An anatomical inspection method for quality, structure and performance of 70t to 600t steel ingots

An inspection method and technology of inspection methods, which are applied in the field of performance anatomy inspection, 70-ton to 600-ton steel ingot quality and organization, can solve the problems of large demand for corrosive liquid, large capital investment, and product scrapping, etc., and improve the solidification structure. , Improve the quality of ingots and eliminate casting defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

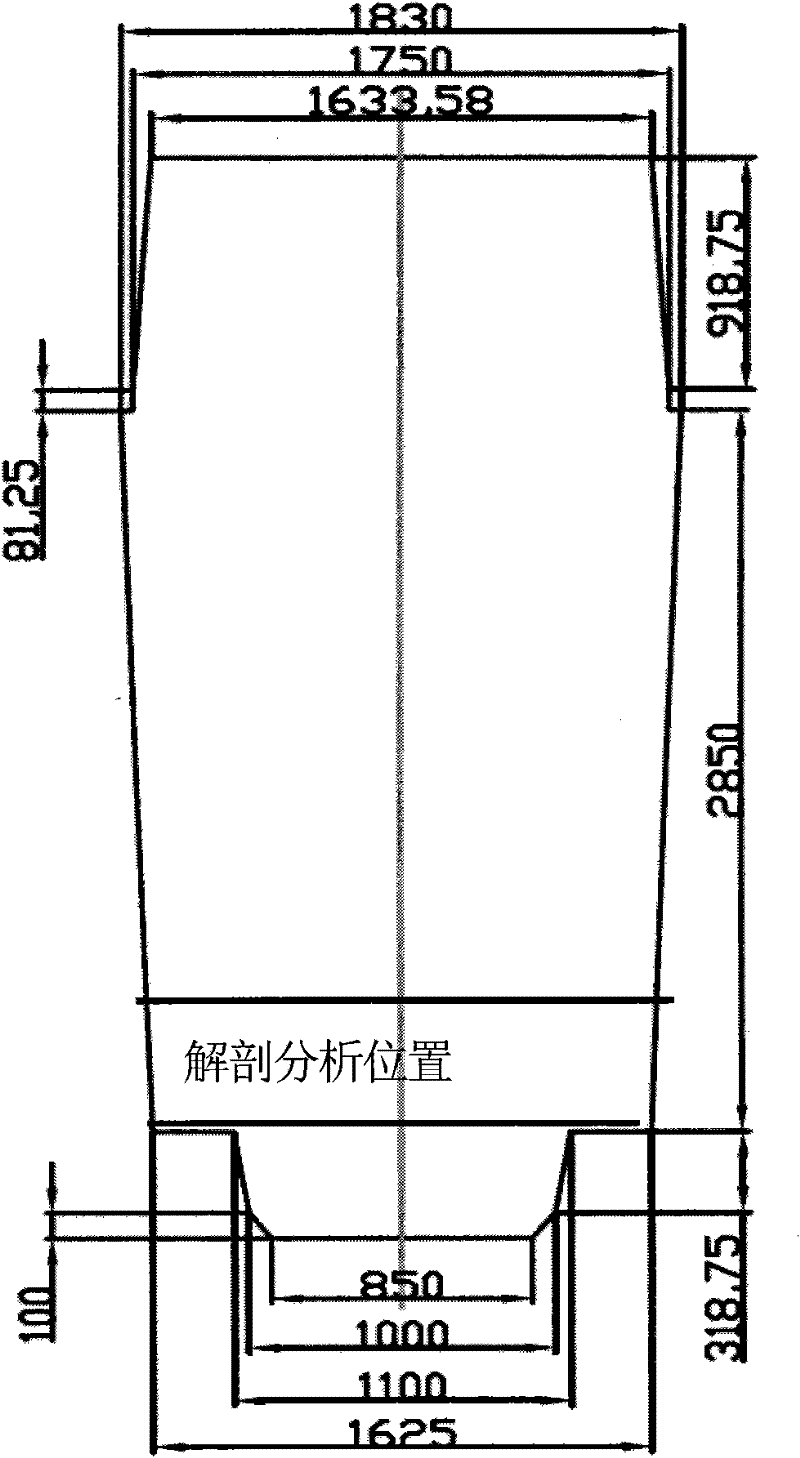

[0046] Anatomical inspection and analysis of 75 tons of steel ingots, the material of the steel ingot is 12Cr2Mo, and the size of the inspection surface is as follows figure 1 As shown, the bottom of the 75t steel ingot is mainly studied, and the specific operation procedures are as follows:

[0047] (1) After the ingot is cast, the surface temperature of the ingot body is demoulded at 880℃. After the ingot is demolded, use The oxygen blowing tube dissected the steel ingot in a height direction. The thickness of the final steel ingot sample is 450mm, which is the central part of the steel ingot. The bottom of the steel ingot is mainly taken. figure 1 Shown. The dissection process ensures that the flatness of the anatomical surface of the steel ingot is 80mm, while ensuring that the cutting heat affected area is less than 70mm, and the surface temperature of the steel ingot is 310°C when the ingot dissection is completed.

[0048] (2) The dissected sample is sent to the heat treatm...

Embodiment 2

[0056] Anatomical inspection and analysis of 120 tons of steel ingots, the material of the steel ingot is 30Cr2Ni4, and the size of the inspection surface is as follows Figure 4 , The specific procedures of the operation are as follows:

[0057] (1) The surface temperature of the ingot body is 900 ℃ when the steel ingot is demolded. The oxygen blowing tube dissected the steel ingot in a height direction. The final thickness of the steel ingot sample is 400mm, which is the central part of the steel ingot. The part of the ingot body with the riser of the steel ingot down 500mm is retained. Figure 4 Shown. The dissection process ensures that the flatness of the anatomical surface of the steel ingot is 60mm, and the cutting heat affected area is less than 50mm. The surface temperature of the steel ingot is 350℃ when the dissection of the steel ingot is completed.

[0058] (2) The dissected sample is sent to the heat treatment furnace at 300°C within 20 minutes, and kept at 300°C fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com