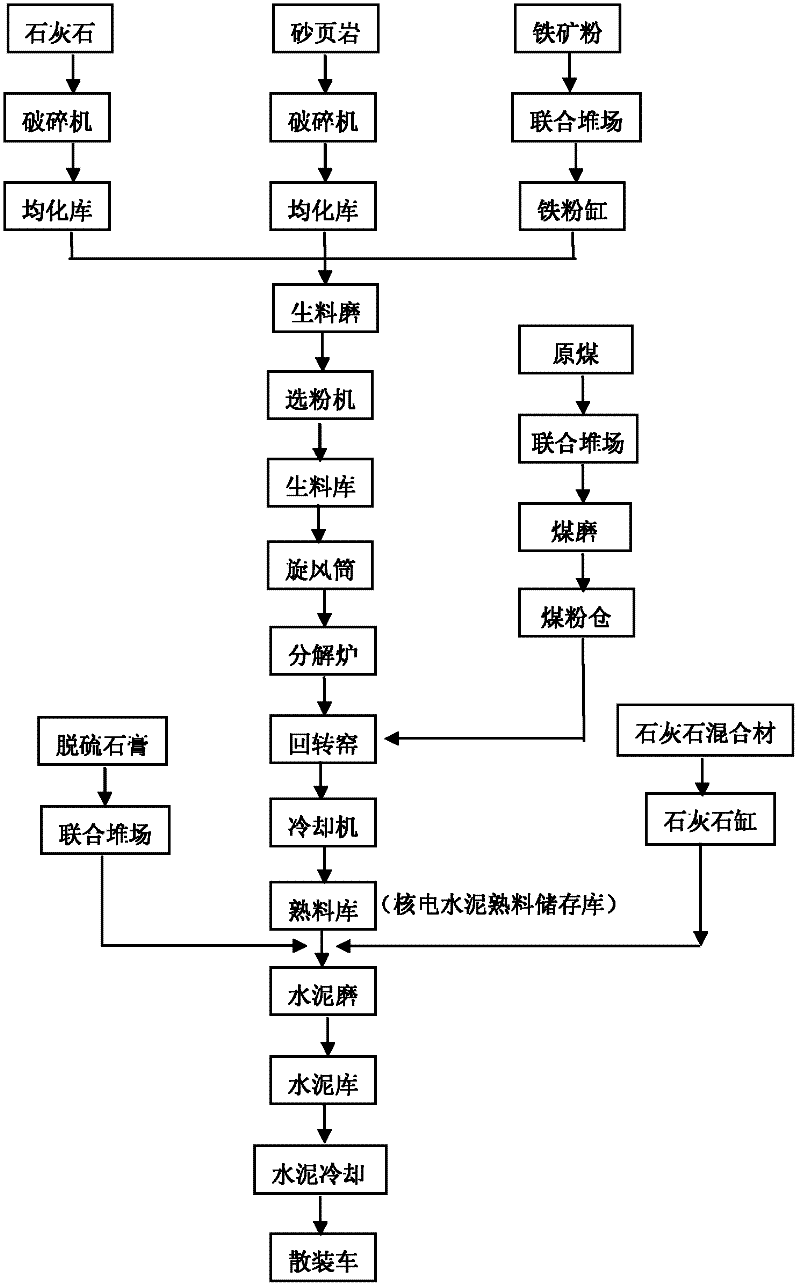

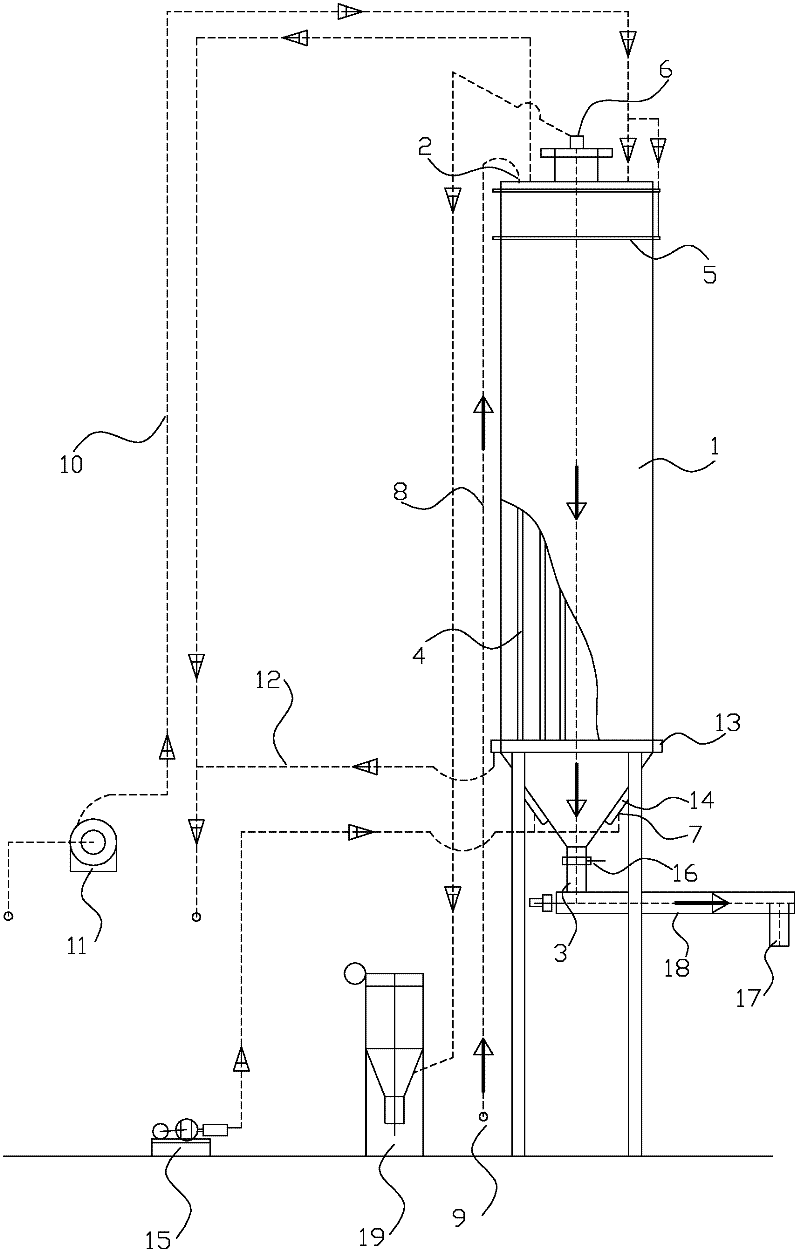

Method used

Image

Examples

Embodiment 2

[0096] (1) The batching scheme of special high-performance cement for nuclear power plant nuclear island described in the present embodiment is as follows:

[0097] Cement clinker 90.5%, limestone mixture 4.5%, desulfurized gypsum 5.0%. Among them, the formula used for the clinker is KH: 0.910±0.01; SM: 2.00±0.1; IM: 1.00±0.1. The clinker is prepared by calcining the raw meal in a rotary kiln. The ratio of raw meal preparation is 85% limestone, Sand shale 10%, iron ore powder 5%. Al of limestone admixture 2 o 3 ≤2.5%.

[0098] The main components of the clinker are controlled as follows: C 3 S≤57.0%, C 3 A≤6.0%, Cl - ≤0.05%, MgO≤5.0%, SO 3 ≤3.5%, f-CaO≤1.0%.

[0099] (2) the preparation method of special high-performance cement for nuclear power plant nuclear island described in the present embodiment is as follows:

[0100] 1. The control of raw and fuel materials is as in Example 1.

[0101] 2. The quality control points and control items of the production process ...

Embodiment 3

[0117] (1) The batching scheme of special high-performance cement for nuclear power plant nuclear island described in the present embodiment is as follows:

[0118] Cement clinker 92%, limestone mixture 4.0%, desulfurized gypsum 4.0%. The formula used for the clinker is KH: 0.910±0.01; SM: 2.00±0.1; IM: 1.00±0.1. The clinker is prepared by calcining the raw meal in a rotary kiln. The ratio of raw meal preparation is 80% limestone, Sand shale 10%, iron ore powder 10%. Al of limestone admixture 2 o 3 ≤2.5%.

[0119] The main components of the clinker are controlled as follows: C 3 S≤57.0%, C 3 A≤6.0%, Cl - ≤0.05%, MgO≤5.0%, SO 3 ≤3.5%, f-CaO≤1.0%.

[0120] (2) the preparation method of special high-performance cement for nuclear power plant nuclear island described in the present embodiment is as follows:

[0121] 1. The control of raw and fuel materials is as in Example 1.

[0122] 2. The quality control points and control items of the production process are as in Exa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com