Preparation method of composite nanometer particulate anodyne

A technology of composite nanoparticles and analgesics, which is applied in the field of preparation of drug-loaded nanoparticles, can solve the problems of easy occurrence of gastrointestinal adverse reactions, restrict clinical application, etc. effective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

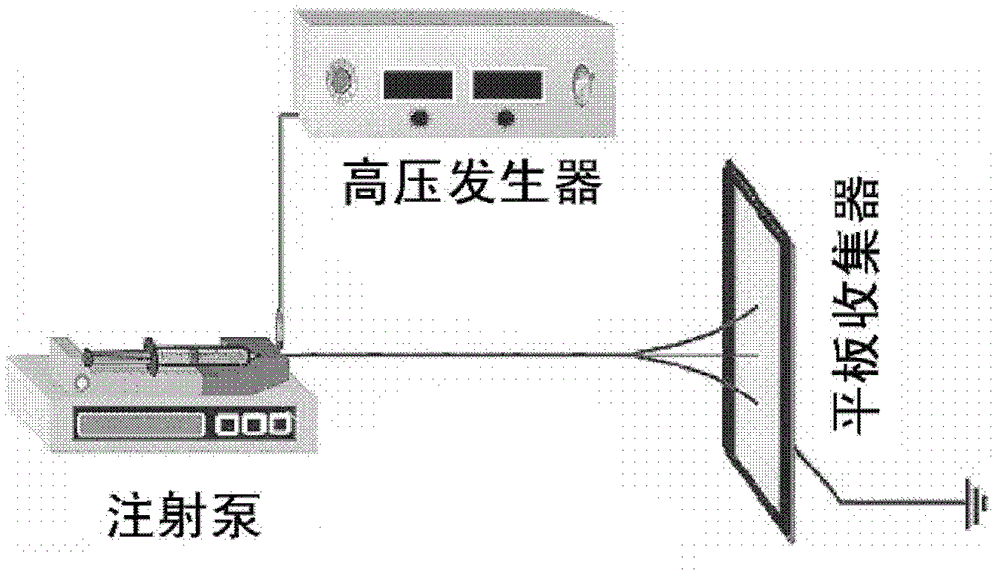

Method used

Image

Examples

Embodiment 1

[0025] Suspend 6g of ketoprofen in 50mL of ethanol, and gradually add 6g of ethyl cellulose during heating and rapid stirring to form a suspension (the mass ratio of ketoprofen to ethyl cellulose is 1:1) .

[0026] Pour the above solution into the solution reservoir (5mL syringe), use a flattened No. 9 injection needle as the capillary for jetting thin stream, connect the positive electrode of the high-voltage power supply, first use the aluminum foil receiving plate with the glass slide as the negative electrode, accept Electrospray particles for 10 minutes for polarizing microscope observation, and then use an aluminum foil receiving plate to connect the negative electrode to receive electrospray particles.

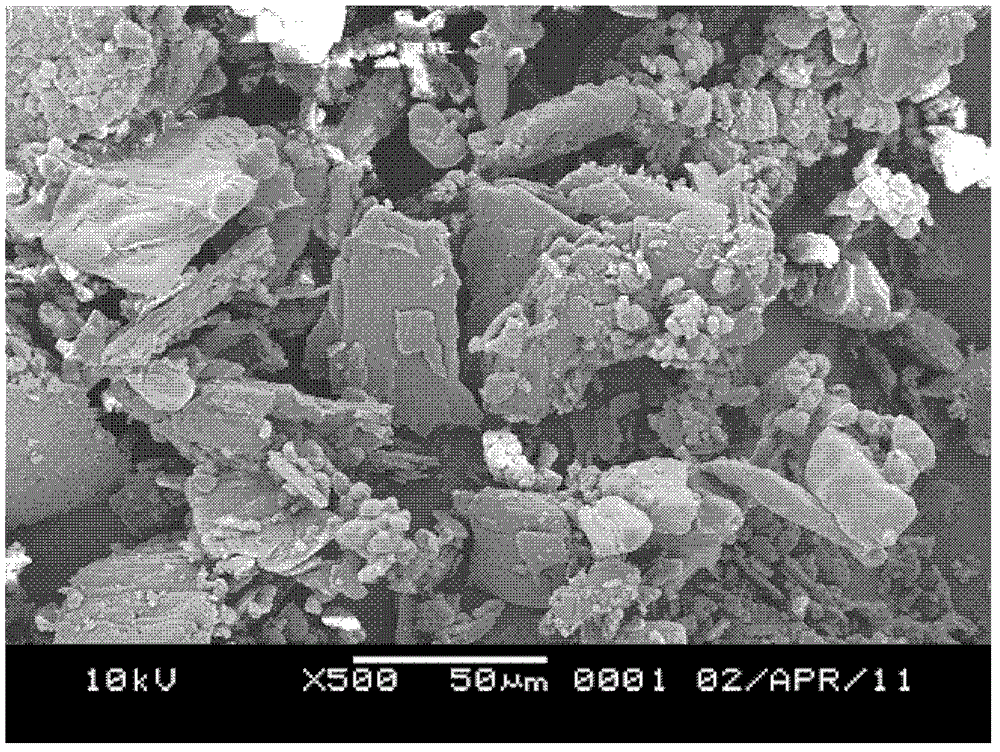

[0027] EFI process conditions: flow rate is 1.5mL h -1 , the distance between the receiving plate and the electrospray is 10cm, the voltage is 15kV, the ambient temperature is 20°C, and the ambient humidity is 65%. After the solution in the syringe is electrosprayed, r...

Embodiment 2

[0030] Suspend 3g of ketoprofen in 50mL of ethanol, during heating and rapid stirring, gradually add 6g of ethyl cellulose to form a suspension (the mass ratio of ketoprofen to ethyl cellulose is 1:2) .

[0031] Pour the above solution into the solution reservoir (5mL syringe), use a flattened No. 9 injection needle as the capillary for jetting thin stream, connect the positive electrode of the high-voltage power supply, first use the aluminum foil receiving plate with the glass slide as the negative electrode, accept Electrospray particles for 10 minutes for polarizing microscope observation, and then use an aluminum foil receiving plate to connect the negative electrode to receive electrospray particles.

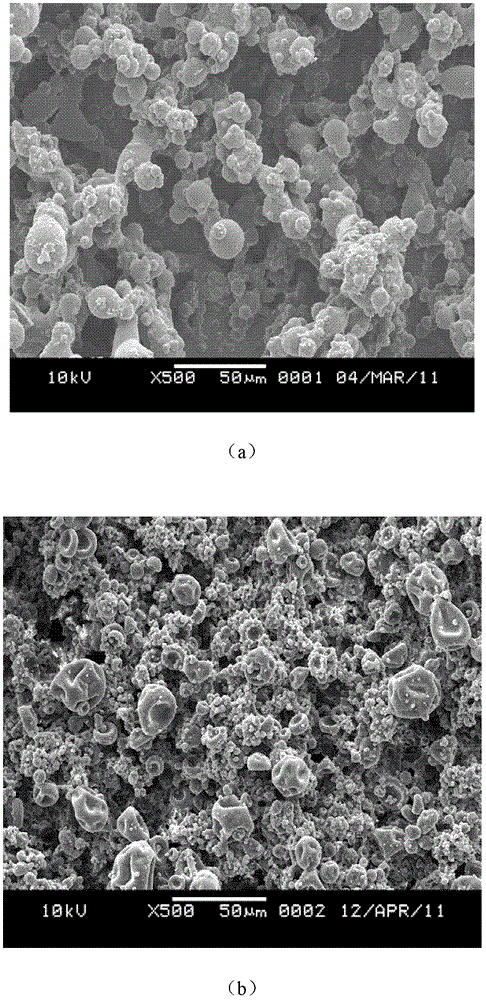

[0032] EFI process conditions: flow rate is 2.0mL h -1 , the distance between the receiving plate and the electrospray is 20cm, the voltage is 20kV, the ambient temperature is 19°C, and the ambient humidity is 70%. After the solution in the syringe is electrosprayed, remo...

Embodiment 3

[0035] 1.5g ketoprofen is suspended in 50mL ethanol, in heating and rapid stirring process, gradually add ethyl cellulose 6g, be made into suspending solution (the mass ratio of ketoprofen and ethyl cellulose is 1: 4 ).

[0036] Pour the above solution into the solution reservoir (5mL syringe), use a flattened No. 9 injection needle as the capillary for jetting thin stream, connect the positive electrode of the high-voltage power supply, first use the aluminum foil receiving plate with the glass slide as the negative electrode, accept Electrospray particles for 10 minutes for polarizing microscope observation, and then use an aluminum foil receiving plate to connect the negative electrode to receive electrospray particles.

[0037] EFI process conditions: flow rate is 1.8mL h -1 , the distance between the receiving plate and the electrospray is 15cm, the voltage is 16kV, the ambient temperature is 21°C, and the ambient humidity is 60%. After the electrospraying of the solutio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com