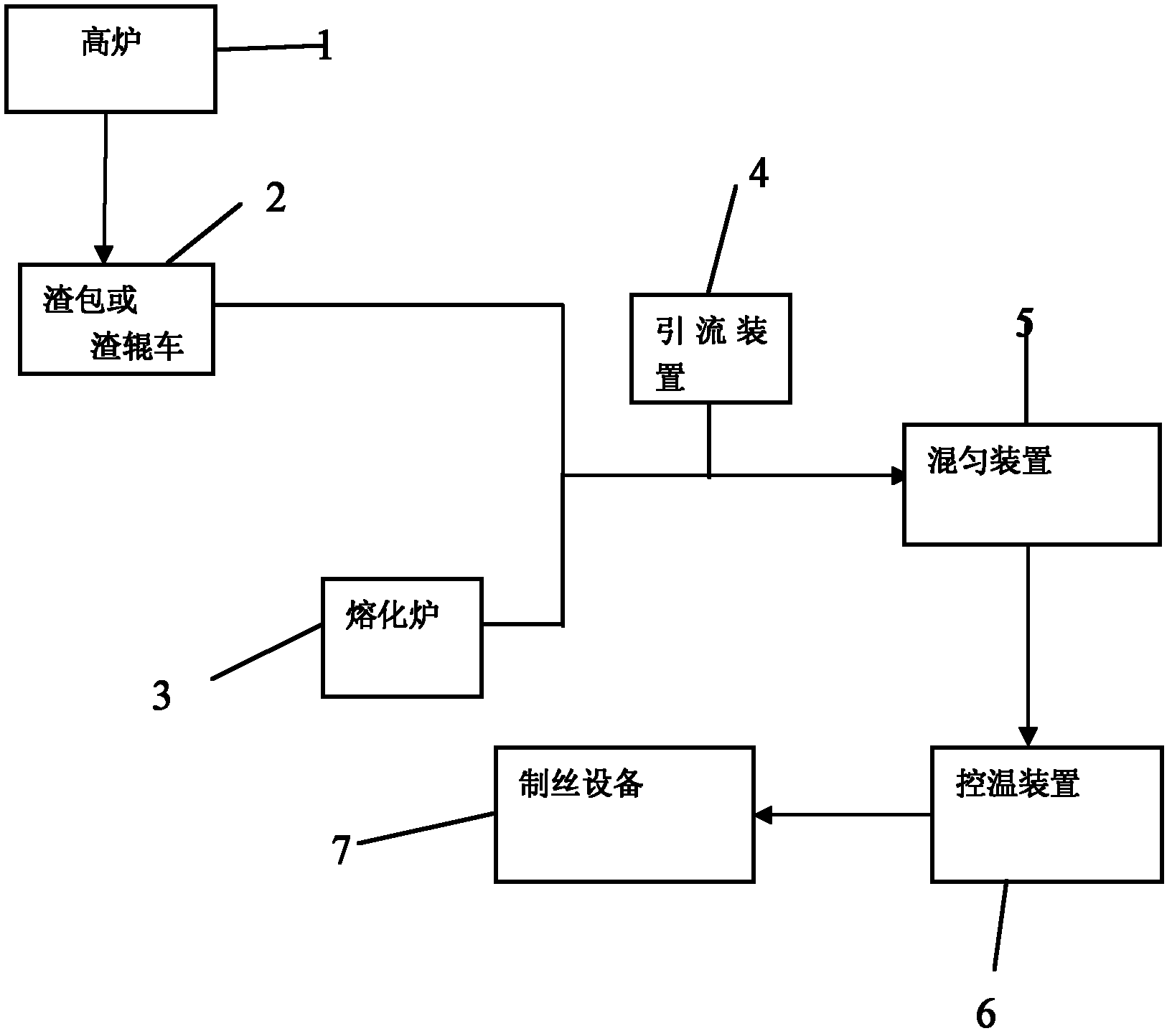

Equipment and method for preparing inorganic slag fiber from hot blast furnace slag

A technology of slag fiber and blast furnace slag, which is applied in the field of preparation of inorganic non-metallic materials, can solve the problems of difficulty in preparing inorganic slag fiber with uniform quality and difficulty in fusion, and achieve the effects of promoting economy and society, wide application, and simple and easy method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

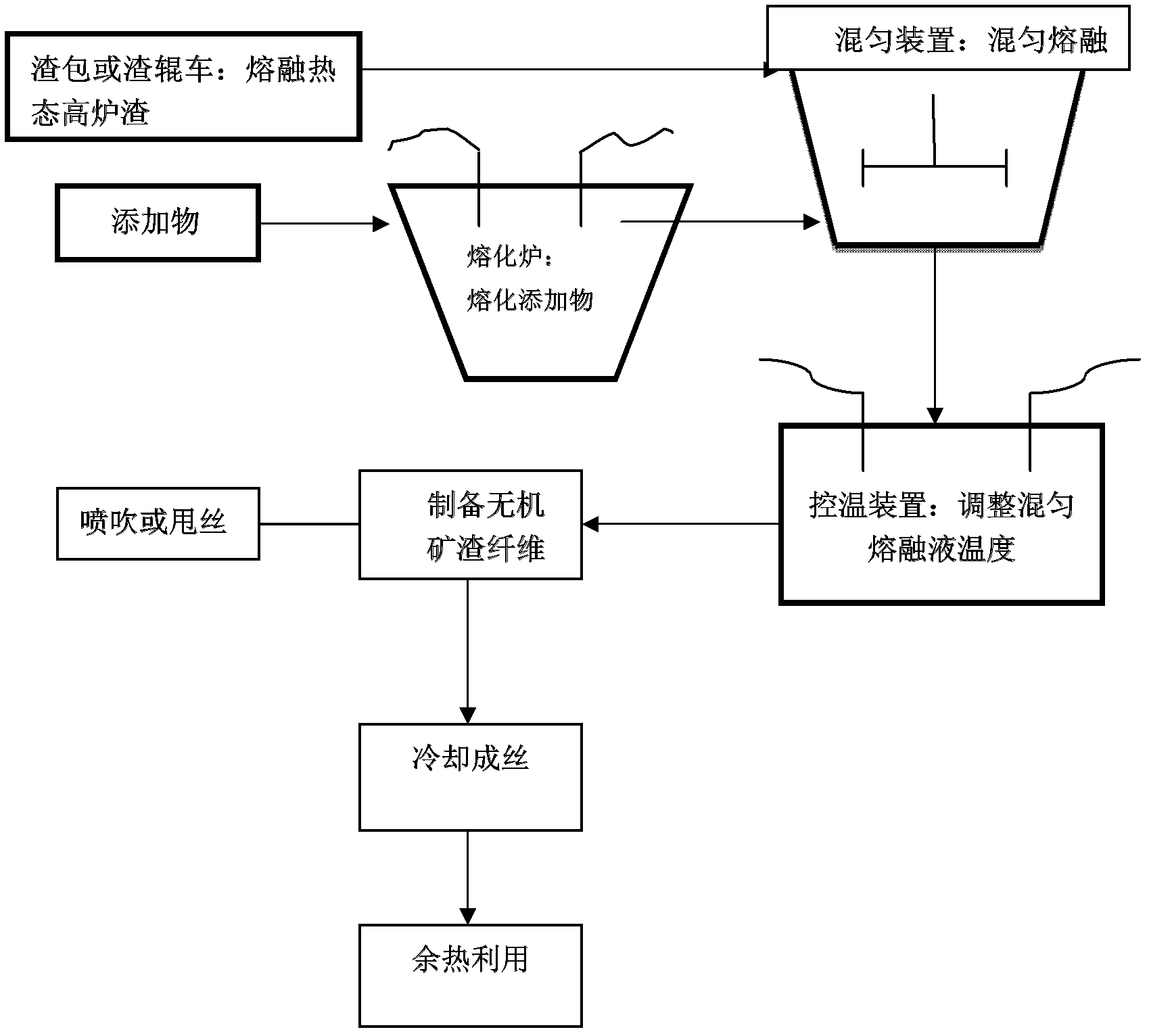

Method used

Image

Examples

Embodiment 1

[0058] The hot blast furnace slag (70% by weight) directly discharged from the slag outlet of the blast furnace 1 is stored through the slag bag 2, and the temperature of the hot blast furnace slag is adjusted to 1450°C. At the same time, the additive fly ash (30% by weight) is added into the melting furnace 3 and heated by a heating element to melt it. Then, the molten hot blast furnace slag in the slag bag 2 and the molten additive fly ash in the melting furnace 3 enter the mixing furnace 5 through the drainage device 4 . In the mixing furnace 5, mixing is carried out by rotating mixing blades in the furnace, so as to obtain a mixed molten liquid as the final raw material for preparing inorganic slag fibers. Finally, the mixed molten liquid is added into the final furnace 6, and the temperature is adjusted to 1500°C. The molten liquid flows into the spinning machine 7, and under the action of the centrifugal force of the spinning roller, inorganic slag fiber filaments of di...

Embodiment 2

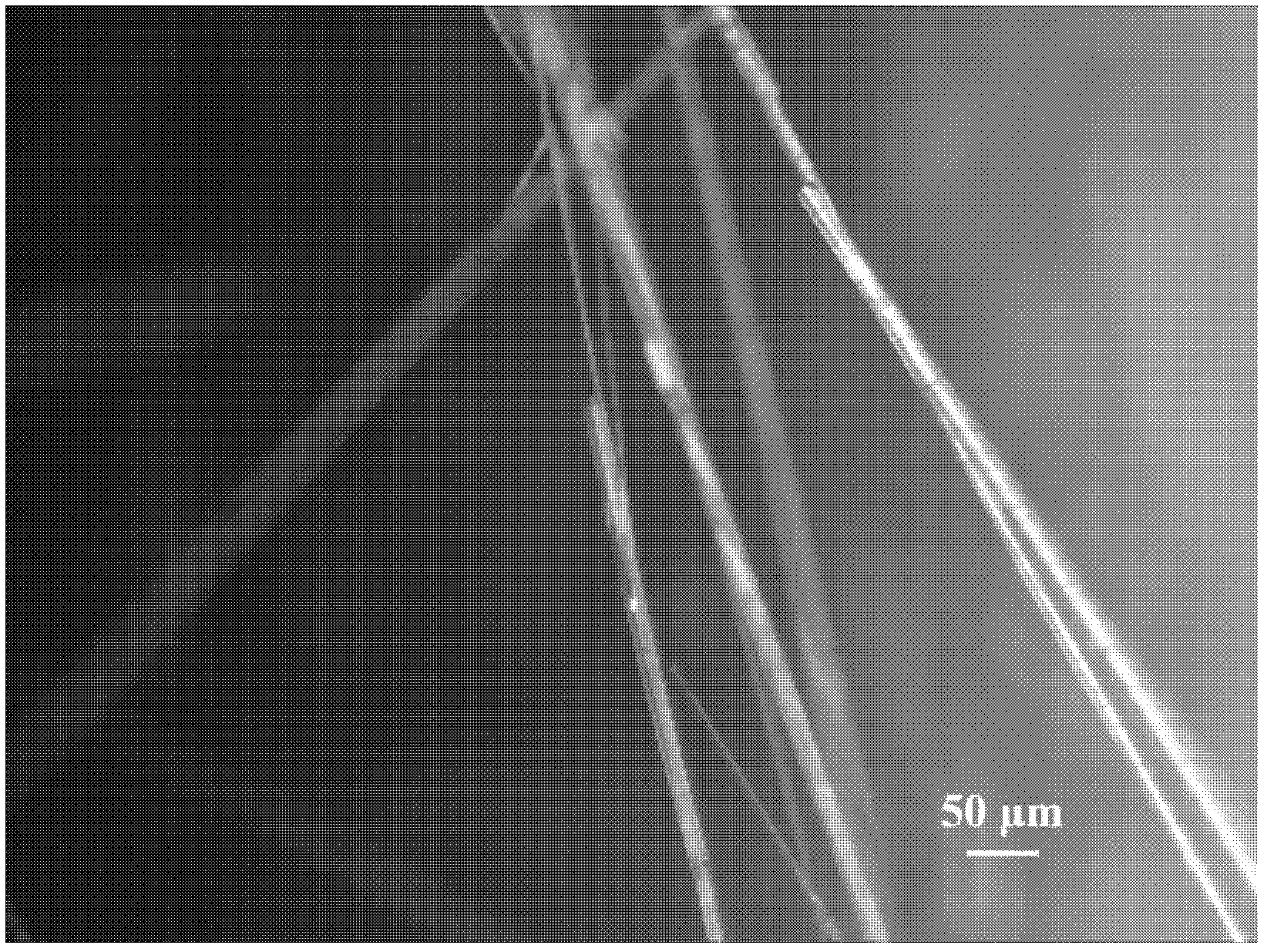

[0060] Using the same preparation method as in Example 1, the difference is that the temperature is adjusted to 1600°C in the final furnace 6, and the finally obtained inorganic slag fiber is as Figure 4 shown. The obtained fibers had an average diameter of 6.1 µm.

Embodiment 3

[0062] Using the same preparation method as in Example 1, the difference is that after the temperature is adjusted to 1700 ° C in the temperature control kettle 6, the molten liquid flow is obtained, and the multi-hole spinneret 7 is used to spray into filaments, and the injection pressure is 1.2 MPa, inorganic slag fibers are obtained after cooling. The obtained fibers had an average diameter of 5.5 µm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com