Measuring method and electronic measuring device for oil-water content in oil storage tank

A technology of oil-water content and measurement method, which is applied to the measurement of crude oil water content, oil-water content in oil storage tanks, and oil-water interface fields. It can solve the problem of not taking into account the influence of temperature, oil-water density, unfavorable fire and explosion-proof safety of oil tank areas, and increase measurement Equipment installation openings and other problems, to achieve the effect of simple structure, low cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

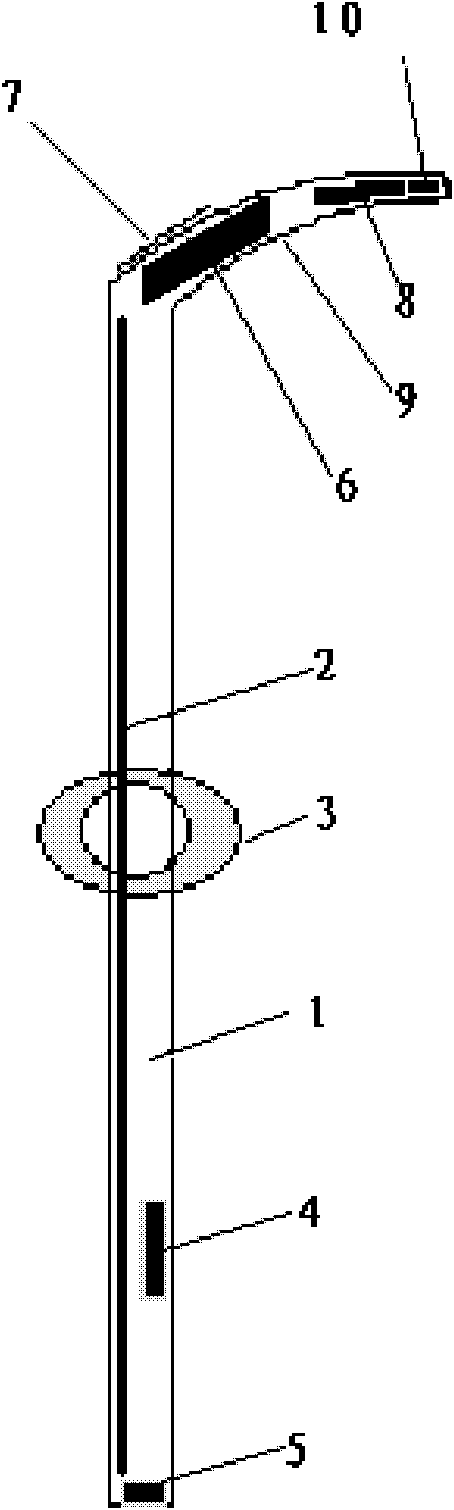

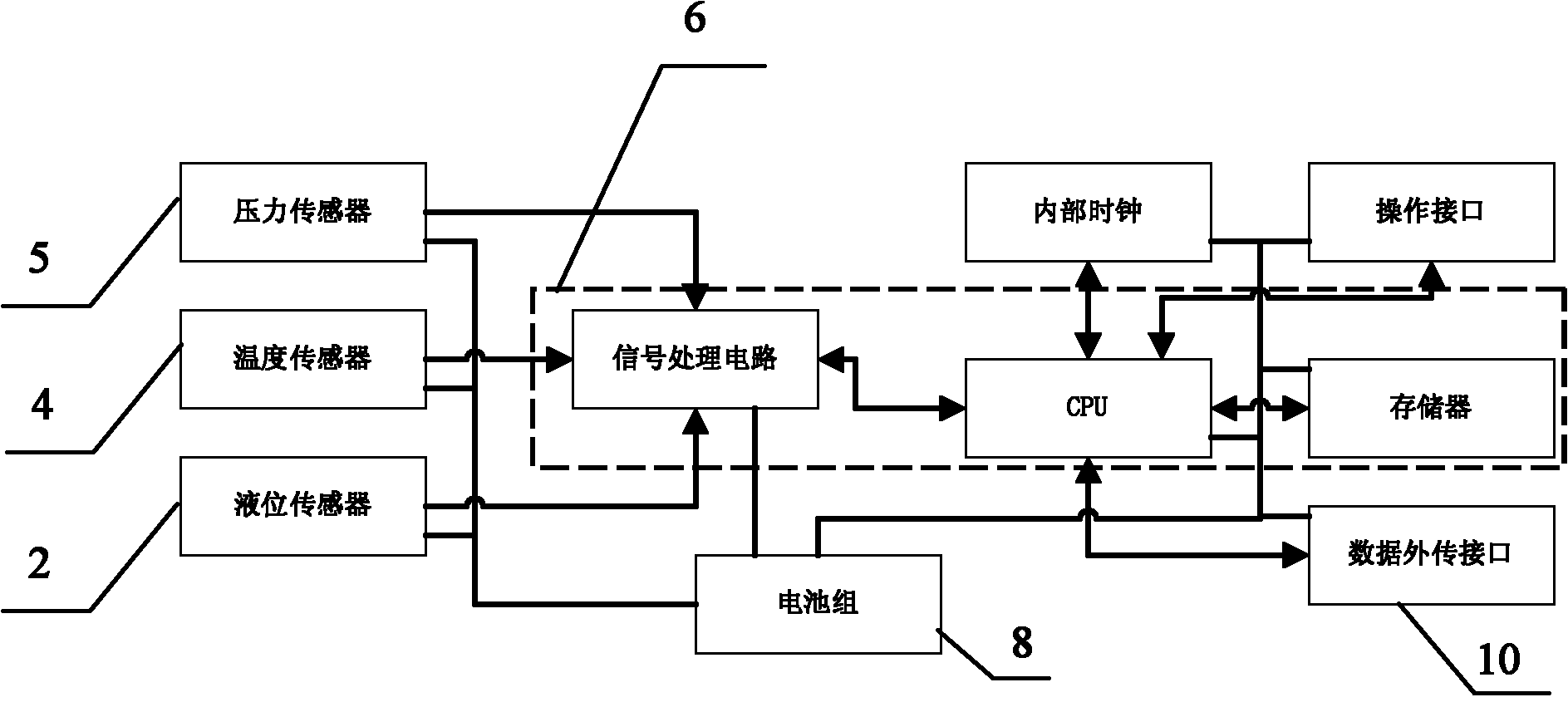

[0044] The implementation of the present invention will be described in detail below in conjunction with the drawings and examples.

[0045] Such as figure 2 Shown, the method for measuring oil-water content in the oil storage tank of the present invention comprises the following steps

[0046] The first step is to measure the liquid level height H in the oil storage tank, the pressure P at the bottom of the oil storage tank, and the temperature T in the oil storage tank;

[0047] In the second step, according to the temperature T in the oil storage tank, use the look-up table method to obtain the temperature-compensated water density ρ 水 and the compensated oil density ρ 油 ; the density of water ρ 水 According to the empirical formula of IFC97 for compensation calculation, the density of oil ρ 油 It is necessary to perform compensation calculations based on the temperature-density relationship data table obtained by the test method;

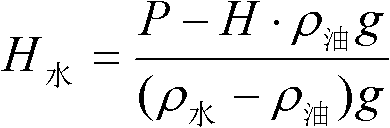

[0048] The third step is to convert t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com