Preparation method of bottled mineral water for drinking

A mineral water and filling technology, which is applied in the field of preparation of filled drinking mineral water, can solve the problems of being easily polluted, damaging the trace elements of mineral water, and consumers cannot drink directly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the object, technical solution and technical effect of the present invention clearer, the present invention will be further described below in conjunction with specific embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

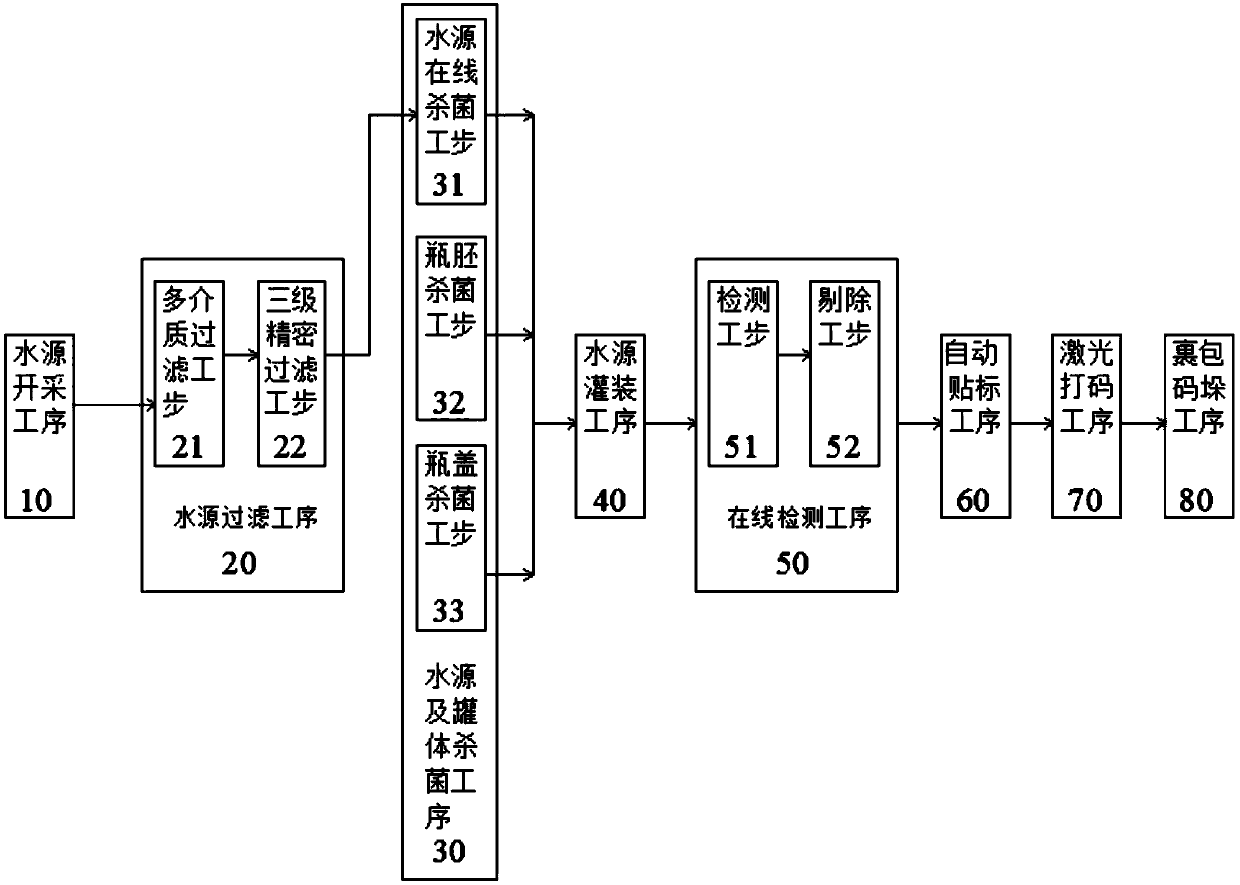

[0019] refer to figure 1 Shown, a kind of preparation method of bottled drinking mineral water, its production technological process is: natural mineral water carries out water source mining through water source exploitation process 10 successively, and then passes through described multi-media filtration step 21 and described three-stage precision filtration Filtration in process step 22, the filtered water source is sterilized by water source on-line sterilization process step 31 and at the same time the preform and bottle cap for filling are sterilized by the preform sterilization process step 32 and bottle cap steriliz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com