Rapid analysis method for sodium hydroxide and ammonia content in sodium cyanide reaction solution and its liquid products

A technology of sodium hydroxide and liquid products, which is applied in the direction of chemical analysis by titration method, can solve the problems of difficulty in accurate detection of sodium cyanide production control products, quality and safety accidents, hysteresis of hydrochloric acid reaction, etc., and achieve great reference and promotion value, prevention of safety and quality accidents, and ease of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] 1. Test samples

[0028] Randomly select 3 liquid sodium cyanide reaction solutions and 3 liquid sodium cyanide products as test samples, and detect the sodium cyanide content in each sample according to the GB19306-2003 regulations, so as to distinguish them.

[0029] Table 1: Test sample table

[0030]

[0031] 2. Detection process

[0032] (1) Use the national standard acid-base method and national standard silver method to detect the content of sodium hydroxide and ammonia in each sample

[0033] ① Preparation of sample solution (GB 19306-2003)

[0034] Weigh 8 g of sample 1 (about 7.5 ml), accurate to 0.0002 g. Put it in a beaker, dissolve it with water, transfer it all into a 500ml volumetric flask, add water to the mark, and shake well to obtain a sample solution.

[0035] ② Analysis of sodium cyanide content (GB 19306-2003):

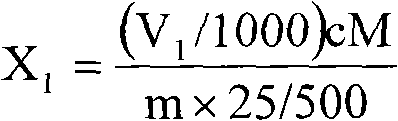

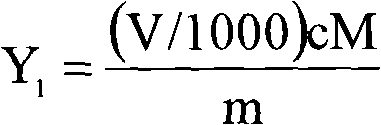

[0036] Use a pipette to pipette 25ml of the sample solution, place it in a conical flask, add 75ml of water and 6-8 drops of dime...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com