Die peeling device with safety push-up pin

A technology for stripping devices and chips, which is applied in the manufacture of electrical components, circuits, semiconductors/solid-state devices, etc. It can solve the problems of mass production loss, reliability and productivity decline, and product productivity reduction in the IC packaging industry, and reduce needle replacement. Auxiliary process time, prevent splinters, easy to observe the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

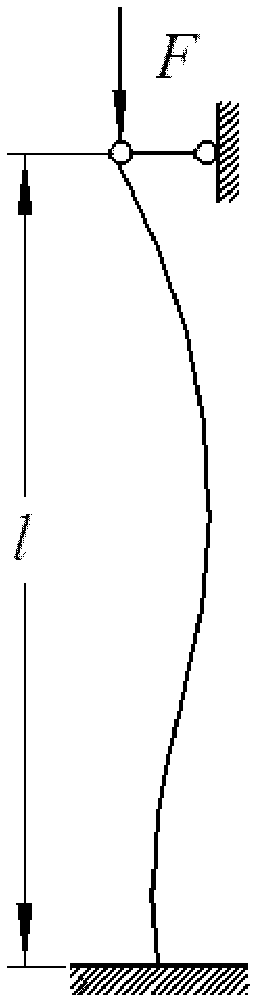

[0048] The invention is applied to the peeling off of the chip and the sticky film in the process of IC packaging such as Flip Chip upside-down packaging, and the device includes a sleeve, a safety thimble and an adjustment mechanism.

[0049] The die-bonding film is placed on one end surface of the sleeve and fixed by vacuum adsorption, and the chips to be peeled off are adhered to the die-bonding film.

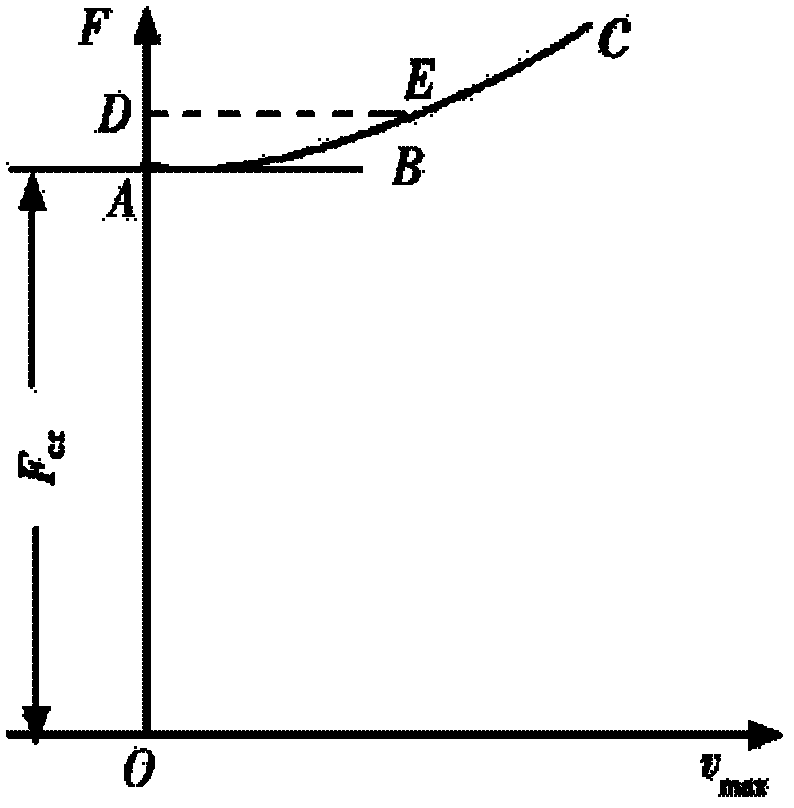

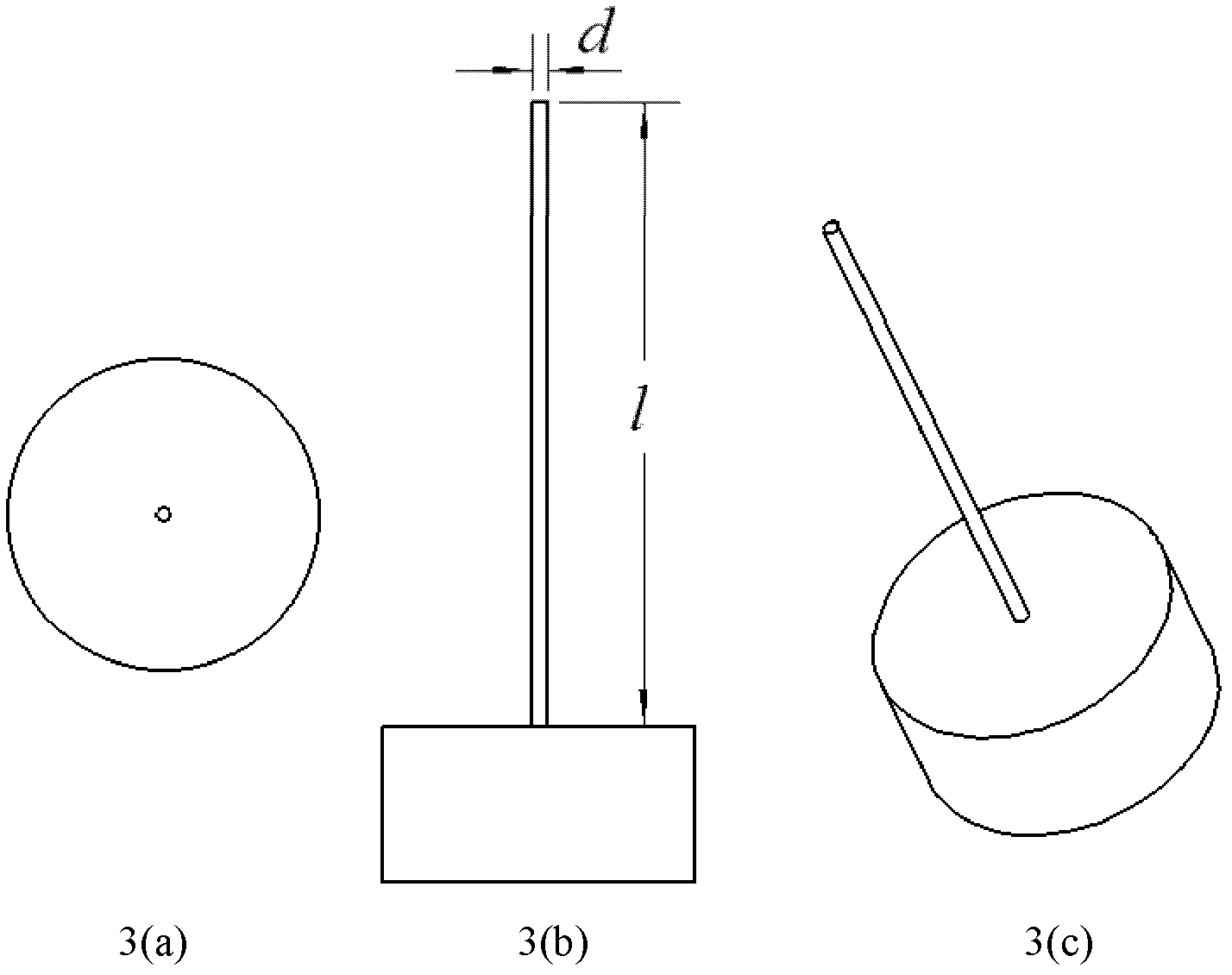

[0050] Described safety thimble, embodiment such as attached image 3 As shown, it is set in the sleeve and is used to lift the chip under the drive of the driving device to peel off the die-bonding film. The value of the force is between the chip peeling force and the chip damage force.

[0051] (1) The lower end is fixed on the thimble seat, and the upper end is against the thimble of the adhesive crystal film. It can be regarded as a sle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com