Wide Screen Lime Block Wet Digester

A wide screening and lime technology, applied in the field of wide screening lime block wet digestion device, can solve the problems of fast wear speed of the device, noise of the crusher, power consumption and capital consumption, etc., and achieve long service life, good adaptability and reliability. high sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

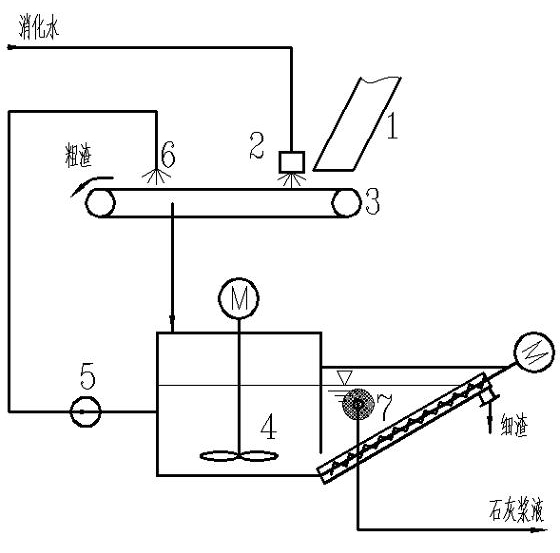

[0017] Embodiment 1: as figure 1 As shown, the wide-screened lime block wet digestion device in this embodiment includes a feed pipe 1, a liquid inlet distributor 2, a net chain machine 3, a digestion and slag extractor 4, a filter screen 7, a flushing water pump 5, and a flushing nozzle 6 , the net chain on the net chain machine 3 runs at a certain speed, the feed pipe above the net chain machine 3 transports lime blocks and falls on the net chain machine 3, and the digested water above the net chain machine 3 flows out through the liquid inlet distributor 2, and the The lime block is evenly wetted, and the lime begins to digest and disintegrate. The flushing water pump 5 pumps the digested slurry in the deslag extraction machine 4, and the digested part of the lime block is washed to form a slurry through the flushing nozzle 6 arranged at the end of the net chain machine 3, and flows into the In the digestion slag extraction machine 4, the digestion slag extraction machine 4...

Embodiment 2

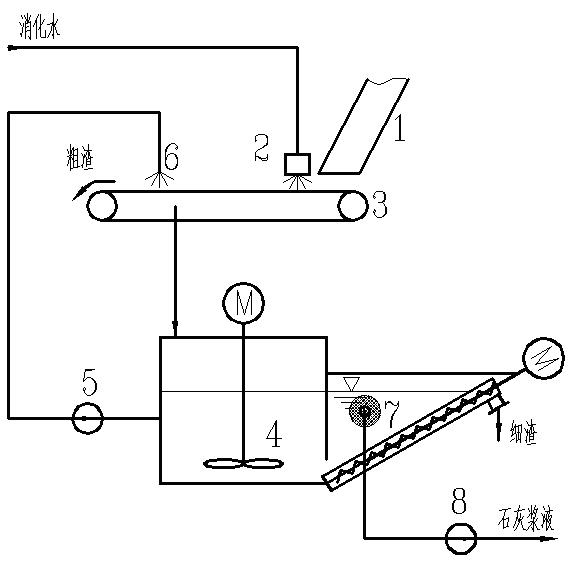

[0018] Embodiment 2: as figure 2 As shown, the wide-screened lime block wet digestion device in this embodiment includes a feed pipe 1, a liquid inlet distributor 2, a net chain machine 3, a digestion and slag extractor 4, a filter screen 7, a flushing water pump 5, and a flushing nozzle 6 , emulsification pump 8, net chain machine 3, digestion and slag extraction machine 4 and emulsification pump 8 are connected in sequence, and the emulsification pump 8 pumps the qualified slurry in the digestion and slag extraction machine 4 to the downstream equipment under pressure, and in the process of pressurized transportation, the more The large lime particles are broken, and the suction pipe of the emulsification pump 8 is connected to the filter screen 7.

Embodiment 3

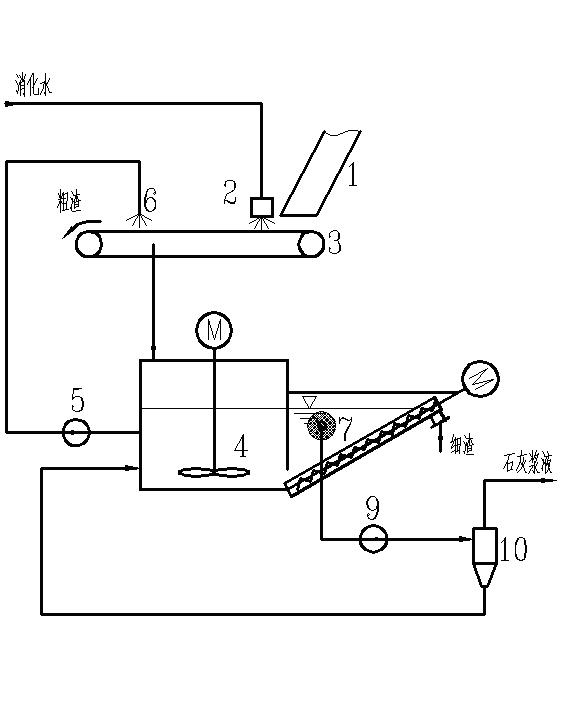

[0019] Embodiment 3: as image 3 As shown, the wide-screened lime block wet digestion device in this embodiment includes a feed pipe 1, a liquid inlet distributor 2, a net chain machine 3, a digestion and slag extractor 4, a filter screen 7, a flushing water pump 5, and a flushing nozzle 6 , cyclone pump 9, lime cyclone 10, net chain machine 3, digestion and slag extraction machine 4, cyclone pump 9 and lime cyclone 10 are connected in sequence, and the suction pipe of cyclone pump 9 is connected to filter screen 7 , the cyclone pump 9 pumps out the qualified slurry in the chemical slag extractor 4 and sends it to the lime cyclone 10 under pressure, the low-concentration slurry produced by the lime cyclone 10 is connected to the downstream equipment, and the high-concentration slurry produced by the lime cyclone 10 Backflow to digestion and slag extractor 4.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com