Manufacturing process of railway signal cables

A manufacturing process and railway signal technology, which is applied in the direction of manufacturing tools, arc welding equipment, metal processing equipment, etc., can solve problems affecting the welding quality of aluminum sheaths, etc., and achieve improved compactness, strong crack resistance, and small deformation of weldments Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

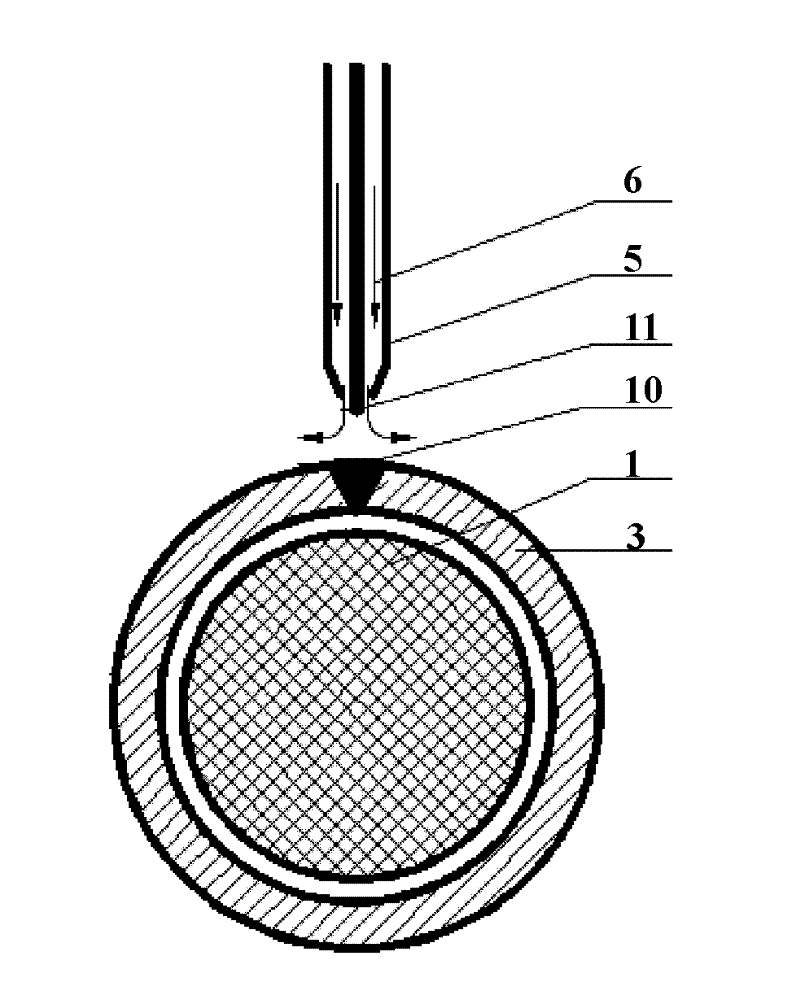

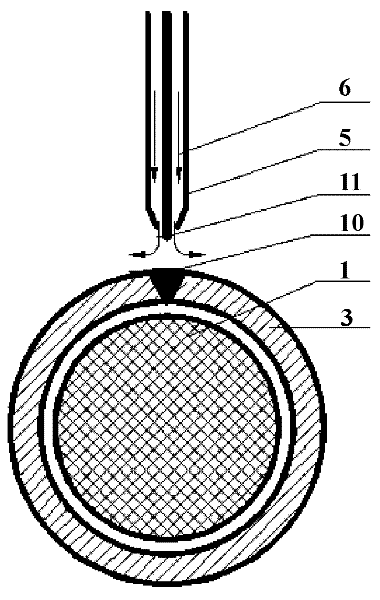

[0028] Example: A manufacturing process for railway signal cables. The welding of the aluminum sheath of the cable adopts non-melting electrode argon arc welding technology. Its working principle and characteristics are: the arc is at the non-melting electrode, namely the tungsten electrode 11 and the workpiece (Cable aluminum sheath) burns, and an inert gas (usually argon) that does not react with the metal flows around the welding arc to form a protective gas shield, making the tip of the tungsten electrode 11 and the arc It is not in contact with the molten pool and the aluminum sheath of the cable at high temperature, which can prevent the aluminum sheath of the cable from oxidizing and absorbing harmful gases, thereby forming a dense welding seam.

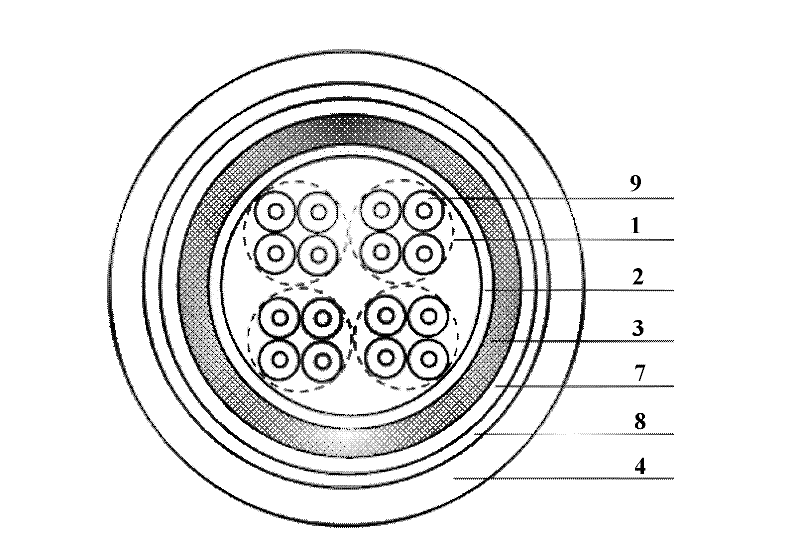

[0029] The cable includes a cable core 1, a cable core wrapping layer 2, an aluminum sheath layer 3 and an outer sheath layer 4 wrapped around the cable core wrapping layer 2, and the aluminum sheath layer 3 is made of electrical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com