Preparation method of water reducing agent mother liquor for concrete

A water-reducing agent and concrete technology, applied in the field of cement water-reducing agent, can solve problems such as inability to improve concrete strength, and achieve the effects of being beneficial to the construction of shotcrete, reducing costs, and reducing the amount of cement used.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

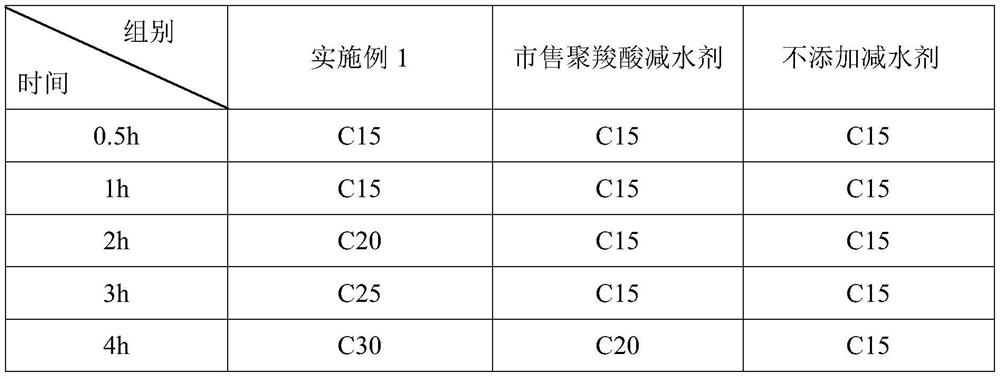

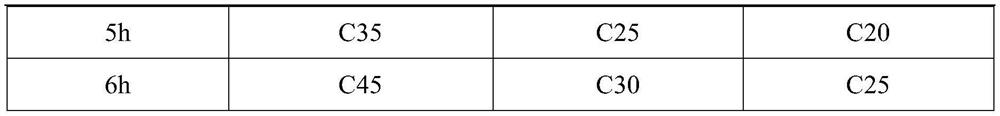

Examples

Embodiment 1

[0023] Embodiment 1: a kind of preparation method of mother liquor of water reducing agent for concrete, comprises following specific steps:

[0024] (1) Synthesis of esterified raw materials: Add polyethylene glycol and hydroquinone in sequence in a 250mL three-necked flask equipped with a dropping device, a thermometer, and a condenser, stir and heat up to 60°C, then add p-toluenesulfonic acid, Silica gel, after hydroquinone and p-toluenesulfonic acid are completely dissolved, add methacrylic acid drop by drop, the molar ratio of methacrylic acid to polyethylene glycol is 1.2:1, and heat up to within 2-3h Keep warm at 110°C and keep the reaction time at constant temperature for 9 hours. At this time, the esterification rate can reach 95%. Continue to store the product in an oil bath, let it cool down to room temperature slowly, and pour out the upper layer of ester liquid. The lower layer of light yellow solid is solidified Silica gel. The amount of hydroquinone added is 0....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com