fire retardant cigarette

A technology for cigarettes and fireproof jackets, which is applied in the fields of tobacco, cigar manufacturing, and application, can solve the problems of changing the taste of cigarettes and the continuous exposure of open flames, and achieve the effect of reducing the ignition rate and smooth smoking.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

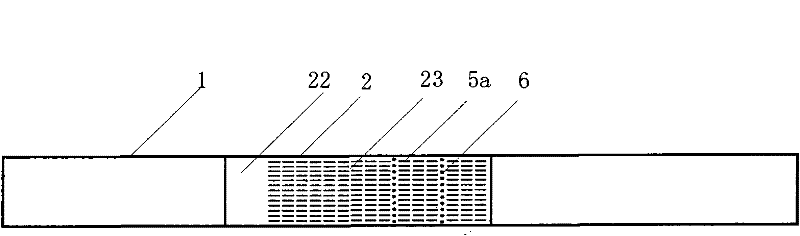

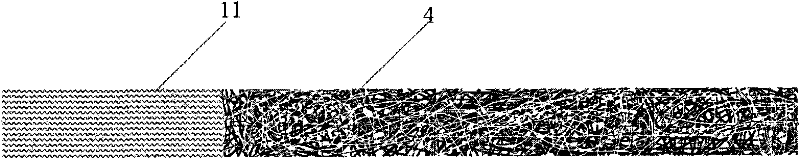

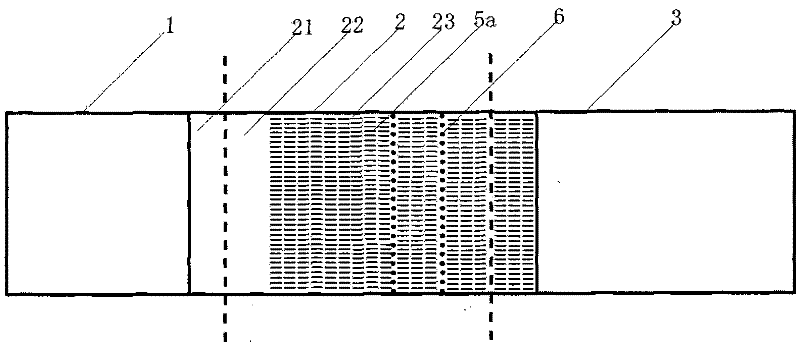

[0042] like figure 1 The schematic diagram of the appearance of the first embodiment of the flame-retardant and fire-resistant cigarette of the present invention, Figure 1a Schematic diagram of the internal structure and Figure 1b As shown in the expanded view of the external structure, the flame-retardant and fire-resistant cigarette of the present invention includes: a filter core 11; a cut tobacco body 4 connected to the filter core 11 ; 2; the filter paper sleeve 1 wrapping the filter core 11 that has been sleeved with the flame-retardant and fireproof sleeve 2; and the cigarette paper sleeve 3 wrapping the other part of the shredded tobacco body 4.

[0043] Wherein, the flame retardant and fireproof cover 2 is a cover body composed of flame retardant materials such as aluminum foil, gold foil, copper foil and the like.

[0044] Among them, such as Figure 1b As shown, the flame-retardant and fire-proof cover 2 is divided into successively: the connecting area 21 for ...

Embodiment 2

[0049] Figure 2 to Figure 2b In order to invent the structure of the second embodiment of the flame-retardant fireproof cigarette.

[0050] like figure 2 The schematic diagram of the appearance of the flame-retardant and fire-resistant cigarette of the second embodiment of the present invention, Figure 2a Schematic diagram of the internal structure of the second embodiment and Figure 1b As shown in the expanded view of the external structure of the second embodiment, the flame-retardant and fire-resistant cigarette of the present invention includes: a filter core body 11; a shredded tobacco body 4 connected to the filter tip core body 11; A fireproof cover 2; a filter paper cover 1 wrapping the filter core 11 that has been sleeved with the fireproof cover 2.

[0051] Other structures of the flame-retardant and fire-resistant cigarette of the second embodiment are the same as those of the first embodiment, and will not be repeated here.

Embodiment 3

[0053] like image 3 It is a schematic diagram of the appearance of the third embodiment of the flame-retardant and fire-resistant cigarette of the present invention, Figure 3a for image 3 Schematic diagram of the internal structure of the flame-retardant and fire-resistant cigarette shown; Figure 3b Yes image 3 Expanded view of the external structure of the flame-retardant and fire-resistant cigarette shown; Figure 3c Yes Figure 3b right side view of Figure 3d Yes image 3 right side view of .

[0054] like image 3 , 3a As shown, the flame retardant and fireproof cigarette of the present embodiment comprises: a filter tip body 11; a shredded tobacco body 4 connected to the shredded tobacco body 11; a flame retardant and fireproof cover 2 that wraps the shredded tobacco body 4 and is socketed on the filter tip body 11; Connect the filter tip paper cover 1 of the filter tip core body 11 of the flame retardant and fireproof cover 2.

[0055] Among them, such as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com