A method for purifying withaferin a

A technology of withaferin and macroporous resin, which is applied in the field of natural medicinal chemistry, can solve the problems of silica gel column separation sample loss, easy emulsification of extraction solvent, and difficult quantitative production, etc., to overcome dead adsorption of samples, large amount of preparation, and simple operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

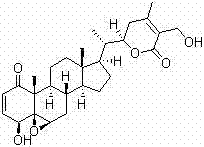

Image

Examples

Embodiment 1

[0014] The raw material of Indian ginseng is crushed, 2kg is added to the ultrasonic extraction tank, 10 times the amount of 90% methanol is added for ultrasonic extraction, the power is 2kw, the frequency is 40kHz, the extraction is 30min, the liquid is filtered, and 6 times the amount of methanol is added for 30min, and the two extractions are combined The liquid is decompressed to recover methanol, add appropriate amount of water to disperse, add 300g HZ816 macroporous resin for adsorption, first take 1.2L of 60% methanol solution to elute impurities, and then use 1.5L of 90% methanol solution to elute, collect the eluate and concentrate to obtain paste. Mix chloroform, methanol, and water in a ratio of 5:5:3, let stand to separate layers, take the upper phase and inject it into a high-speed countercurrent chromatographic column, turn on the high-speed countercurrent chromatograph, adjust the rotation speed to 900rpm, and pump it into the lower phase at a flow rate of 6ml / mi...

Embodiment 2

[0016] Indian ginseng raw material is crushed, take 2kg and put it into the ultrasonic extraction tank, add 8 times the amount of 80% methanol for ultrasonic extraction, turn on the power 2kw, frequency 640kHz, extract for 30min, extract twice, combine the extracts to recover methanol under reduced pressure, add appropriate amount of water, add Adsorb in 300gHZ816 macroporous resin, first take 1.5L of 40% methanol solution to elute impurities, and then use 1.52L of 99% methanol solution to elute, collect and concentrate the eluate to obtain extract. Take chloroform, methanol, and water and mix them in a ratio of 4:3:2, let them stand for stratification, take the upper phase and inject it into a high-speed countercurrent chromatography column, turn on the high-speed countercurrent chromatography, adjust the rotation speed to 700rpm, and pump it into the lower phase at a flow rate of 8ml / min at the same time. After the whole system is dynamically balanced, the flow rate of the mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com