High performance thermoplastic elastomer and its application

A thermoplastic elastomer, high-performance technology, applied in the field of styrene-based thermoplastic elastomer and its production, high-performance thermoplastic elastomer, can solve the problems of complex molding process, expensive polyurethane, low elastic coefficient of polyurethane foam, etc. Achieve the effects of simple operation process and process, convenient industrial production, and flexible design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

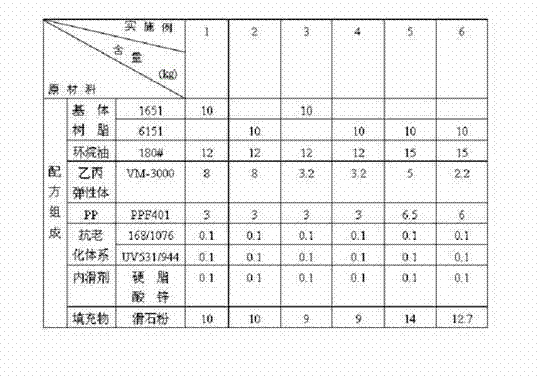

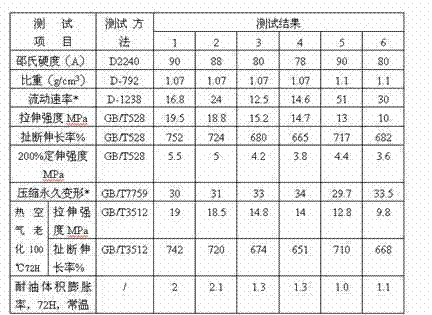

[0015] Embodiment: a kind of high-performance thermoplastic elastomer original, comprises following components and proportioning sees the table below:

[0016] The matrix resin in the raw materials in the table can also be replaced by other high molecular weight SEBS, such as Kuraray's 4055;

[0017] Mineral oil 180# can be replaced by other naphthenic oils with a flash point higher than 200°C, such as KN6008;

[0018] Homopolymer PP can be replaced by other extrusion grade PP with low melting point and high tensile strength, such as T30S;

[0019] Ethylene-propylene elastomer VM-3000 can be replaced by other ethylene-propylene elastomers such as VM-3001;

[0020] The anti-aging system can be replaced by at least two or all combinations of similar antioxidant 168, antioxidant 1076, anti-ultraviolet agent 944, and anti-ultraviolet agent uv-531;

[0021] The mineral filler is one or a mixture of calcium carbonate, talc, clay, barium sulfate, mica powder, kaolin, wollastonite, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Flash point | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com