A light emitting diode and its manufacturing method

A technology of light-emitting diodes and manufacturing methods, applied in semiconductor/solid-state device manufacturing, light sources, electric light sources, etc., can solve the problems of nuts not being tightly fitted, poor heat dissipation of brackets, and complicated assembly processes, etc., to achieve convenient thermal design, light The effect of full shape and improved light output efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings of the embodiments.

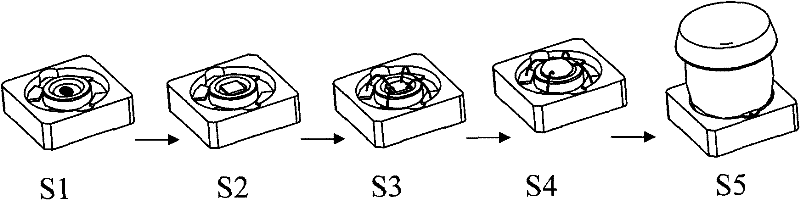

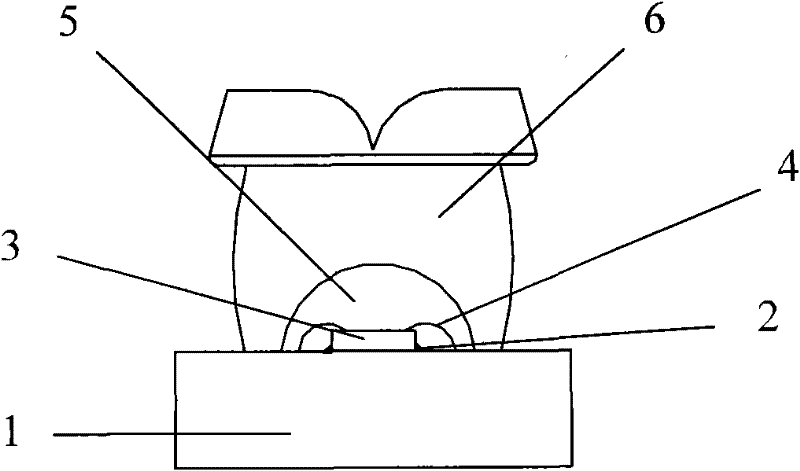

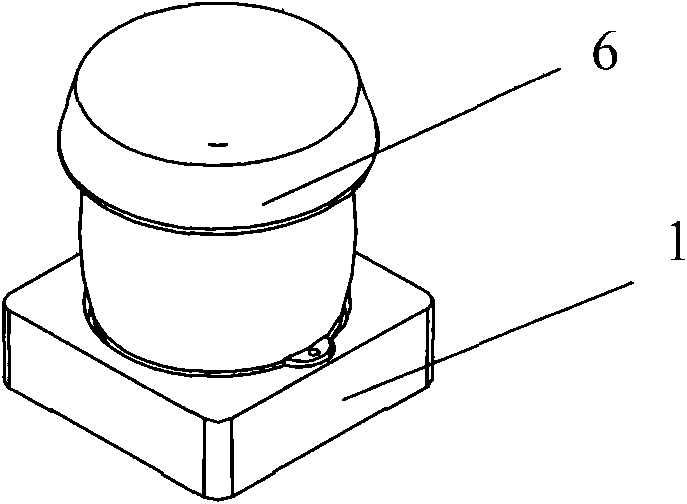

[0042] see figure 1 , see also Figure 2-Figure 4 . As shown in the figure, the manufacturing procedure of the light-emitting diode of the present invention is as follows:

[0043] S1, glue dispensing step, using equipment to directly point high thermal conductivity glue 2 (such as silver glue or solder paste) onto the carrier 1 . Under special requirements (such as the preparation of a higher-power light-emitting diode), eutectic soldering or flip-chip technology can be used, and this step can be omitted.

[0044] S2, crystal-bonding step, see also figure 2, the carrier 1 is a material with high thermal conductivity (it can be insulated, or it can be a conductor), and its composition can be a ceramic substrate, a combination bracket of PPA and metal columns, a metal PCB board, etc. The middle of the carr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com