Method for retarding emission of greenhouse gas by combusting fuel oil

一种温室气体、燃烧室的技术,应用在燃烧方法、燃烧器、燃烧类型等方向,能够解决很难达到节能、减少温室气体、很难体现出燃烧器节能环保的优越性等问题,达到节省燃油、成本低、节省能源的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

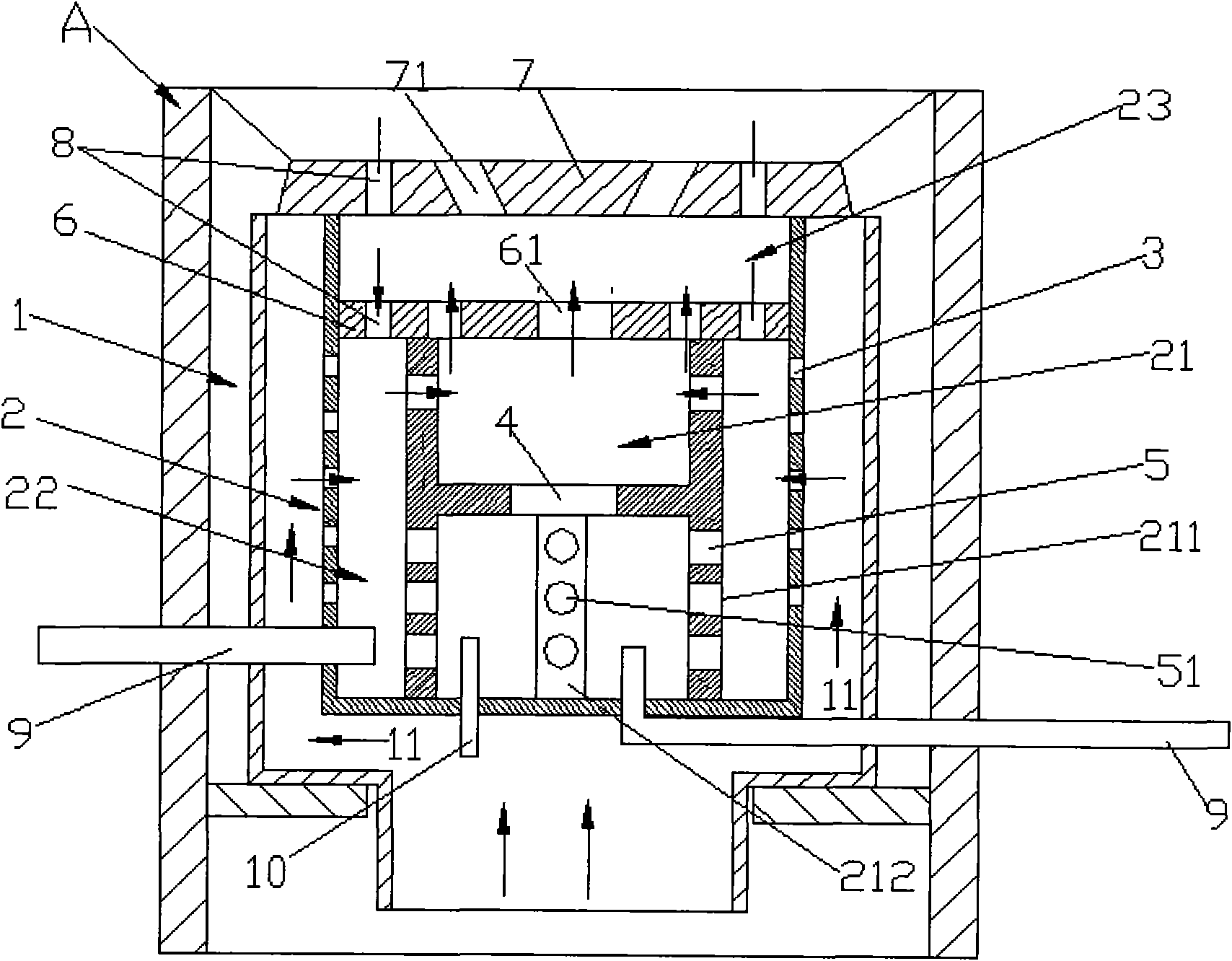

[0017] The method for mitigating greenhouse gas emissions by burning fuel oil of the present invention: the non-heat radiation fuel burner is arranged in the stove A.

[0018] A non-heat radiation fuel burner implementing the above method such as figure 1 As shown, the burner includes a furnace body 1 installed in a furnace A, a furnace body 2 is arranged in the furnace body 1, and a ventilation channel 11 is arranged between the furnace body 1 and the furnace body 2 . The furnace is composed of a shell with a plurality of through holes 3 , and the furnace 2 includes a primary fuel supply combustion chamber 21 , a secondary fuel supply combustion chamber 22 and a blocking chamber 23 . There are two oil delivery ports 9 connected in the furnace 2, each of which is connected by a connecting pipe, one connecting pipe is connected to the lower end of the primary oil supply combustion chamber 21, and the other connecting pipe is connected to the lower end of the secondary oil suppl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com