Comprehensive pipeline layout method for copper and copper alloy strip processing workshop

A technology that integrates pipelines and copper alloy plates. It is used in artificial islands, water conservancy projects, infrastructure projects, etc. It can solve the problems of messy scattered pipelines, poor cleanliness of workshops, and damage to the ground, so as to facilitate regular centralized maintenance and make workshops clean and beautiful. , the effect of reducing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The embodiment of the inventive method is described in detail below:

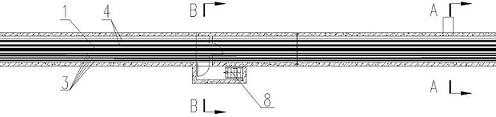

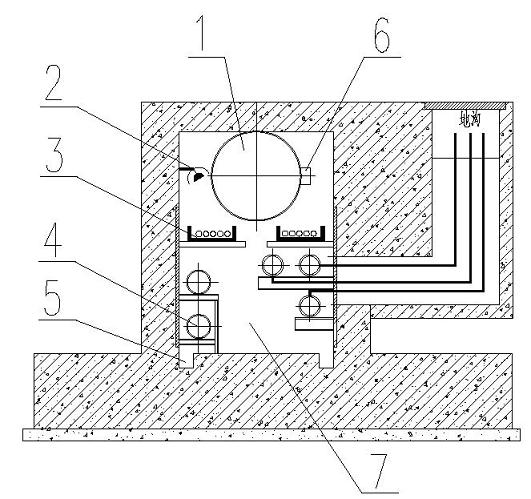

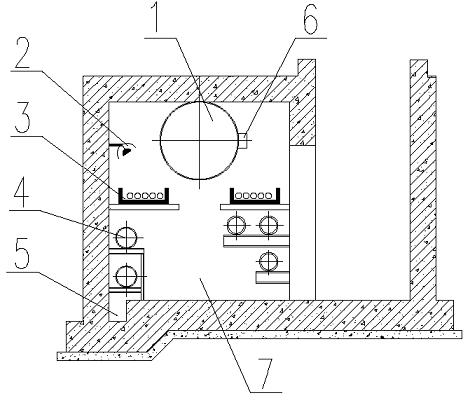

[0018] In a processing workshop, there are five spans in total. The workshop high and low voltage power distribution station and the workshop circulating water station are arranged on the first workshop span. Starting from the power distribution station and the circulating water station, the workshop is excavated along the columns of each span according to the design requirements. A closed underground roadway connected vertically and horizontally from span one to span five.

[0019] Under the premise of meeting the design specifications, the main cables and various medium pipes and other pipe network facilities in the workshop are arranged in the underground roadway, divided into upper, middle and lower floors according to their respective functional characteristics, and are pre-installed through the side wall of the roadway. The reserved holes are led to the ground of the workshop, and then docked a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com