A kind of preparation method of milk thistle oil

A technology of milk thistle oil and milk thistle, applied in the field of milk thistle oil extraction and extraction of milk thistle oil, can solve the problems of low extraction rate of milk thistle oil, high impurity moisture content, low production efficiency, etc. The effect of shortening the operation cycle, improving the extraction efficiency and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

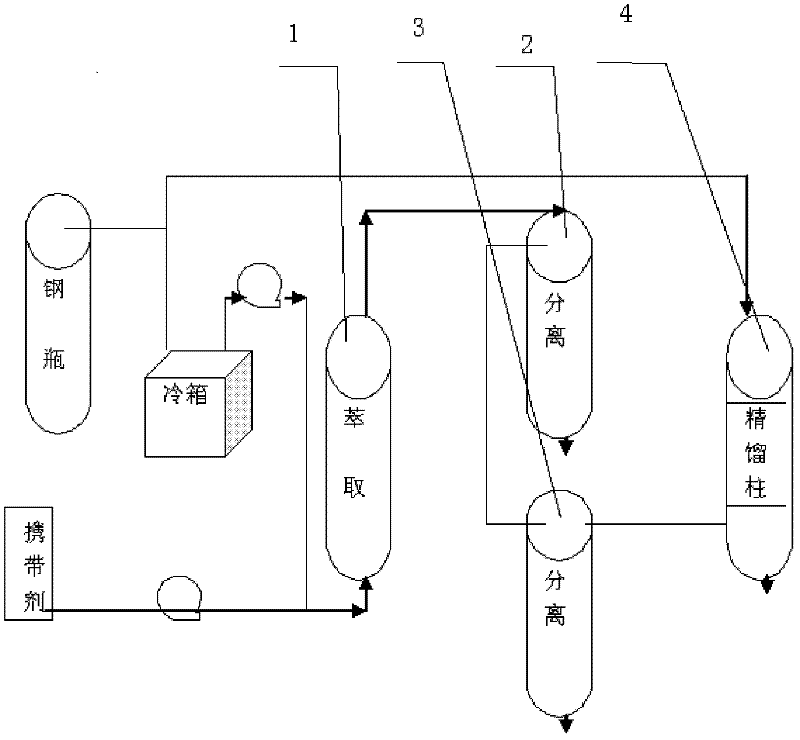

[0028] A preparation method of milk thistle oil, which comprises weighing 9 kg of milk thistle seeds, breaking the wall purely at room temperature to obtain a fine powder of 100 mesh, and then carrying out physical property wet granulation with alcohol with a mass concentration percentage of 80-85% to obtain a particle size 16 mesh, the particles are filled in the extraction kettle 1, the supercritical CO2 fluid is introduced, the extraction pressure is 28Mpa, the extraction temperature is 42°C, CO 2 Extract for 1 hour under the condition of fluidization volume 400L / hr; then feed 95% edible ethanol 720g as carrier, and extract for 1 hour; CO2 with silymarin oil 2 The gas flows into the separation tank for secondary separation. The separation pressure of the primary separation tank 2 is 8Mpa and the temperature is 35°C; the separation pressure in the secondary separation tank 3 is 5Mpa and the temperature is 30°C; the separated milk thistle oil enters the rectification Column 4...

Embodiment 2

[0031] A preparation method of milk thistle oil, which comprises weighing 9kg of milk thistle seed powder, breaking the wall purely physically at room temperature to obtain a fine powder of 160 mesh, and then carrying out physical property wet granulation with alcohol with a mass concentration percentage of 80-85% to make granules The density is 18 mesh, the particles are filled in the extraction kettle 1, the supercritical CO2 fluid and the carrier are introduced, the extraction pressure is 32Mpa, the extraction temperature is 55°C, and the CO 2 Extract for 1 hour under the condition of fluidization volume 400L / hr; then feed 720g of edible ethanol with a mass concentration percentage of 95% as a carrier, and extract for another hour; the CO with milk thistle oil 2 The gas flows into the separation tank for secondary separation. The separation pressure of the first separation tank 2 is 10Mpa and the temperature is 35°C; the separation pressure of the second separation tank 2 is...

Embodiment 3

[0034]A preparation method of milk thistle oil, which comprises weighing 9kg of milk thistle seed powder, breaking the wall purely physically at room temperature to obtain a fine powder of 100 mesh, and then carrying out physical property wet granulation with alcohol with a mass concentration percentage of 80-85% to make granules The degree is 16 mesh, and the particles are fully mixed with the filler (wheat bran or rice husk) and then filled in the extraction kettle 1. The mixing ratio is milk thistle seed particles: wheat bran or rice husk=10:1, calculated by weight ratio; Introduce supercritical CO2 fluid and carrier, extraction pressure 28Mpa, extraction temperature 42°C, CO 2 Extract for 1 hour under the condition of fluidization volume 400L / hr; then feed the mass concentration percentage and be 95% edible ethanol 720g as carrier, and extract for 1 hour; the CO with milk thistle oil 2 The gas flows into the separation tank for secondary separation. The separation pressure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com