Brake device lubrication device and method for controlling same

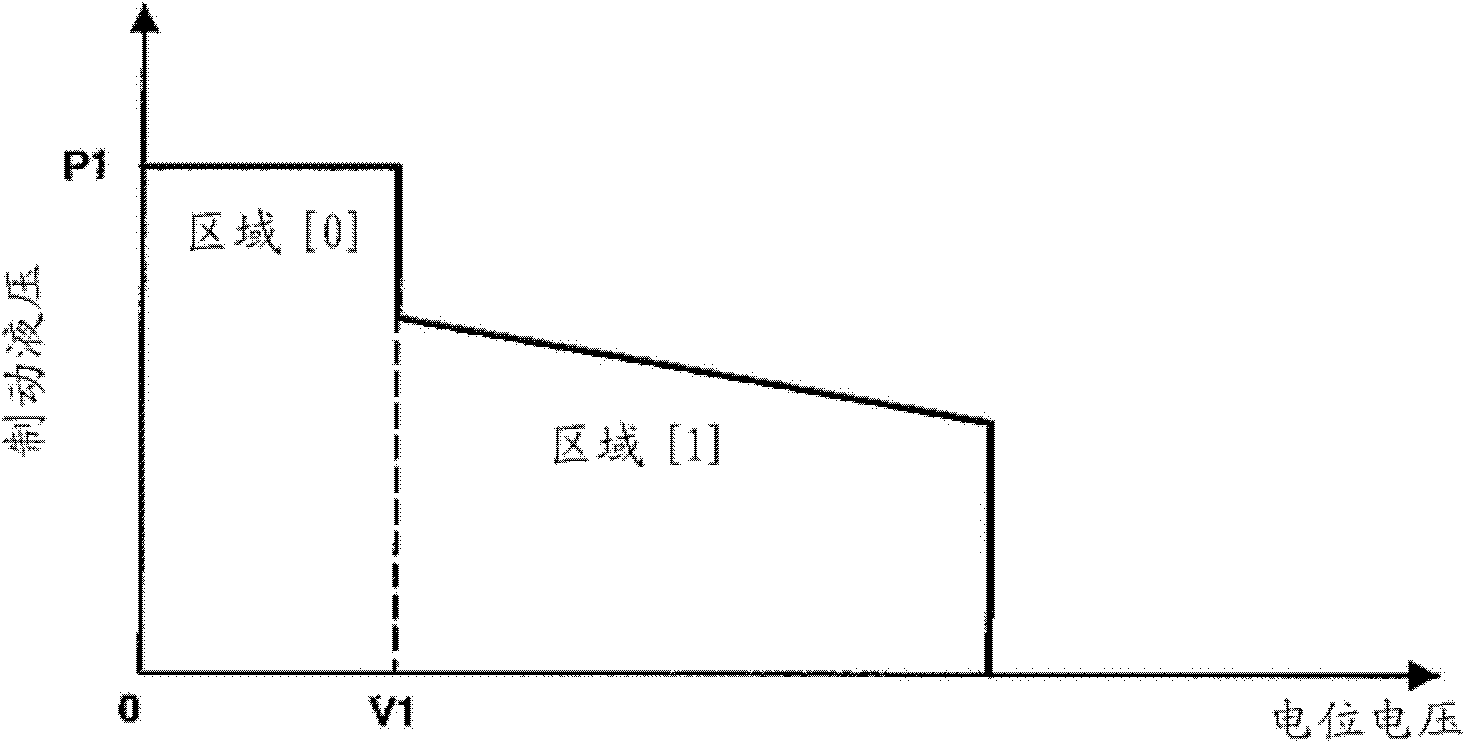

一种制动装置、润滑装置的技术,应用在制动器的部件、制动器、冷却制动器等方向,能够解决降低抑制驱动力损耗的效果、润滑油供给量下降、旋转构件过热等问题,达到抑制过热、抑制损耗、抑制的产生的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] 〔constitute〕

[0041] figure 1 A schematic configuration diagram showing a system of a work vehicle 1 having a lubricating device according to an embodiment of the present invention. This work vehicle 1 is, for example, a bulldozer, and includes an engine 2, a power transmission mechanism 3, a pair of travel devices 4a, 4b, a lubricating oil supply unit 6, various operation units 32 to 35, a control unit 7, and the like. Among these components, the lubricating oil supply unit 6 and the control unit 7 constitute a lubricating device that supplies cooling lubricating oil to the brake devices 5a and 5b. The details of the various operation units 32 to 35 will be described later.

[0042] The engine 2 is a diesel engine, and the output of the engine 2 is controlled by adjusting the fuel injection amount from a fuel injection pump (not shown). Specifically, the engine speed and the fuel injection amount are adjusted according to the load so that the actual engine speed re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com