Yarns with non-uniform fiber distribution, fabric and preparation method thereof

A yarn and uniform technology is applied in the field of fabrics with uneven fiber distribution and its preparation, which can solve the problems of unsuitable large-scale continuous production, uneven formation, rough and not delicate surface texture of yarn-dyed fabrics, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

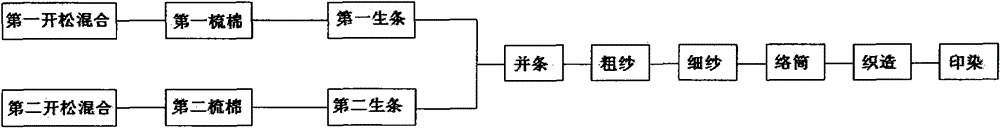

[0071] A method for preparing a yarn with uneven fiber distribution, comprising the steps of:

[0072] (1) First opening and mixing

[0073] Make one pile of polyester fibers and another pile of cellulose fibers, and arrange the two piles of fibers on the plucking machine for opening and mixing;

[0074] The polyester fiber accounts for 30-60% by weight of the finished yarn, and the cellulose fiber accounts for 10-30% by weight of the finished yarn.

[0075] In the first opening and mixing step of the present invention, the plucking machine may be a disc plucking machine or an in-line plucking machine.

[0076] Taking the disc plucking machine as an example,

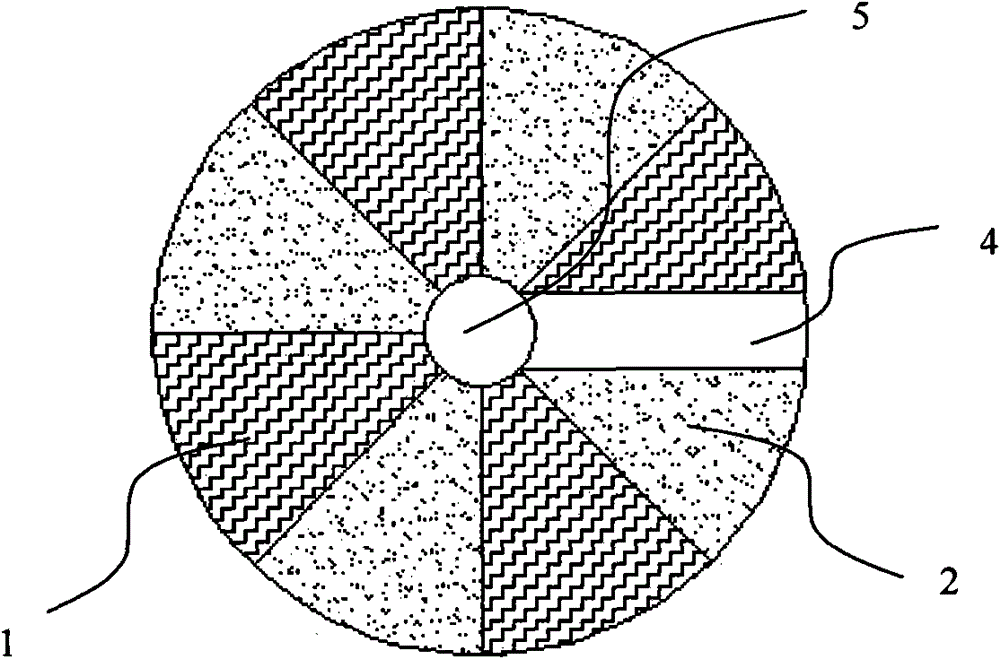

[0077] In the prior art, the arrangement and distribution of the raw materials of the disc bale machine in the opening and mixing step is as follows: figure 2 shown. The feeding of polyester fiber 1 and cellulose fiber 2 is evenly arranged in the disc catching machine, and the polyester fiber 1 and cellulose fiber 2...

Embodiment 1

[0116] A method for preparing a fabric with non-uniform fiber distribution, its process flow chart can be found in figure 1 . Specifically include the following steps:

[0117] (1) First opening and mixing

[0118] Make one pile of polyester fibers and another pile of cellulose fibers, and arrange the two piles of fibers on the plucking machine for opening and mixing;

[0119] The polyester fiber accounts for 30% by weight of the finished yarn, and the viscose fiber accounts for 10% by weight of the finished yarn.

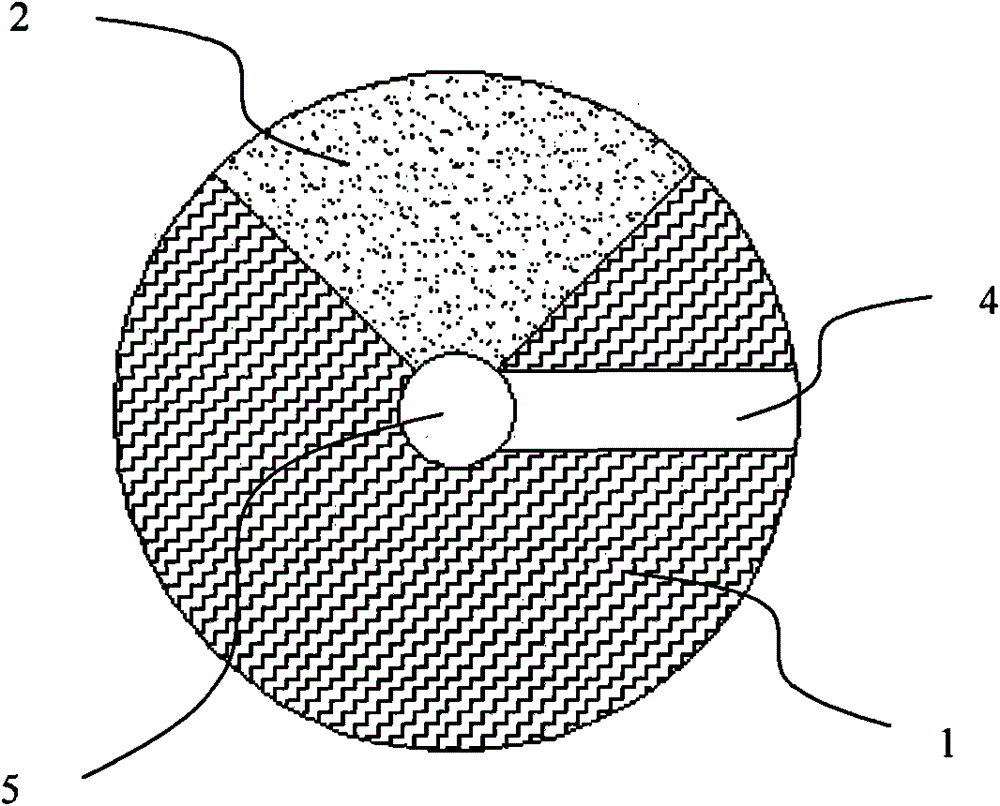

[0120] The arrangement and distribution of the raw materials of the disc bale machine in the first opening and mixing step is as follows: image 3 shown. The feeding of polyester fiber 1 and cellulose fiber 2 in the disc catching machine is unevenly arranged, and the distribution of polyester fiber 1 and cellulose fiber 2 is unevenly distributed at large intervals. The rotating shaft 4 of the disc catching cotton machine rotates vertically, and at the same tim...

Embodiment 2

[0166] A method for preparing a fabric with non-uniform fiber distribution, its process flow chart can be found in figure 1 . Specifically include the following steps:

[0167] (1) First opening and mixing

[0168] The polyester fibers and cellulose fibers are arranged unevenly on the in-line plucking machine. The specific method is: the polyester fiber is one pile, the cellulose fiber is another pile, and the two piles of fibers are arranged on the cotton plucking machine. Then carry out loosening and mixing;

[0169] The polyester fiber accounts for 60% by weight of the finished yarn, and the viscose fiber accounts for 30% by weight of the finished yarn.

[0170] The arrangement and distribution of the raw materials of the in-line plucking machine are as follows: Figure 5 shown. The in-line plucking machine is unevenly arranged for the feeding of polyester fiber 1 and cellulose fiber 2, and the distribution of polyester fiber 1 and cellulose fiber 2 is uneven and large...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com