Method for producing ceramic glass colorant using waste chromium cobalt catalyst in fluorination process as raw material

A technology of cobalt catalyst and ceramic glass, which is applied in the field of waste chromium cobalt catalyst treatment, can solve environmental pollution and other problems, and achieve the effects of wide application range, strong coloring power and good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

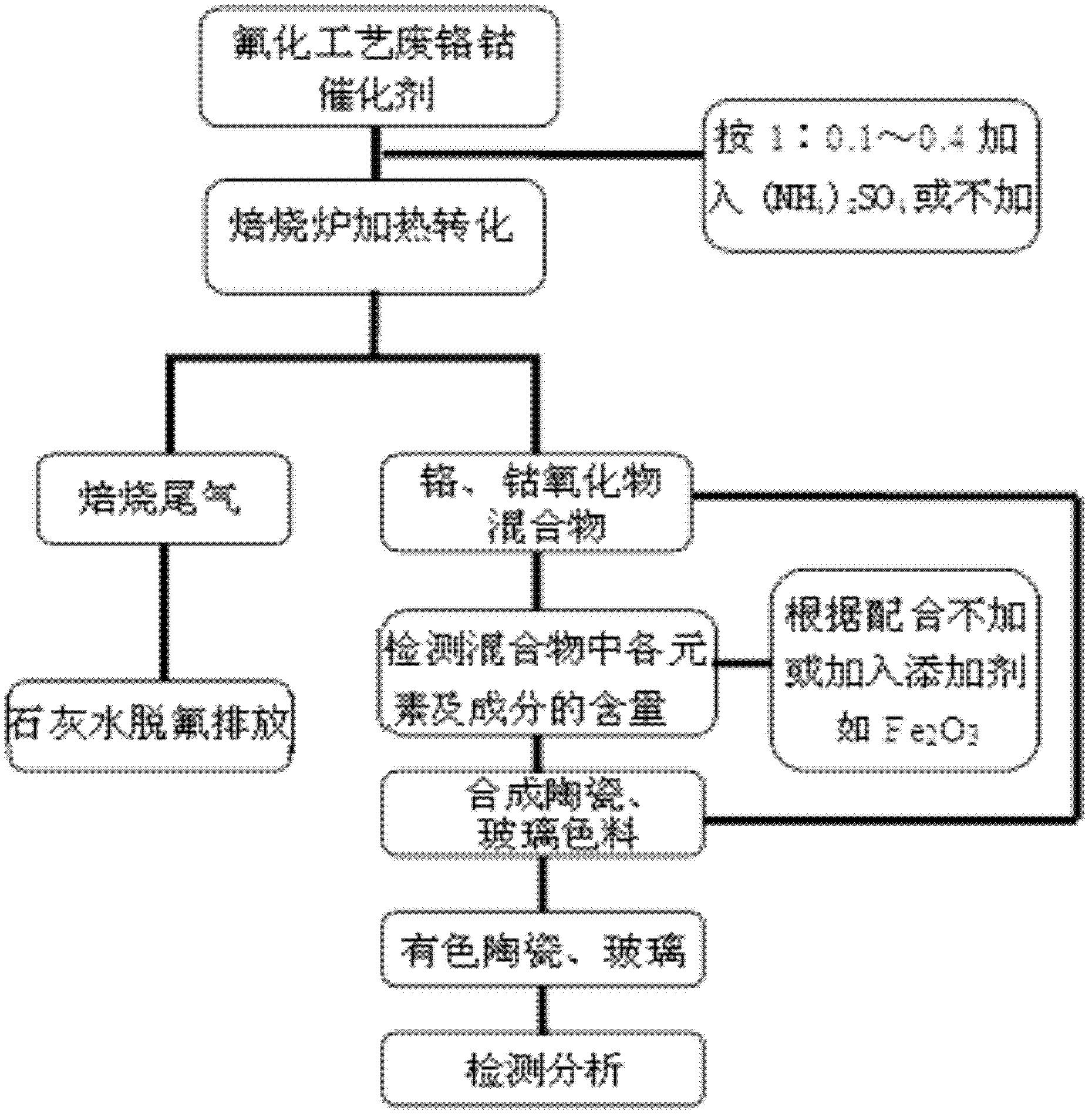

Method used

Image

Examples

preparation example Construction

[0045] 2) Preparation of colorants:

[0046] 2.2.1 Chromium oxide and cobalt oxide mixture are directly used as ceramic and glass pigments.

[0047] 2.2.2 Chromium oxide and cobalt oxide mixture are used as raw materials for synthetic ceramics and glass pigments.

[0048] The pigment preparation adopts Fe-Cr-Co, Fe-Cr-Co-Mn, Cr-Co-Al, Ti-Cr-Sb series pigments.

[0049] Weigh the following raw materials by mass percentage:

[0050]

[0051] The above-mentioned materials are mixed uniformly according to a certain ratio, ground to 40 mesh to 600 mesh and fully mixed to make batch materials. Then the mixture is synthesized in a high-temperature furnace, the synthesis temperature is 600°C-1300°C, and the holding time is 0-48 hours.

Embodiment 1

[0052] Embodiment 1: pottery, glass black pigment

[0053] 1.1 Heating conversion roasting of spent catalyst (preparation of chromium oxide cobalt oxide mixture)

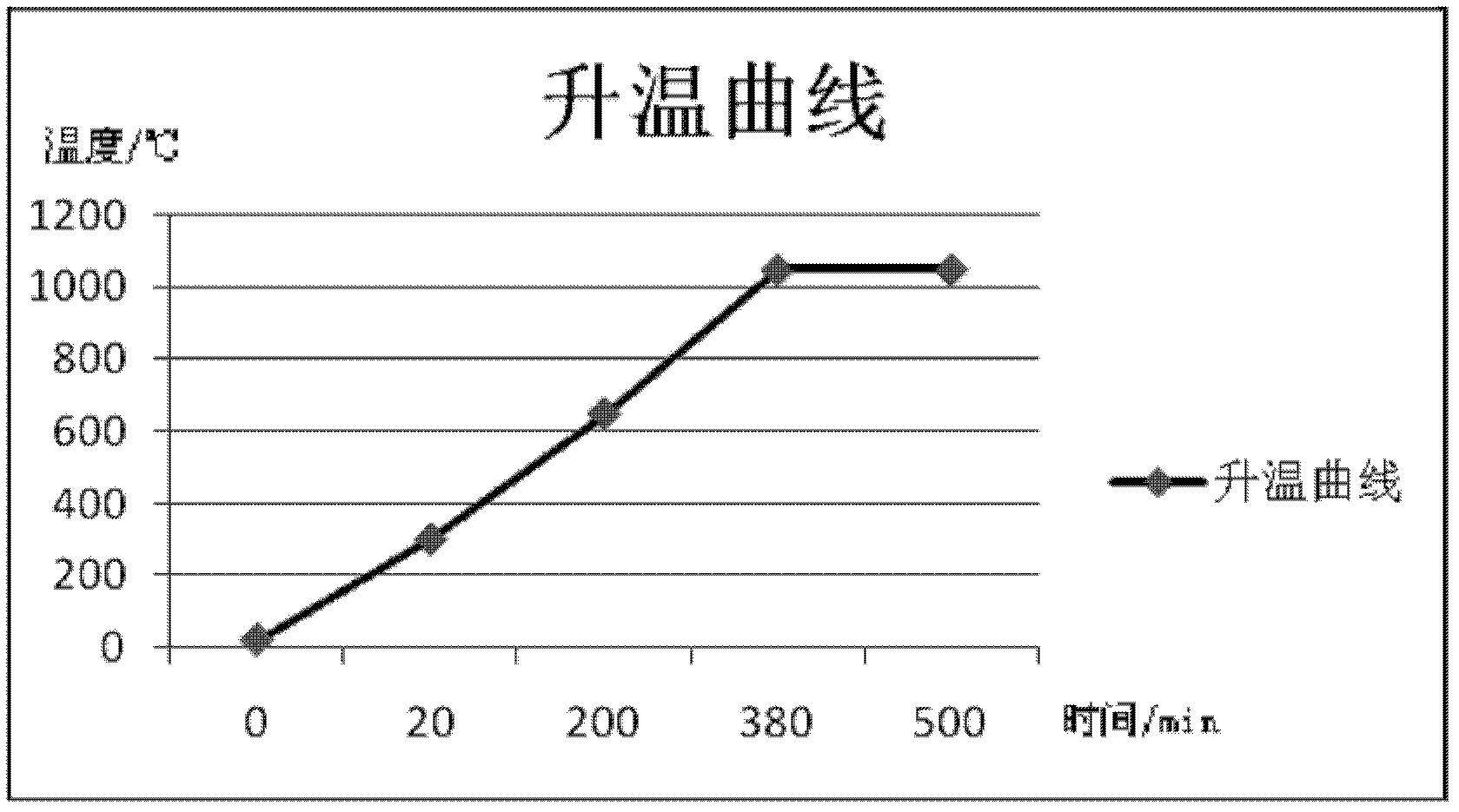

[0054] Mix the spent catalyst and ammonium sulfate at a ratio of 1:4, grind them to about 8 meshes, and then put them into a roasting furnace at a heating temperature of 150°C, and carry out heating conversion at this fixed temperature, and the heating curve is as follows: figure 2 shown.

[0055] The chromium and cobalt are converted from fluoride to chromium oxide cobalt oxide mixture. The mixture of chromium oxide and cobalt oxide is used as the raw material of ceramics and glass pigments, and the tail gas is discharged after defluorination of lime water.

[0056] 1.2 Preparation of colorant

[0057] Weigh the pulverized chromium oxide cobalt oxide mixture 36%, Fe 2 o 3 58%, MnCO 3 6%, V 2 o 5 0.05%, grind to about 400 mesh, put it into a resistance furnace for firing, the synthesis temperature is 600...

Embodiment 2

[0061] Embodiment 2: pottery, glass malachite green material

[0062] 2.1 Heating conversion roasting of spent catalyst (preparation of chromium oxide cobalt oxide mixture)

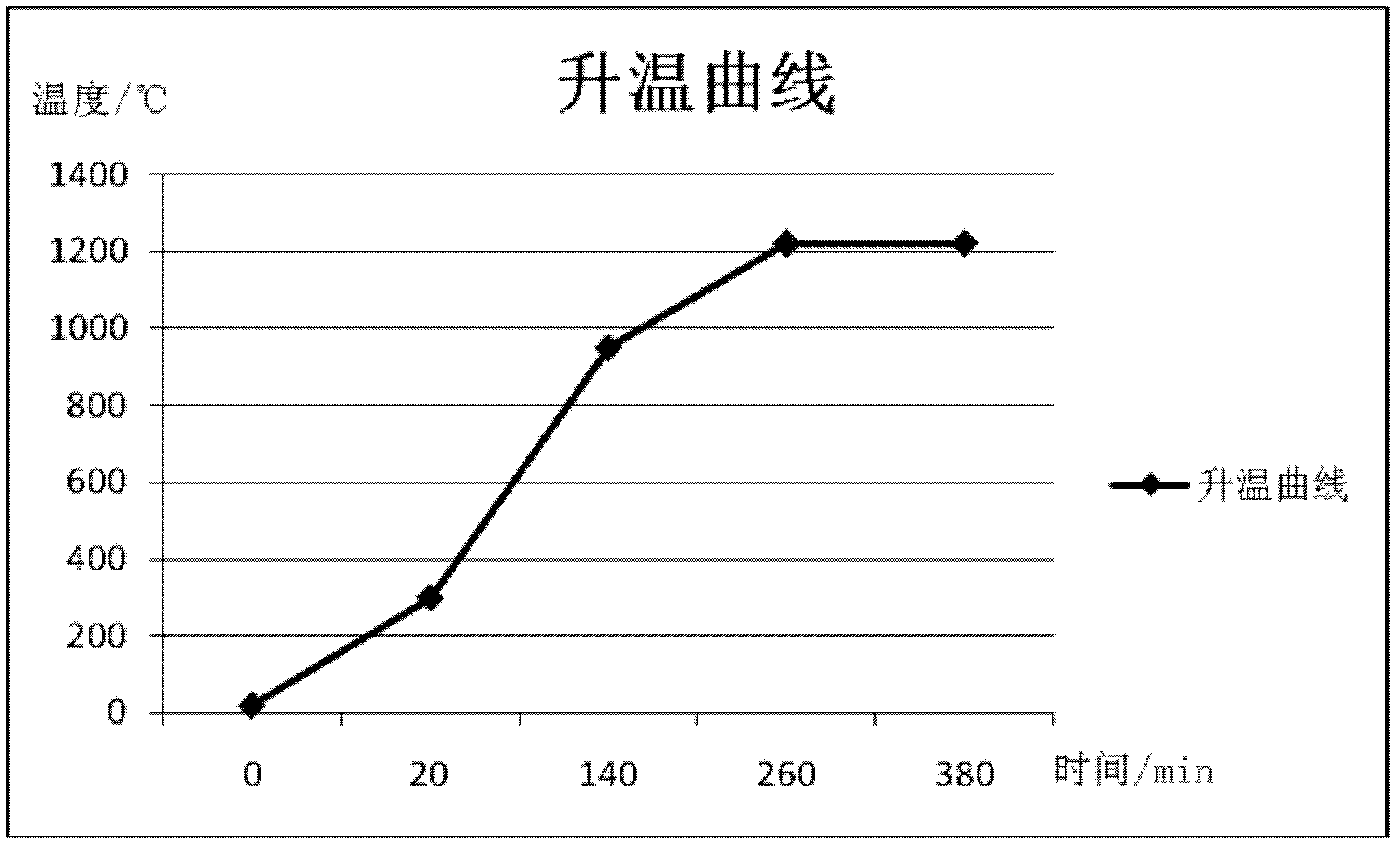

[0063] Mix the spent catalyst with ammonium sulfate at a ratio of 1:0.1, grind it to about 400 mesh, and then put it into a roasting furnace at a heating temperature of 1300°C. At this temperature, heat conversion is carried out. The temperature rise curve for the preparation of the pigment is as follows Figure 4 shown.

[0064] The chromium and cobalt are converted from fluoride to chromium oxide cobalt oxide mixture. The mixture of chromium oxide and cobalt oxide is used as the raw material of ceramics and glass pigments, and the tail gas is discharged after defluorination of lime water.

[0065] 2.2 Preparation of colorant

[0066] Weigh the pulverized chromium oxide cobalt oxide mixture 54%, Al 2 o 3 46%, grind to about 400 mesh, put it into a resistance furnace for firing, the synthesis temper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com